The Marvelous Mechanics of Self Tapping Screws: How They Work

Release Time:

2025-08-11

Source:

Understanding Self Tapping Screws

When it comes to assembly and construction, nothing quite compares to the efficiency of self tapping screws. These little heroes of the hardware world have revolutionized how we approach fastening tasks. But just how do they work their magic? Buckle up; we're diving into the nitty-gritty!

What Are Self Tapping Screws?

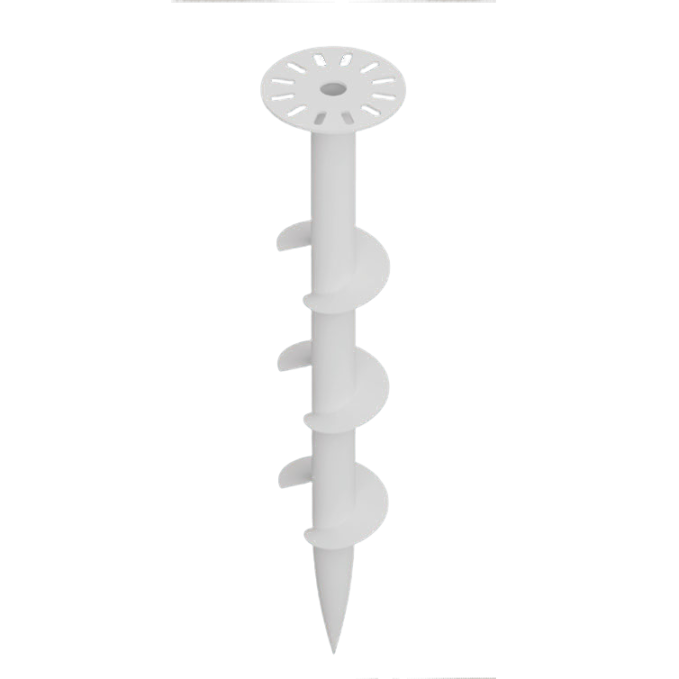

First off, let's get one thing straight: self tapping screws, or as the pros call them, STS, aren't your average fasteners. Unlike traditional screws that require a pre-drilled hole, self tapping screws create their own path. They're designed with a sharp tip that bores into materials, saving you time and hassle. Talk about a game changer!

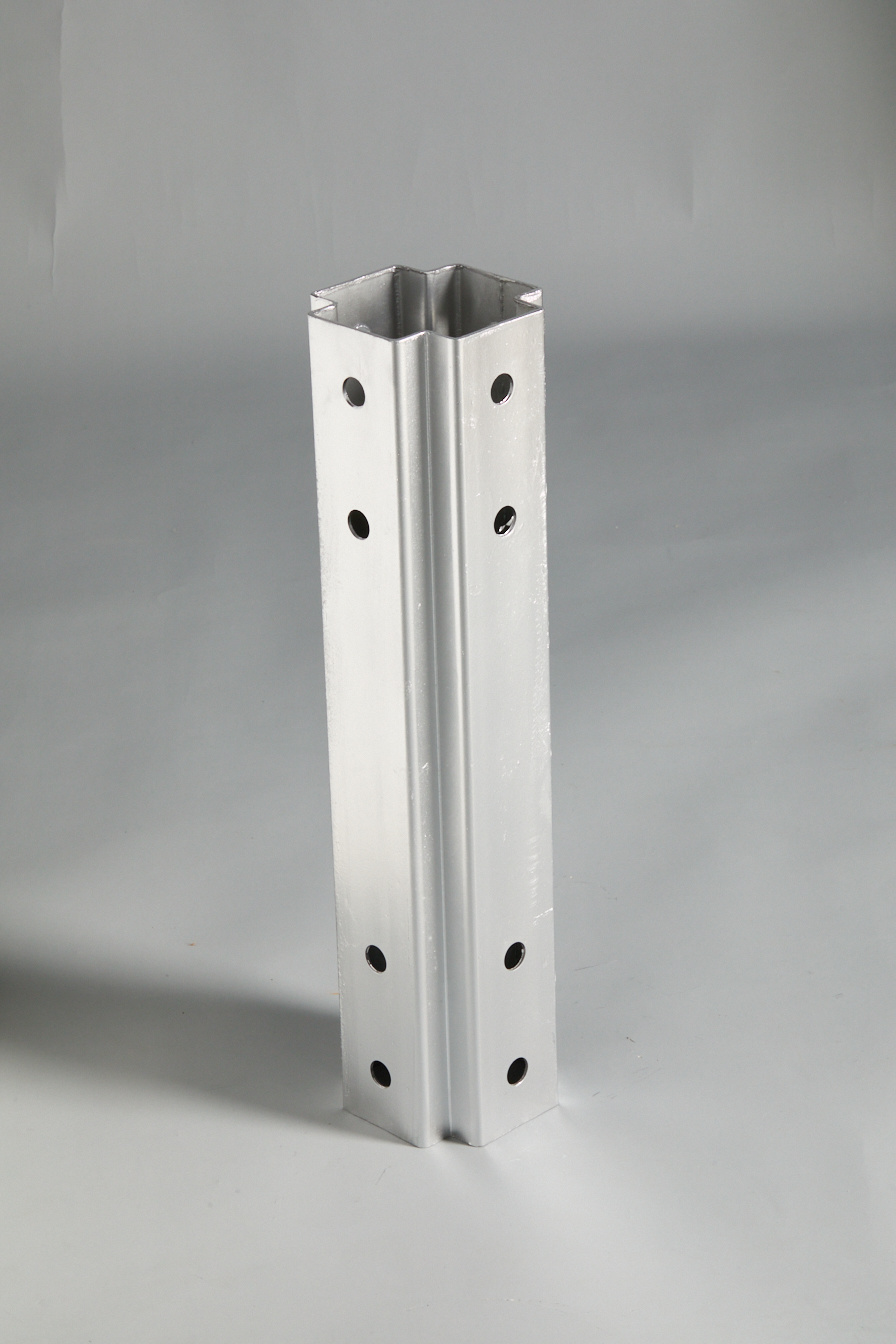

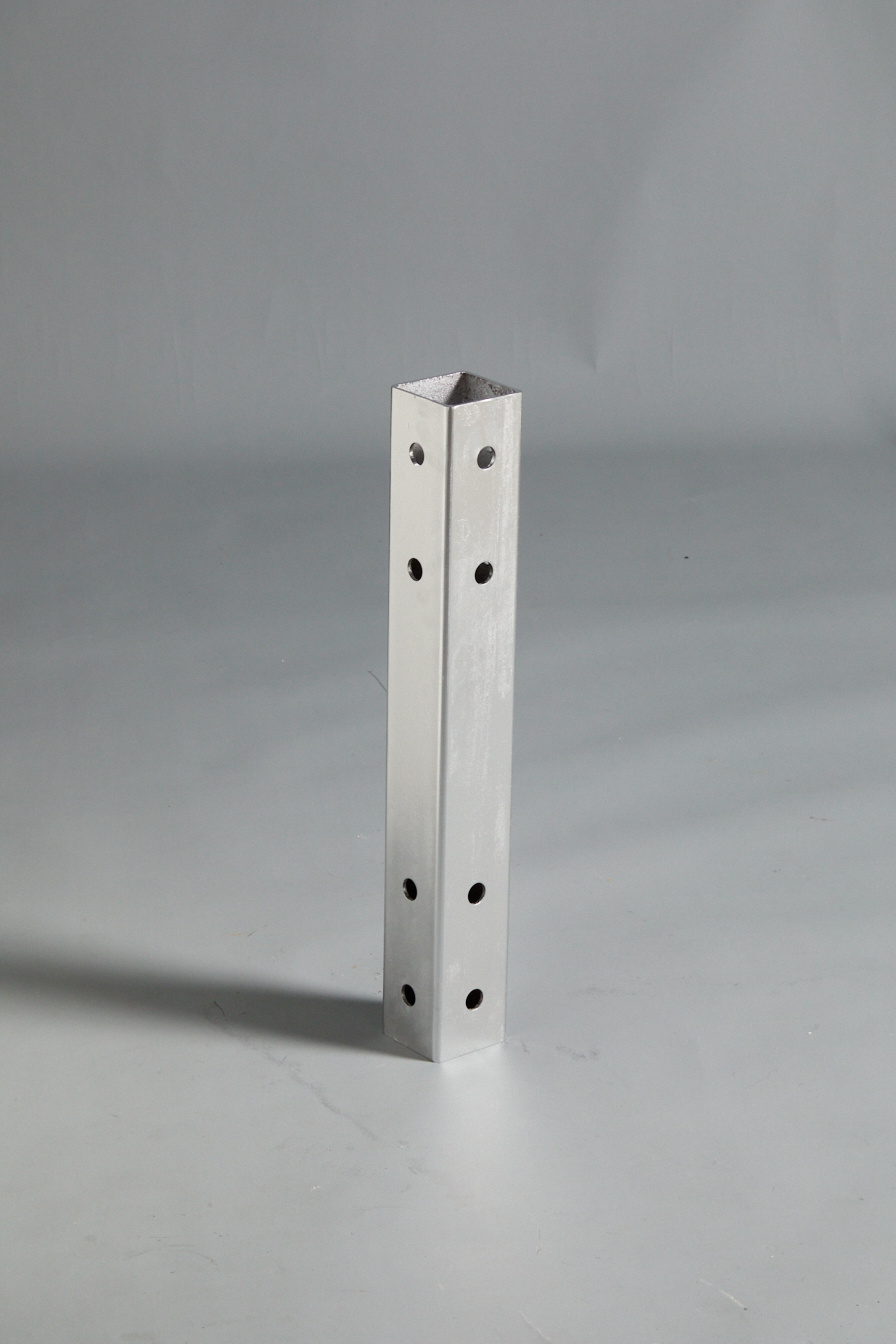

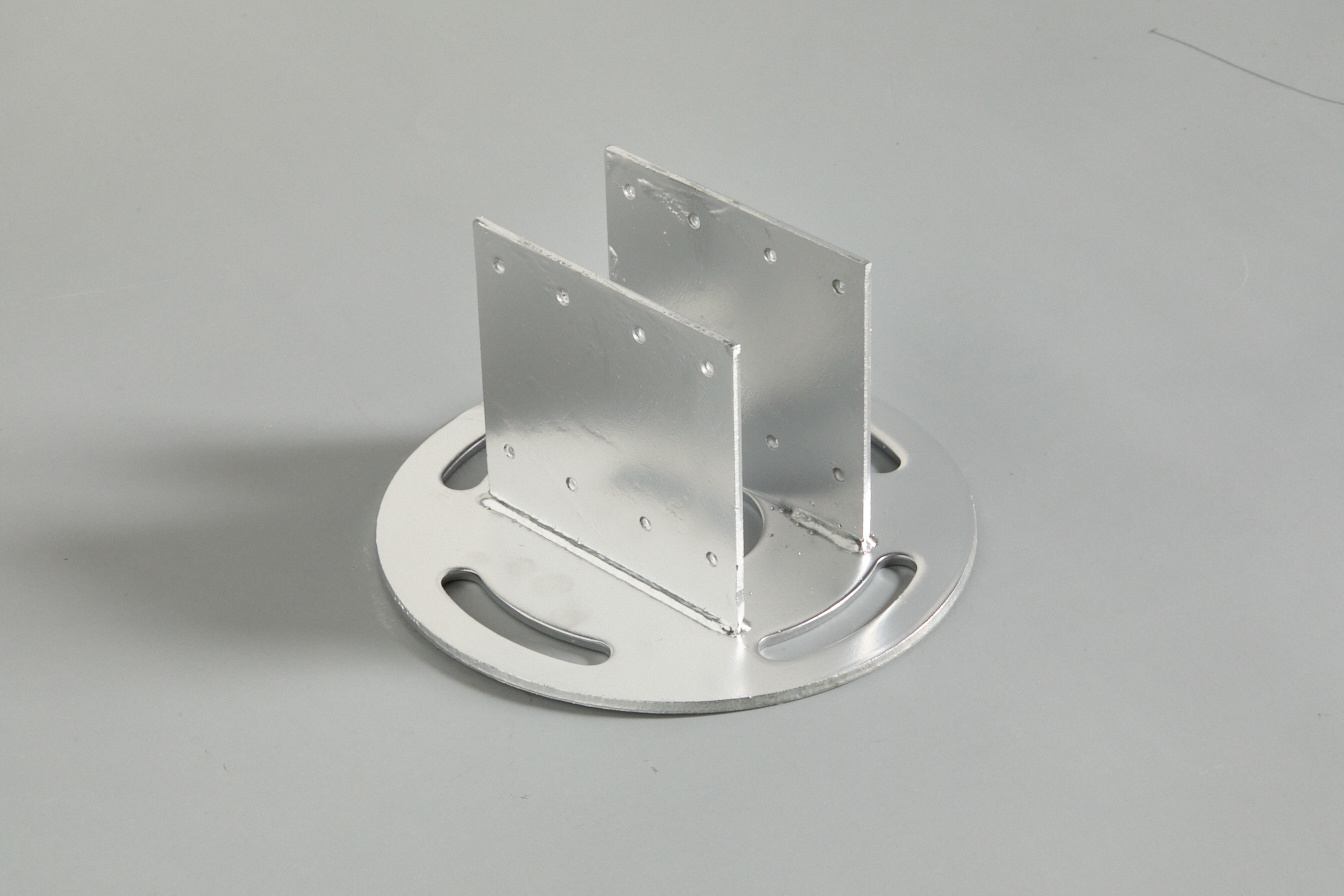

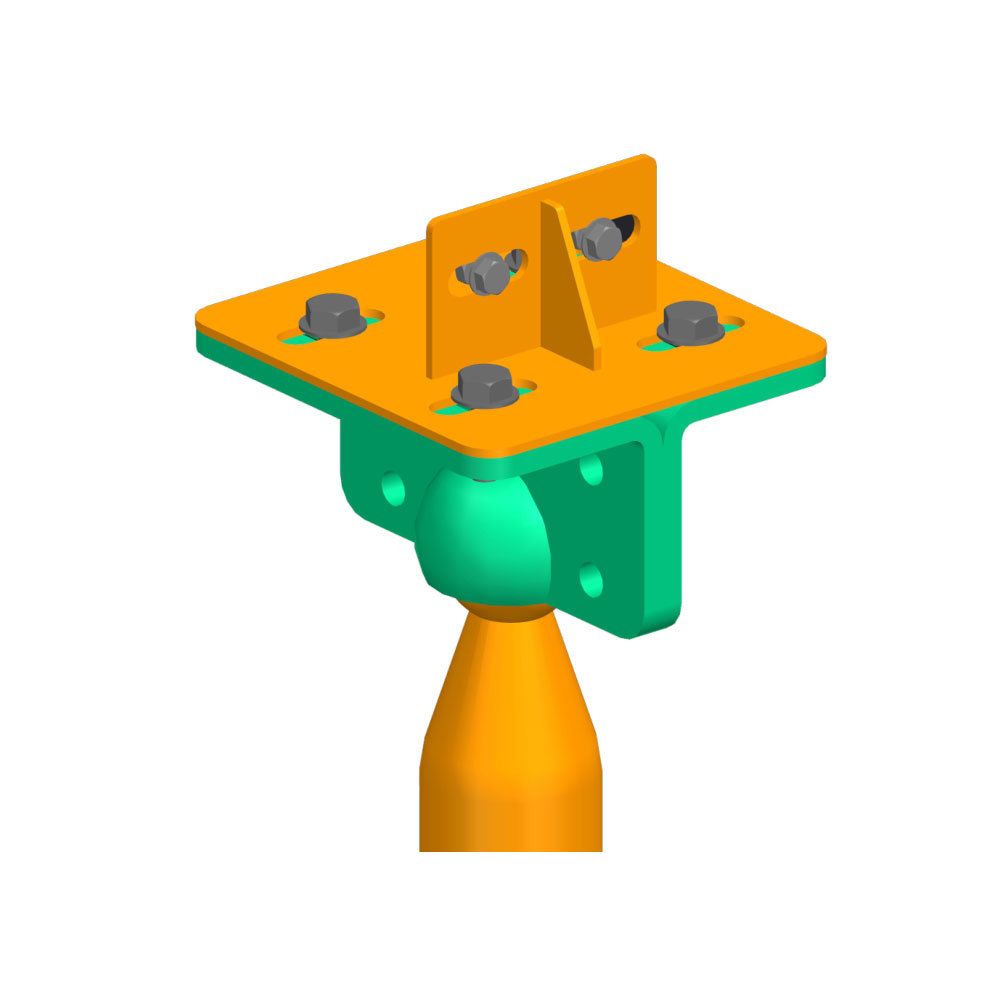

The Ingenious Design

Now, let's peek under the hood. The magic of self tapping screws lies in their unique design. The threads on the screw are specially crafted to grip the material tightly as they turn. When you drive them in, the sharp point pierces the surface, allowing the screw to tap its way into the material. It's like watching a dance where the screw leads, effortlessly guiding itself into place.

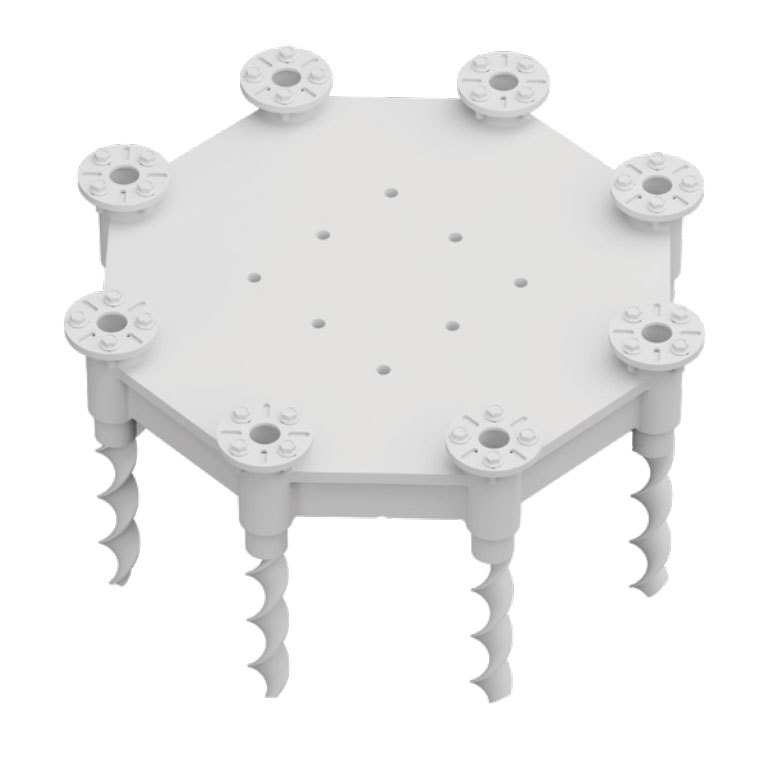

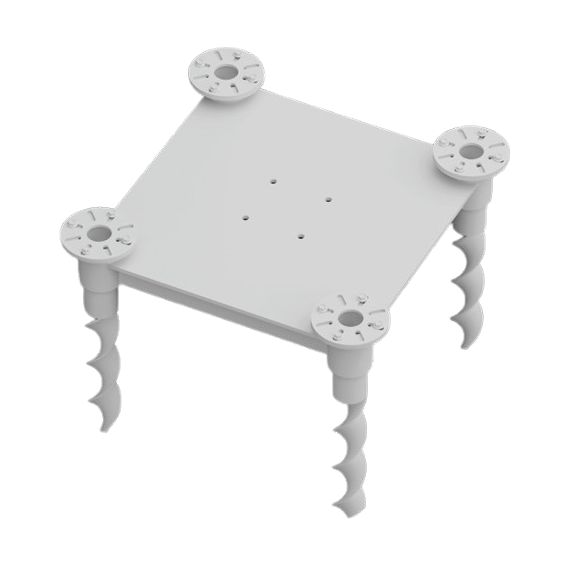

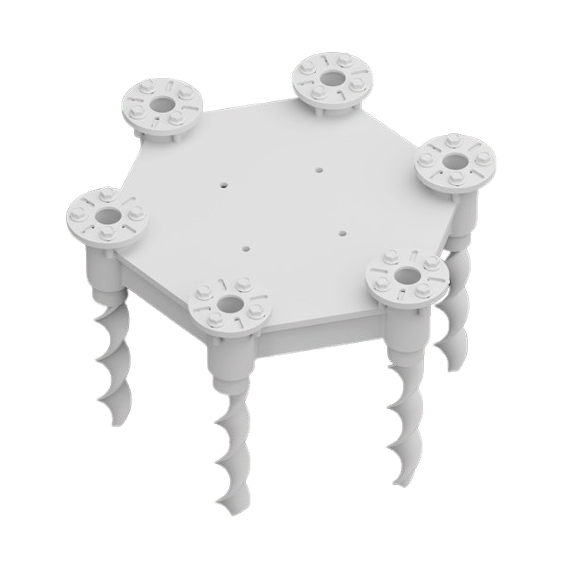

Types of Self Tapping Screws

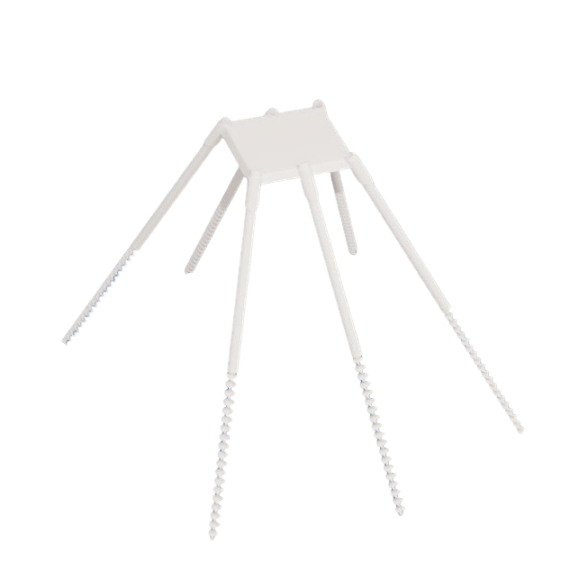

Believe it or not, there are several types of self tapping screws, each tailored for different tasks. Let's break it down:

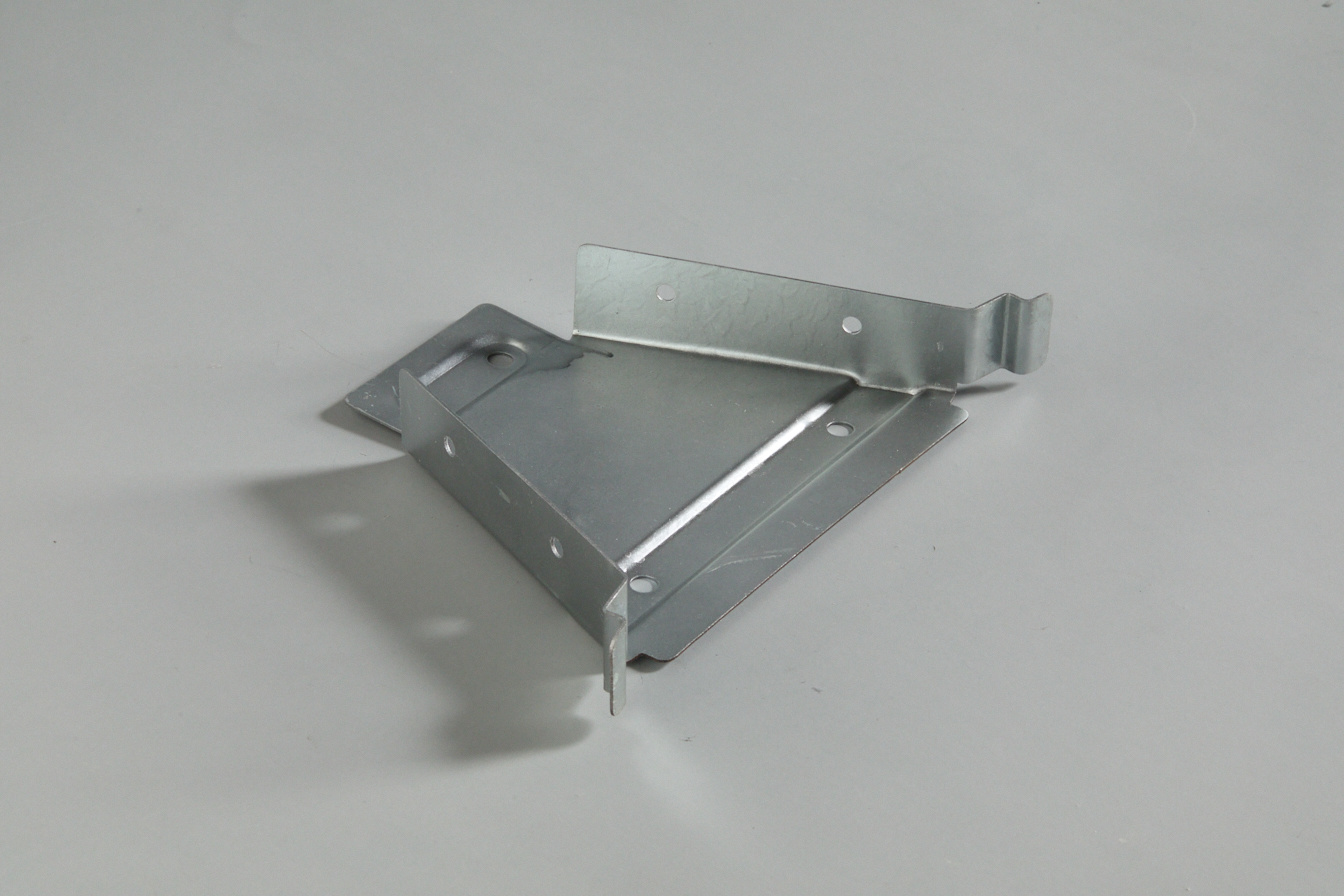

- Metal Self Tapping Screws: Perfect for fastening metal sheets, these bad boys come with a hardened point to penetrate tough surfaces.

- Wood Self Tapping Screws: Designed for softer materials, these screws feature coarse threads for a tighter grip.

- Plastic Self Tapping Screws: Ideal for assembling plastic components, they provide a snug fit without cracking the material.

How Do They Work?

Alright, let's get into the meat of it. Picture this: you've got a piece of wood or metal, and you want to secure something to it. If you reach for a standard screw, you'd need to pre-drill a hole, which can be a real pain in the neck. But with self tapping screws, all you need is a power drill and a steady hand!

As you drive in the screw, the sharp tip first penetrates the surface. Then, as you continue to turn, the threads cut into the material, creating a tight fit. It's like the screw is saying, “Step aside, I've got this!” The result? A secure fastening without the need for additional tools - now that's convenience!

Benefits Galore!

What's not to love about self tapping screws? Here are just a few reasons why they've become a staple in every DIY enthusiast's toolkit:

- Time-Saving: Forget about pre-drilling; these screws get the job done faster.

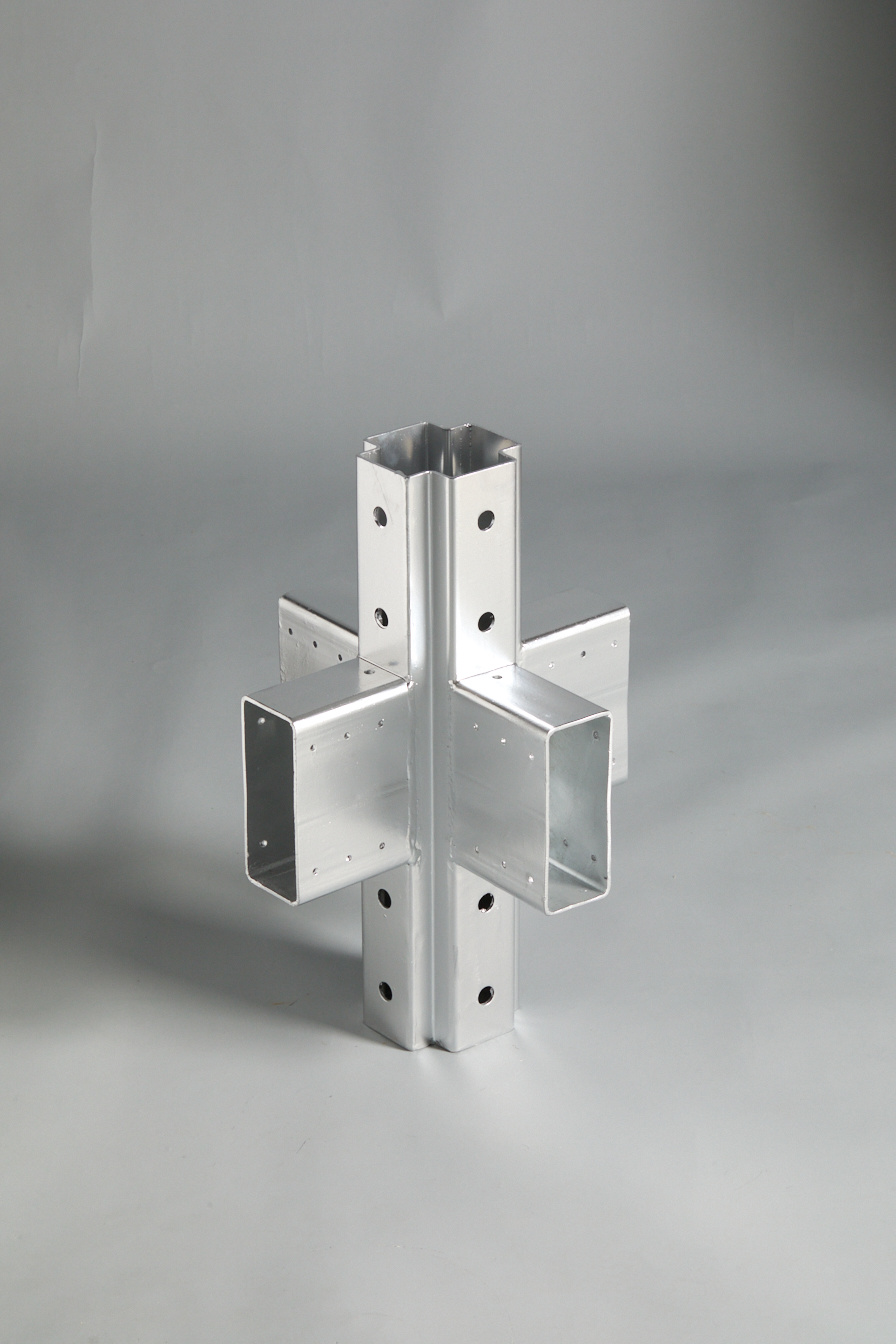

- Versatility: Use them on various materials, from wood to metal to plastic.

- Sturdiness: Once they're in, they stay put - no wobbling here!

Common Applications

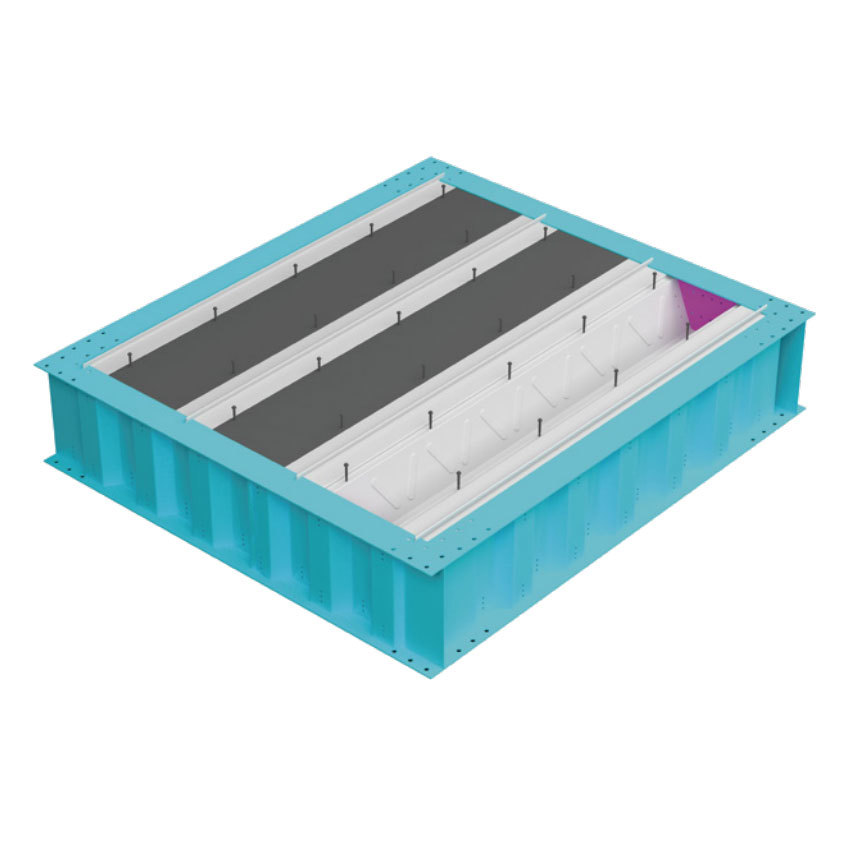

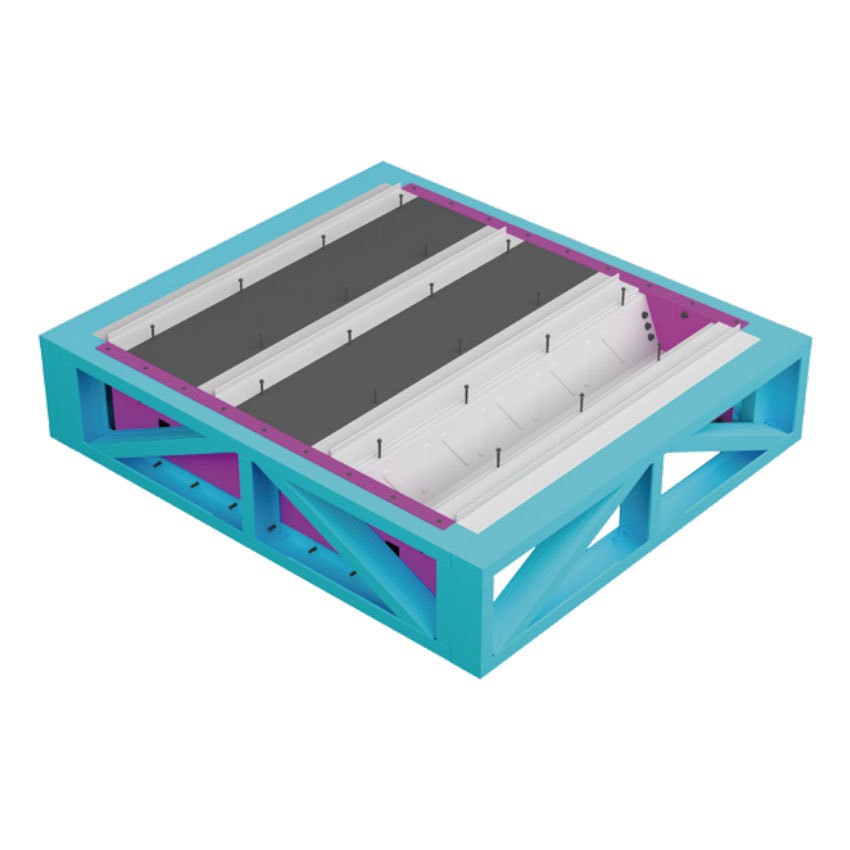

So, where can you use self tapping screws? The possibilities are endless! From building furniture to assembling outdoor structures, these screws are often the unsung heroes. You'll find them holding together:

- Furniture

- Sheet metal

- Wooden decks

- Plastic components

Are There Any Drawbacks?

While self tapping screws are fantastic, they're not without their quirks. For instance, if you're working with very hard materials, there's a chance the screw could break or strip. Ouch! That's why it's crucial to choose the right type for your project. And don't forget to use a proper drill speed; too fast can lead to a world of hurt. Slow and steady wins the race!

Final Thoughts

In conclusion, self tapping screws are the unsung heroes of the fastening world. With their unique ability to create their own holes and grip materials tightly, they save time and add efficiency to any project. So, the next time you're gearing up for a DIY endeavor, remember these little wonders. They may just be the key to your success!

Related Information

HaoHeng Group

Address: Room 1808, Block A, Vanke Cloud City, Jiemei District, Xiamen City, Fujian Province

Business cooperation:

Copyright © HaoHeng (FuJian) Building Materials Technology Co, Ltd. All rights reserved