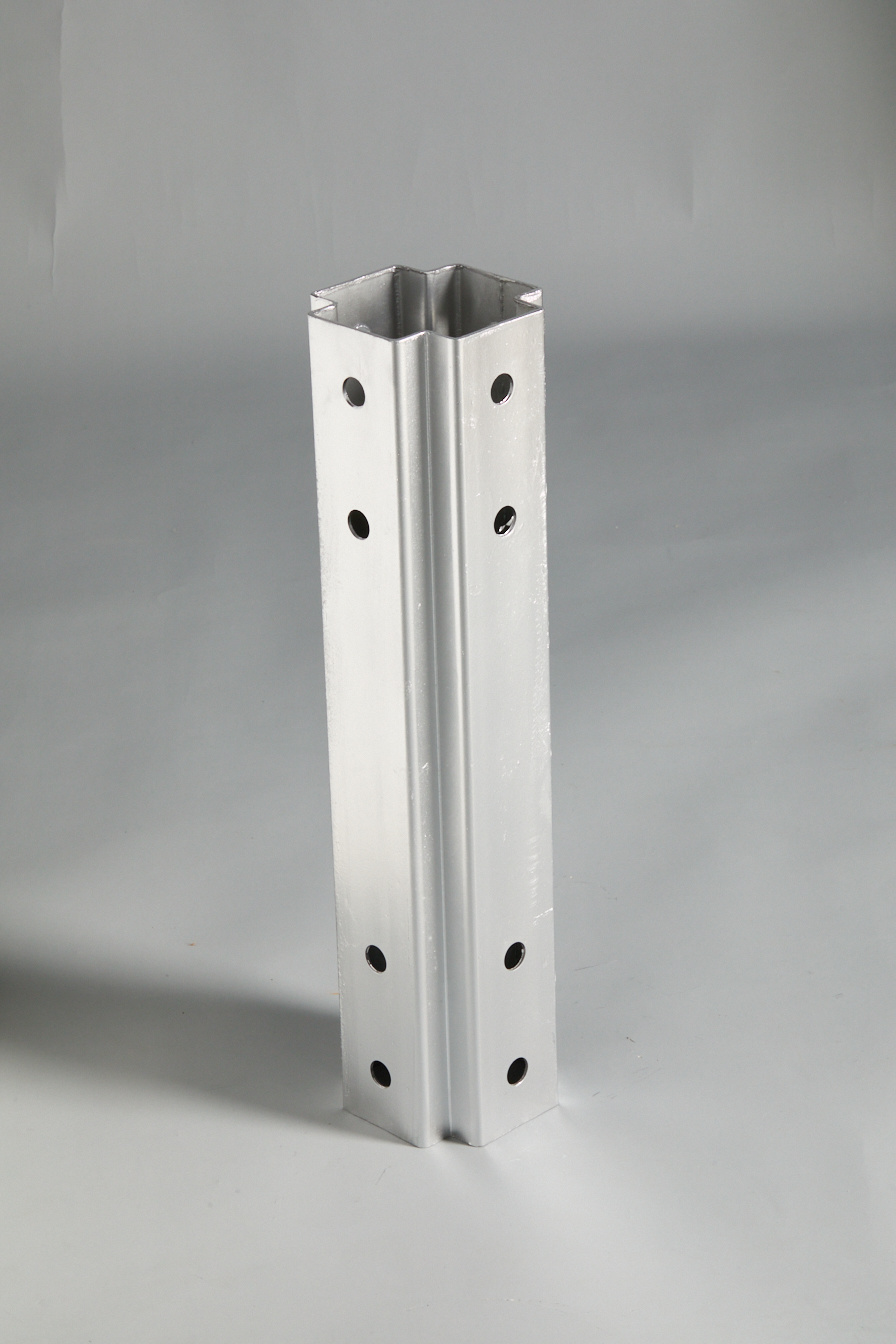

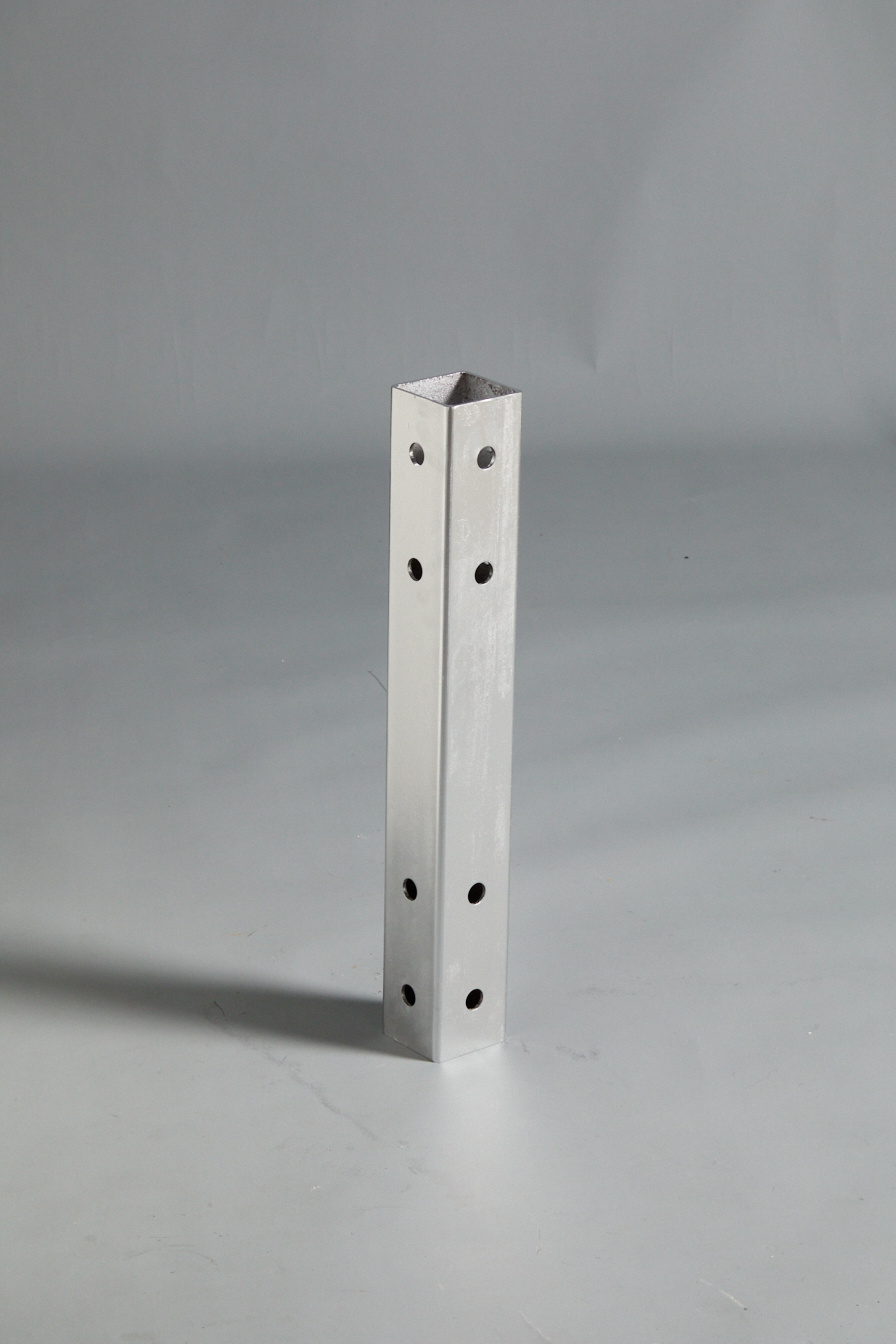

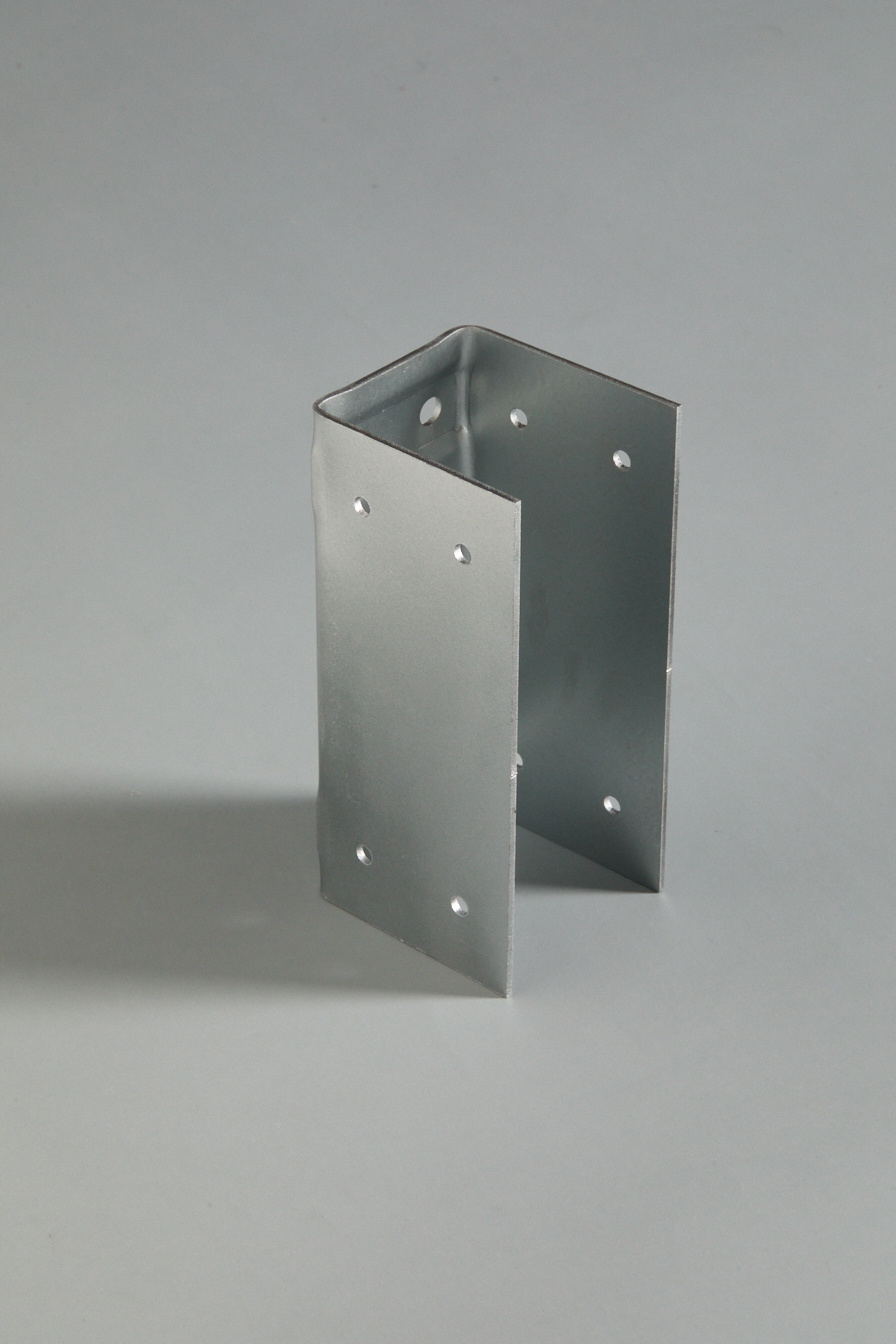

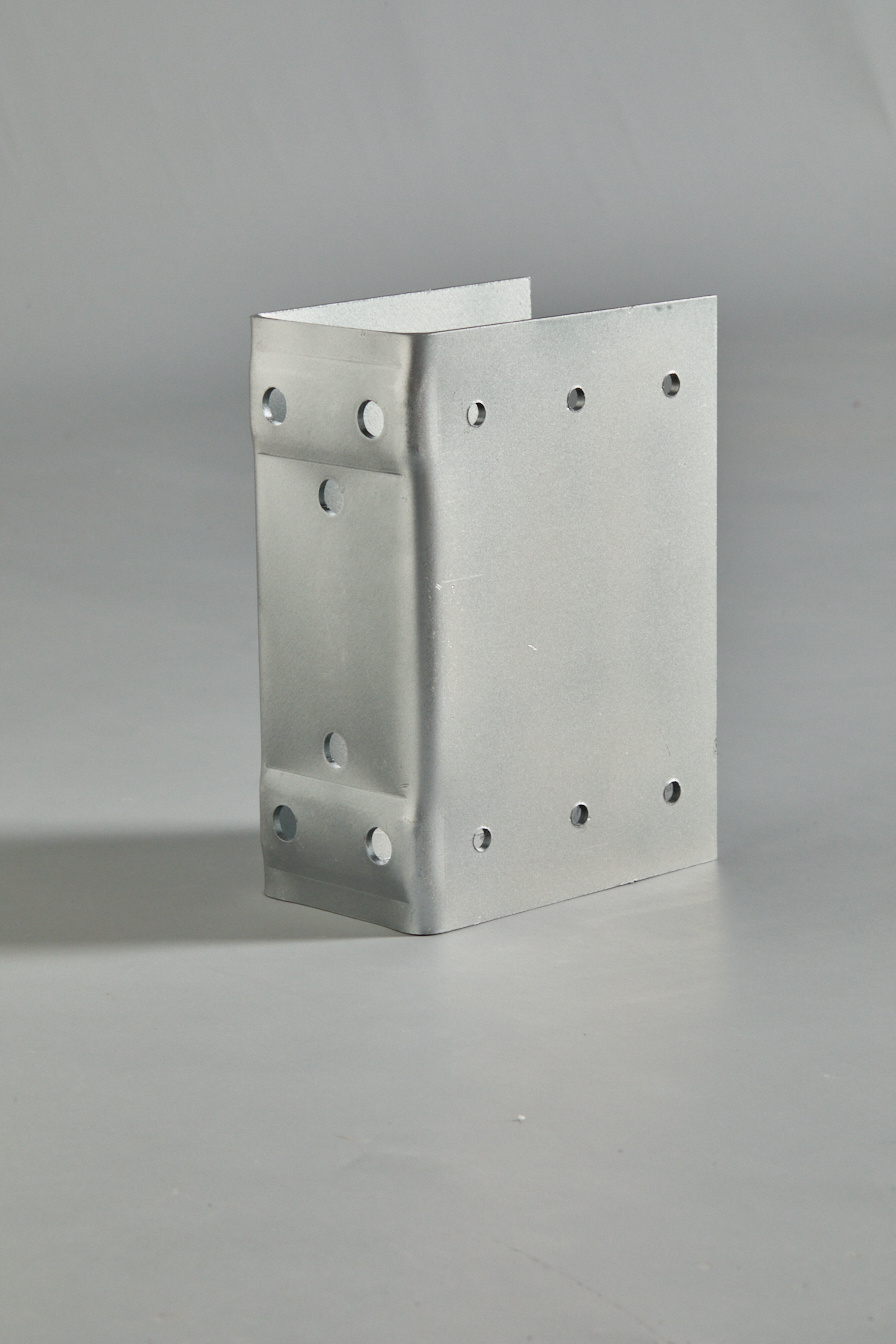

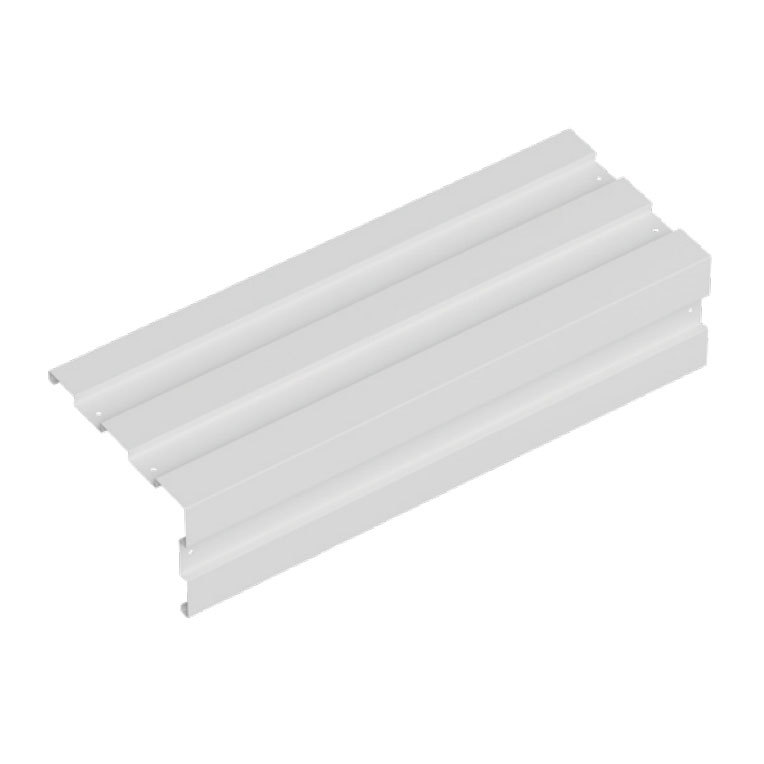

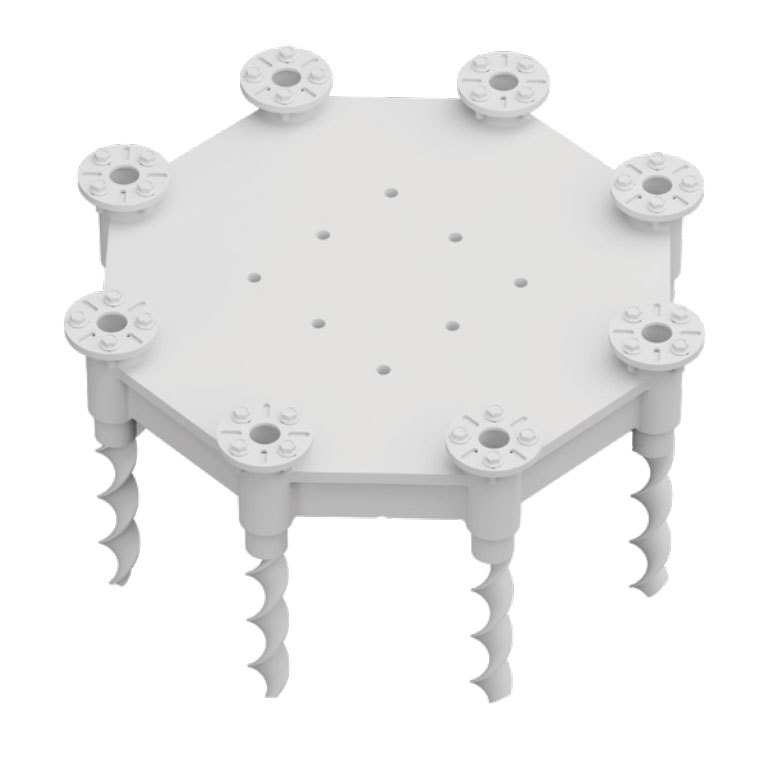

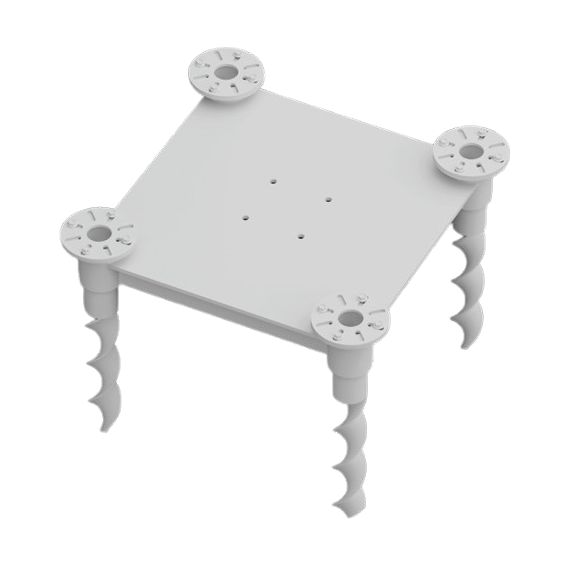

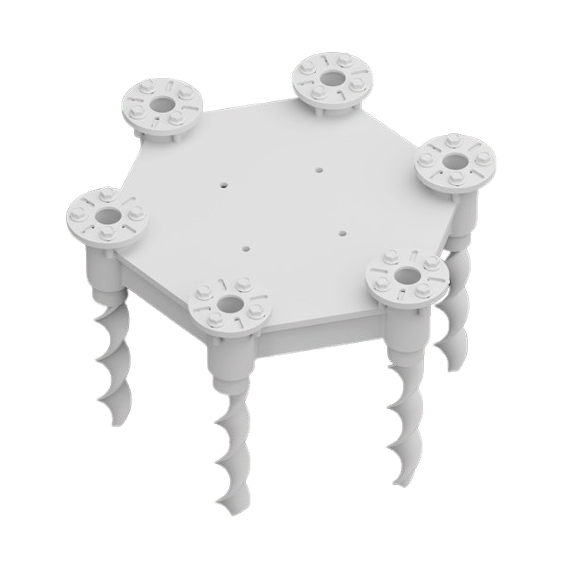

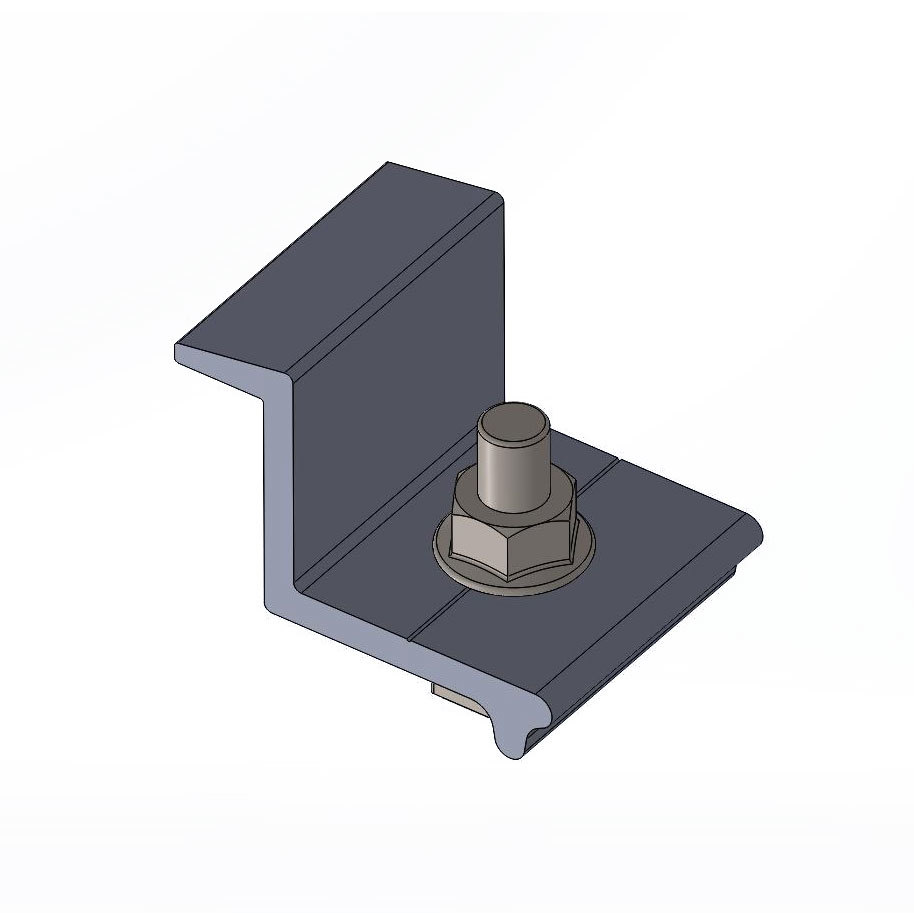

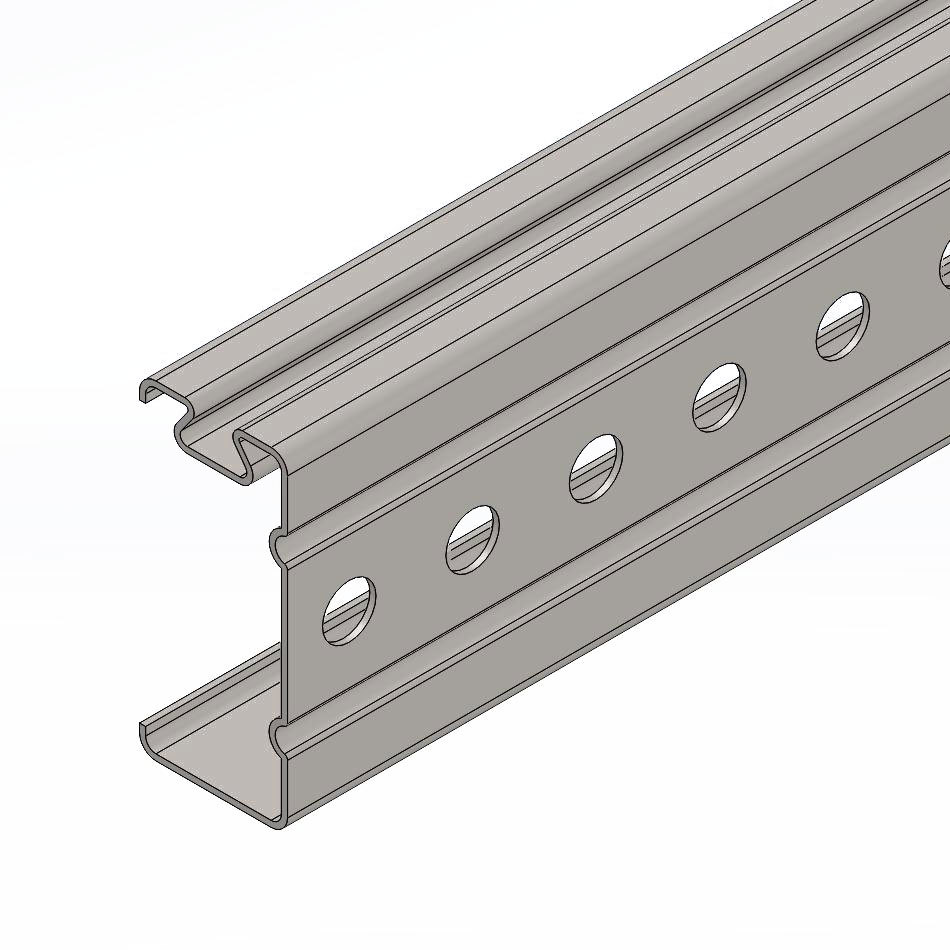

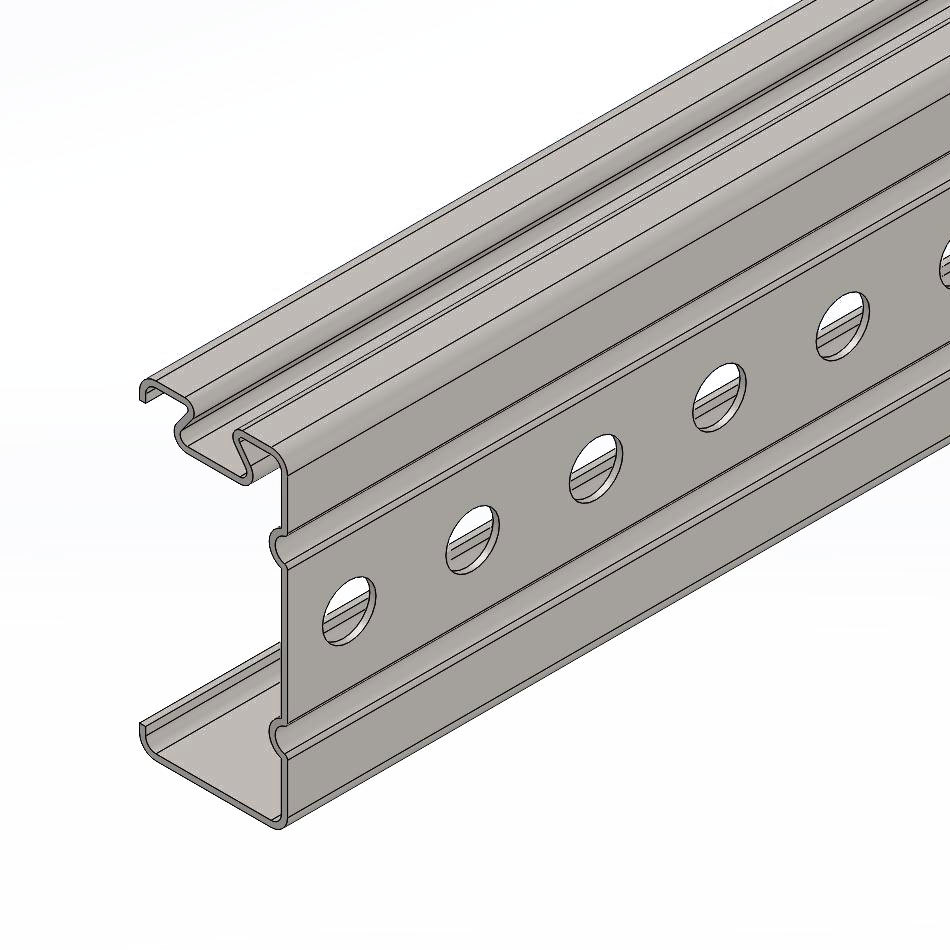

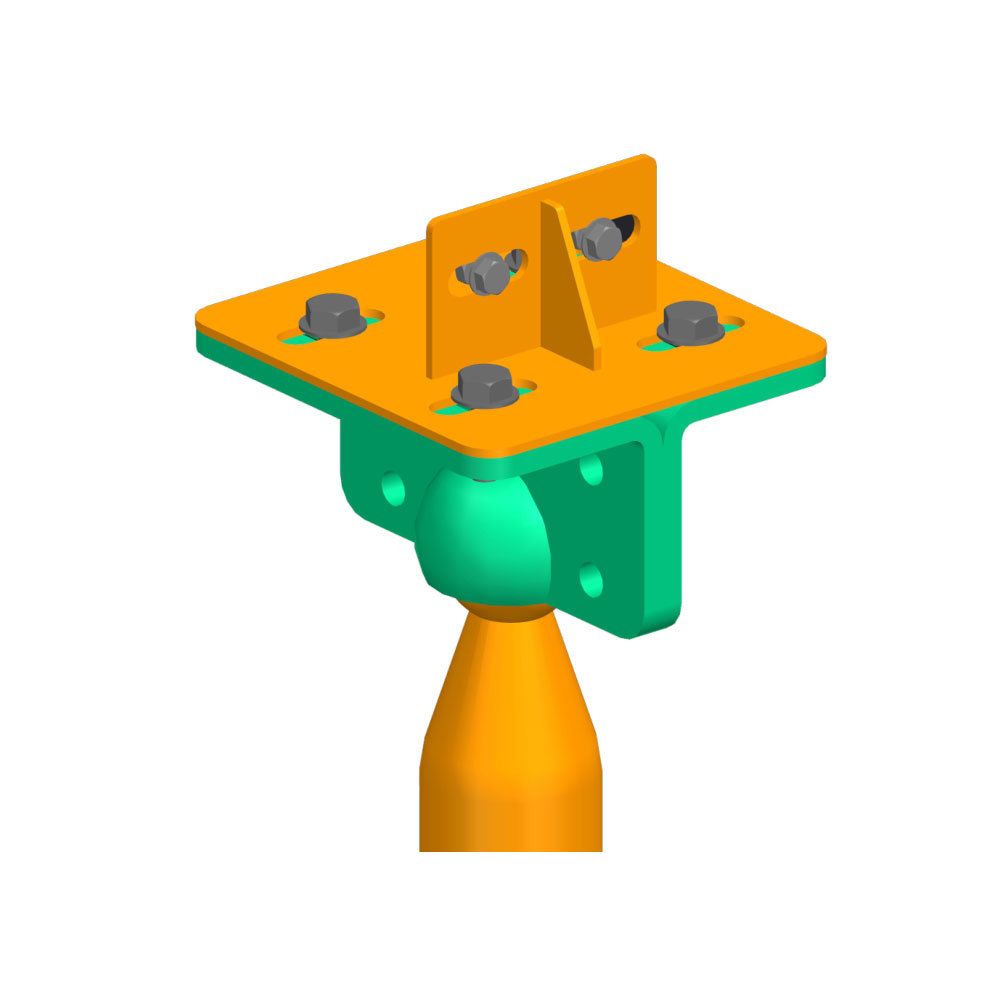

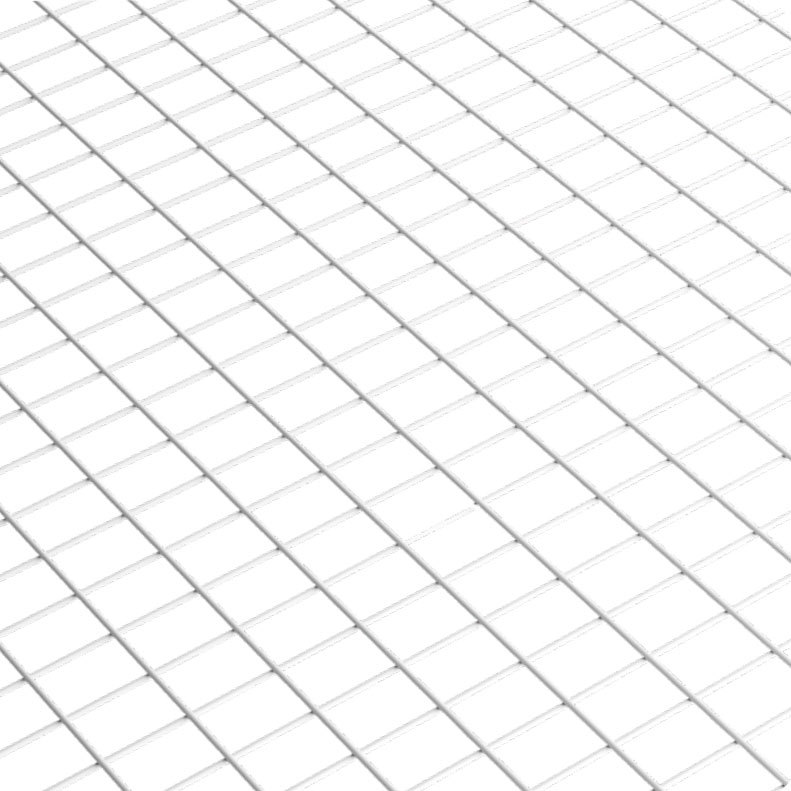

V-shaped floor beam

Classification:

Product Details

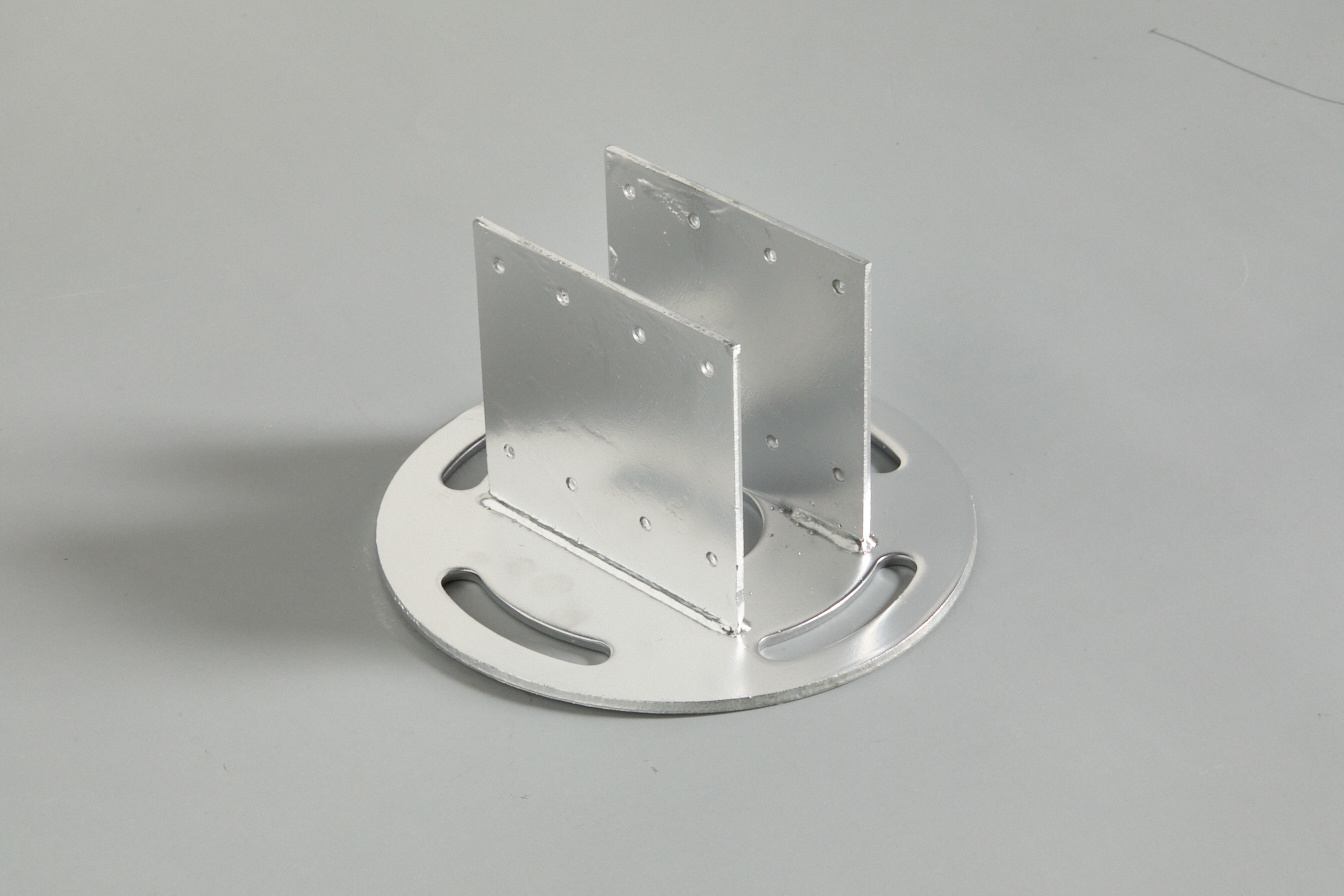

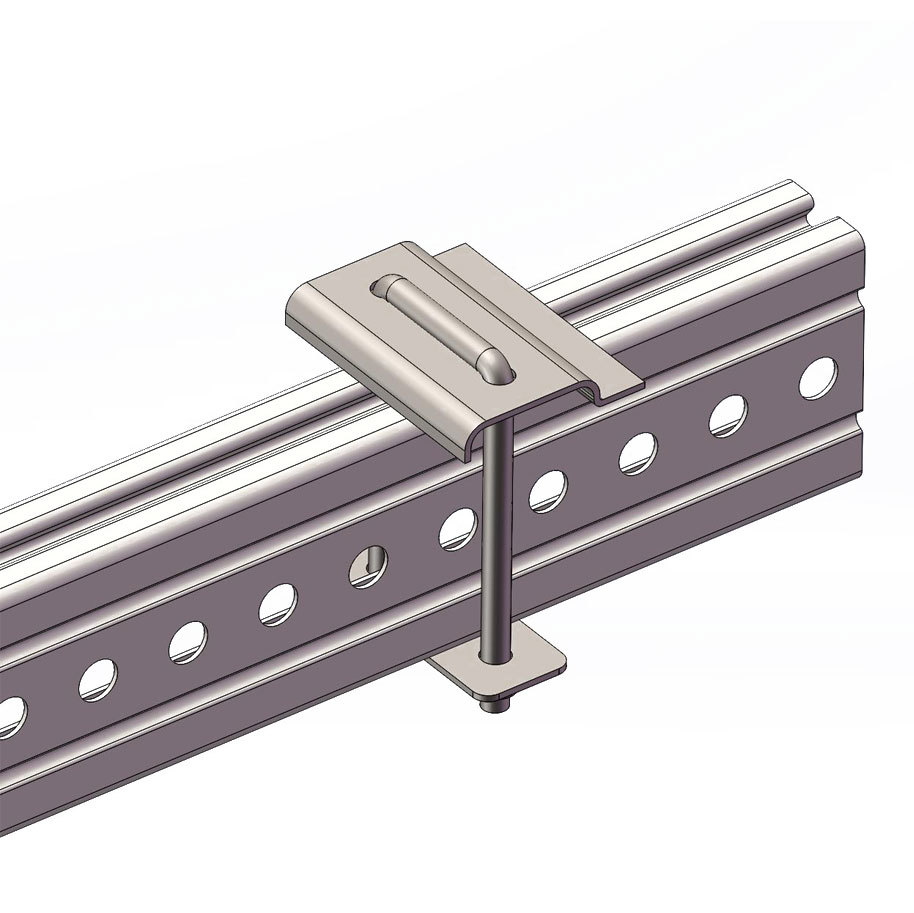

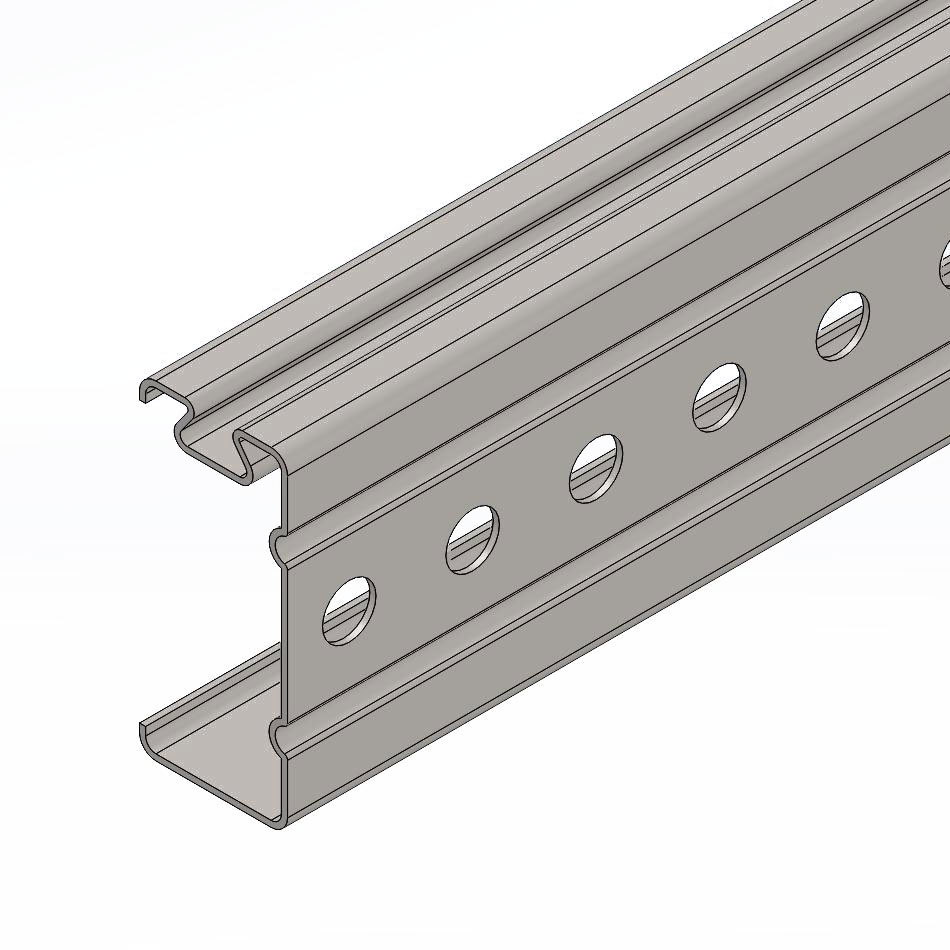

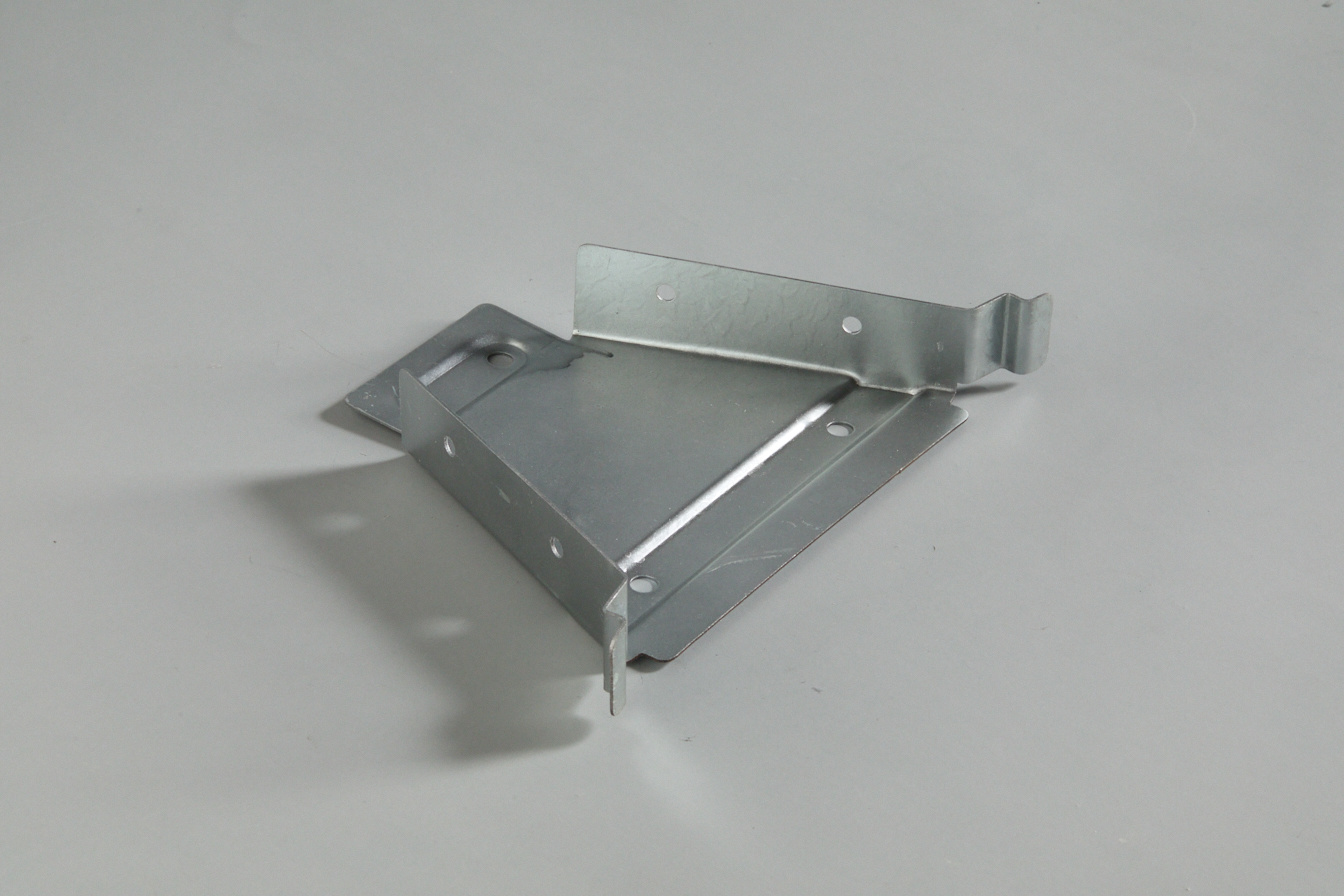

Material: Q355B, surface treated with galvanized 275g/㎡ or galvanized aluminum magnesium 275g/㎡.

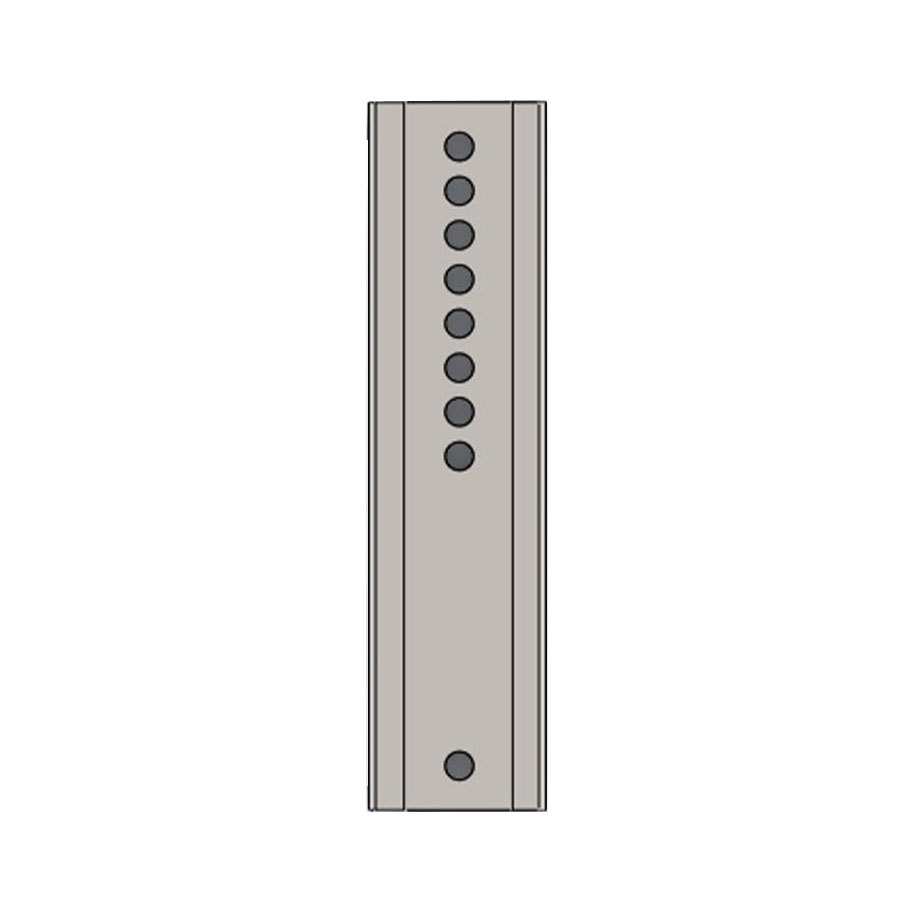

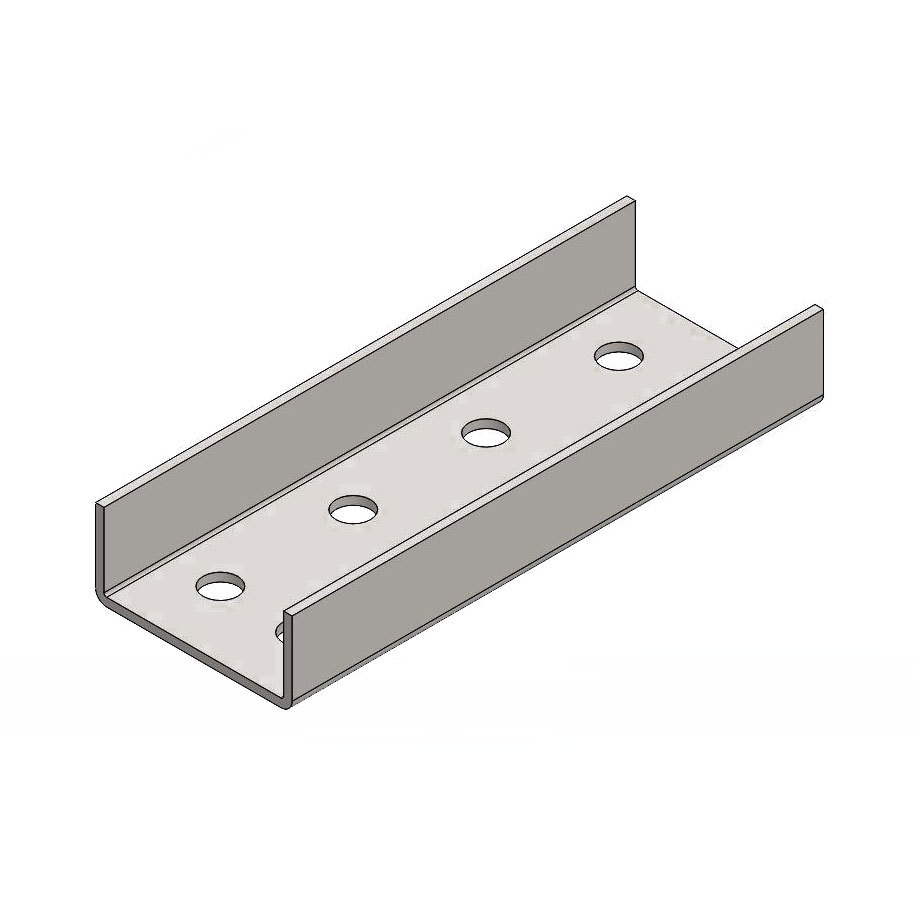

Specification parameters: 150mm x 370mm (customized length), effective width 370mm.

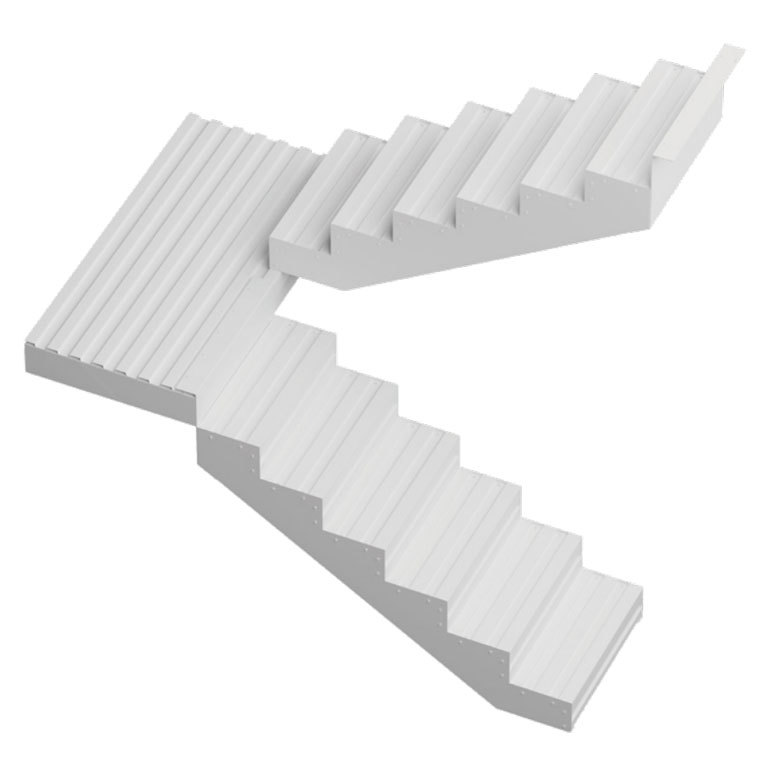

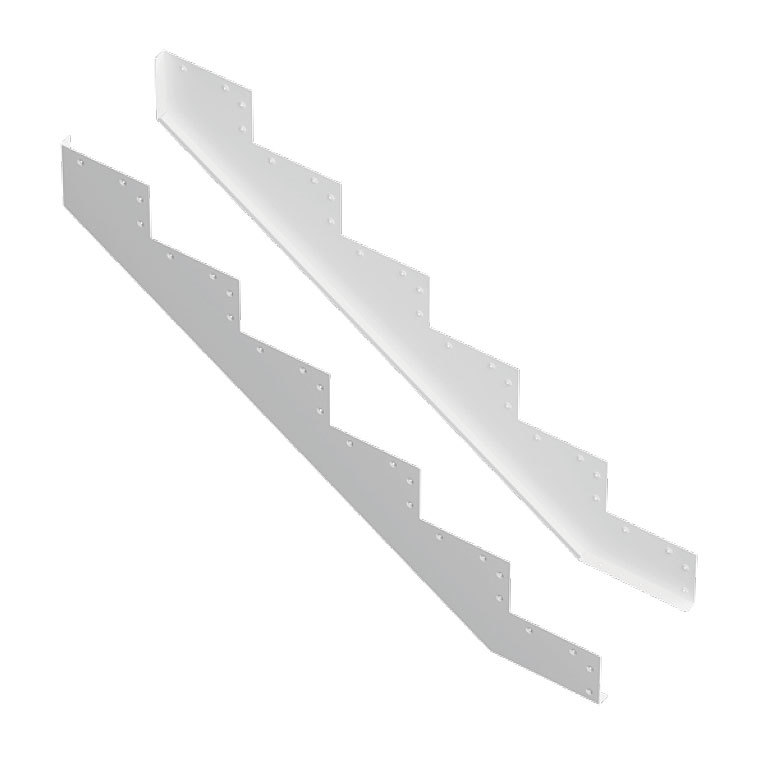

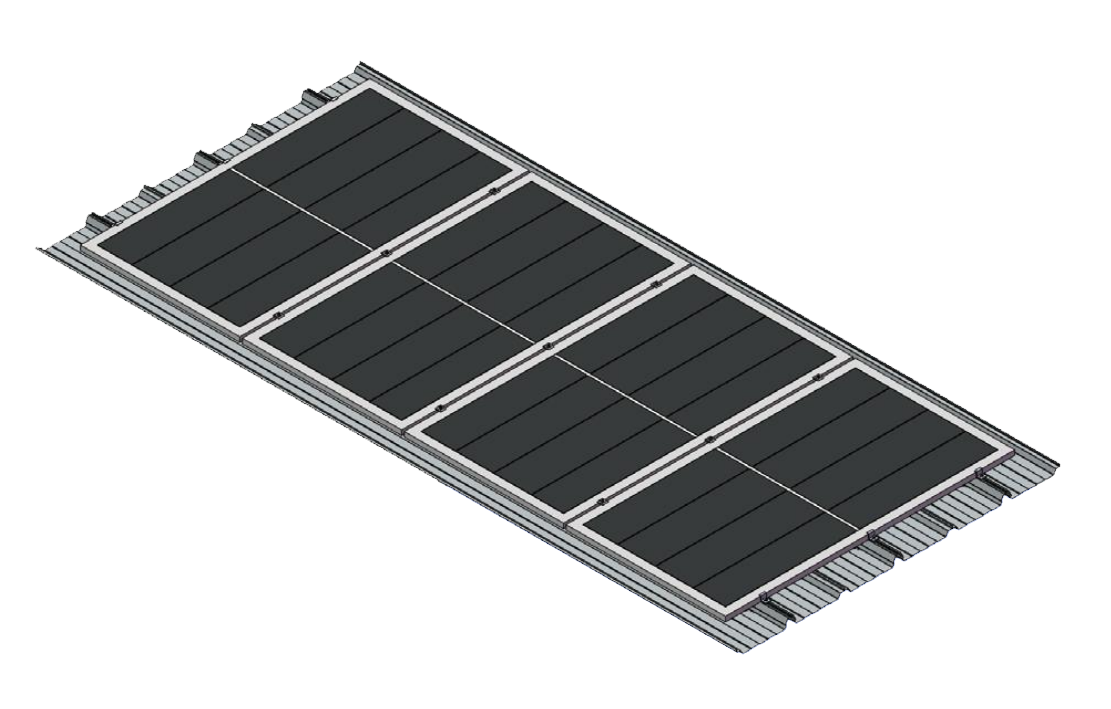

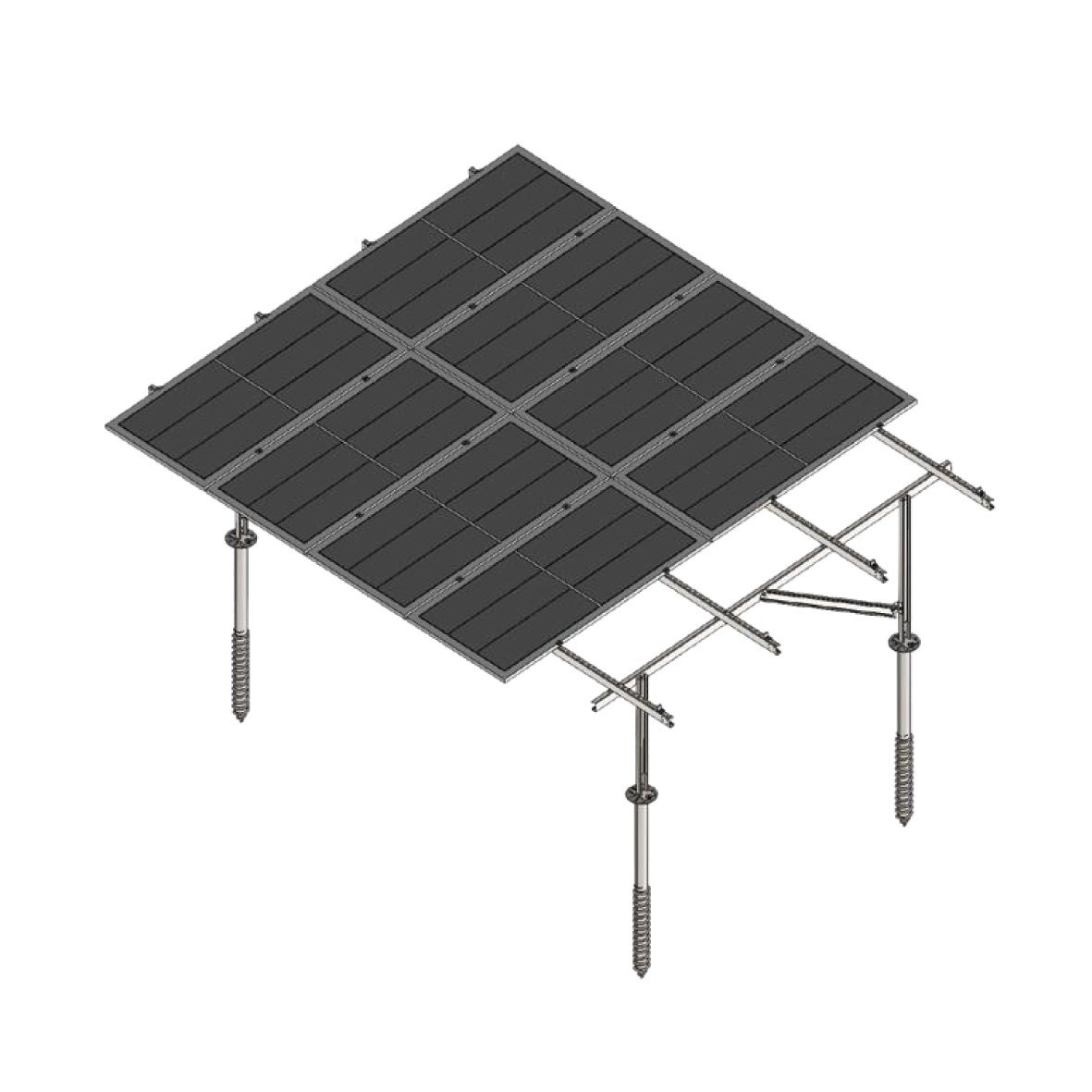

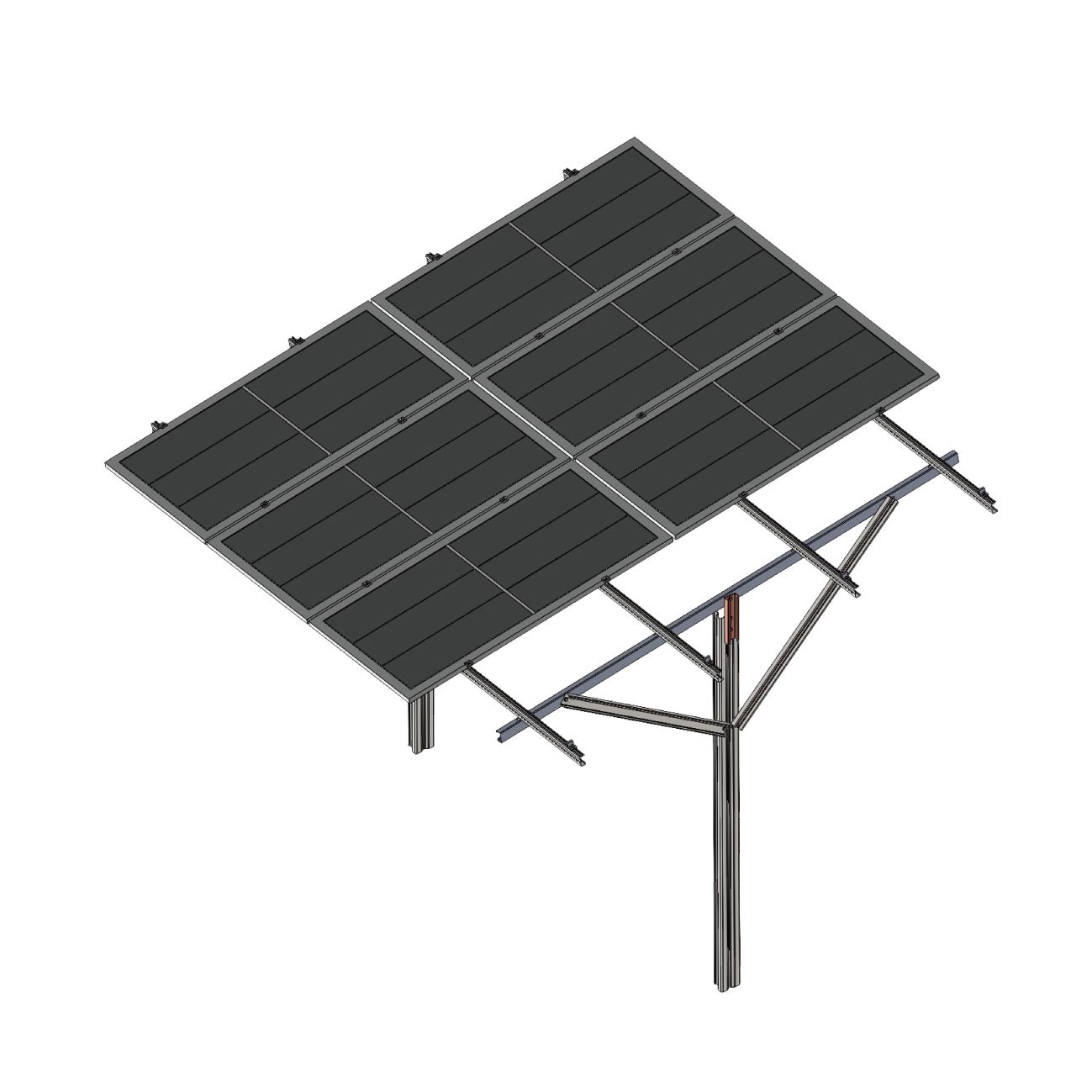

The Haoheng V-shaped floor beam, formed by cold bending, is a new type of lightweight and high load-bearing floor beam. With its stable structure, convenient installation, and cost-effective characteristics, it can replace traditional steel beams (H-shaped steel beams, cold-formed thin-walled steel truss beams, cross shaped beams, and deep U-shaped beams) and is widely used in building systems such as floor paving, floor renovation, wooden structures, prefabricated buildings, and light and heavy steel structures for public and civil buildings.

Patent number: ZL202122134764.8

Advantages of floor beam structural system

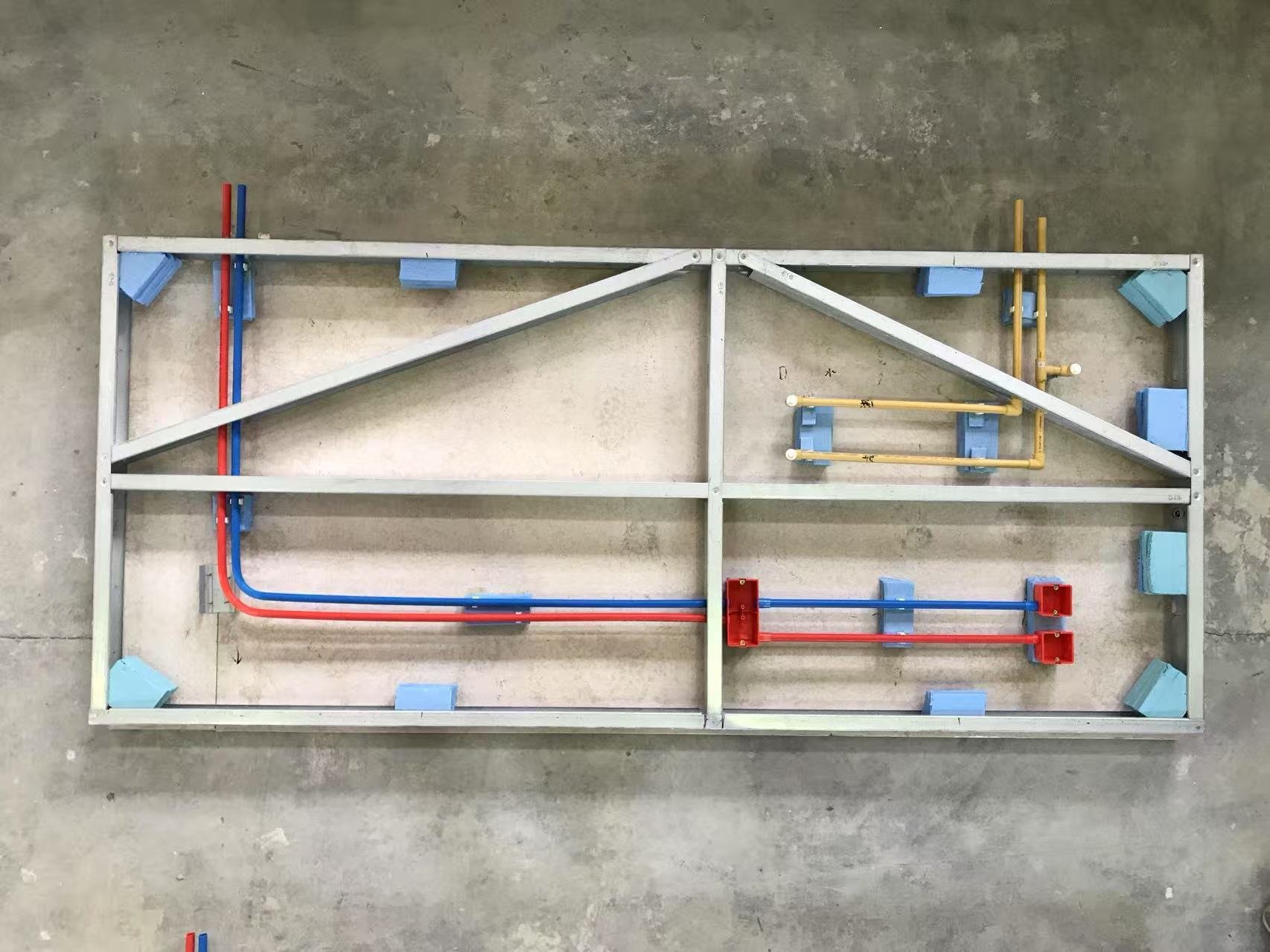

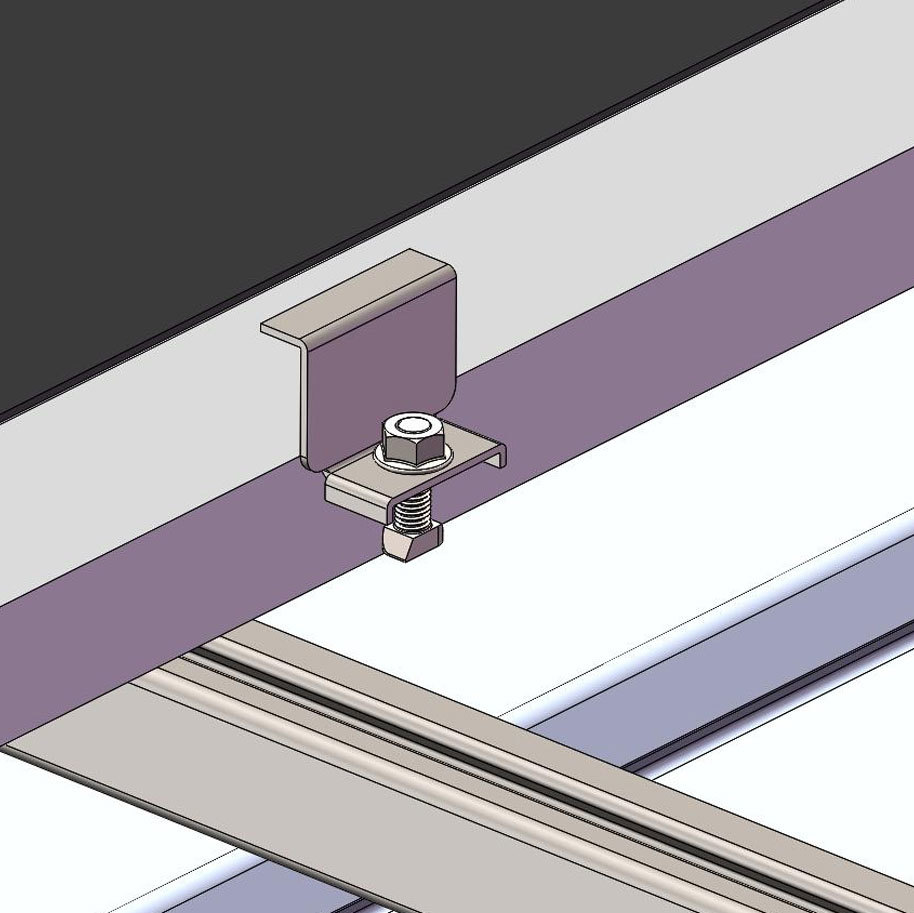

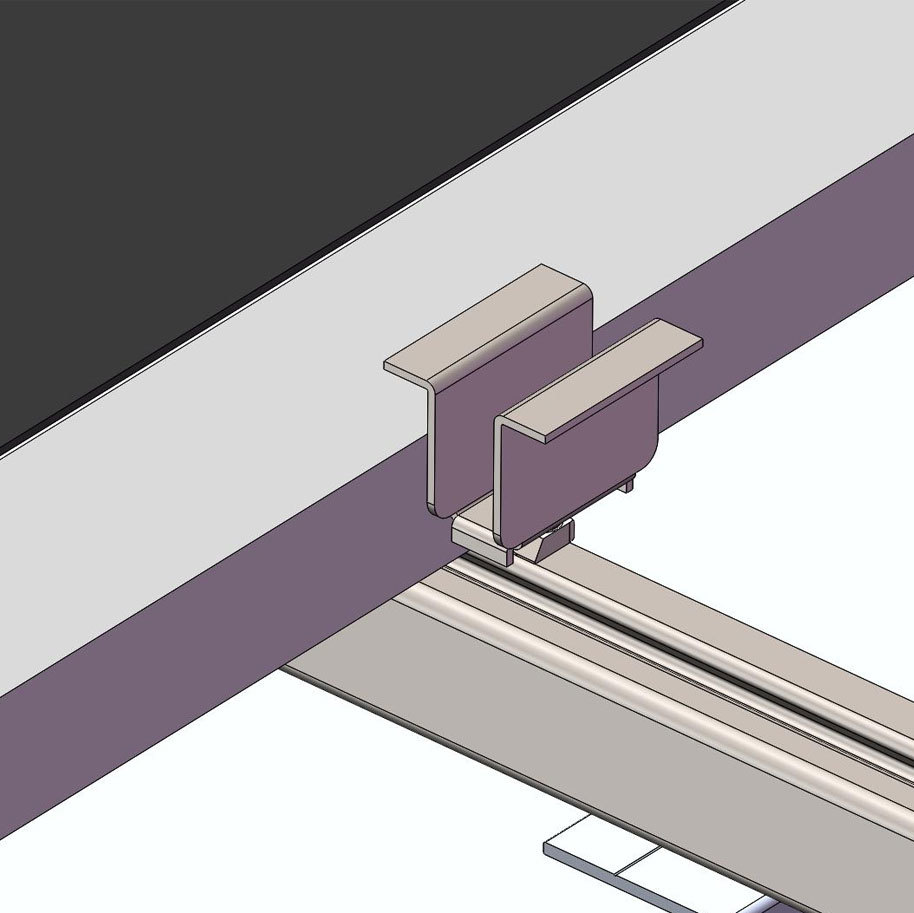

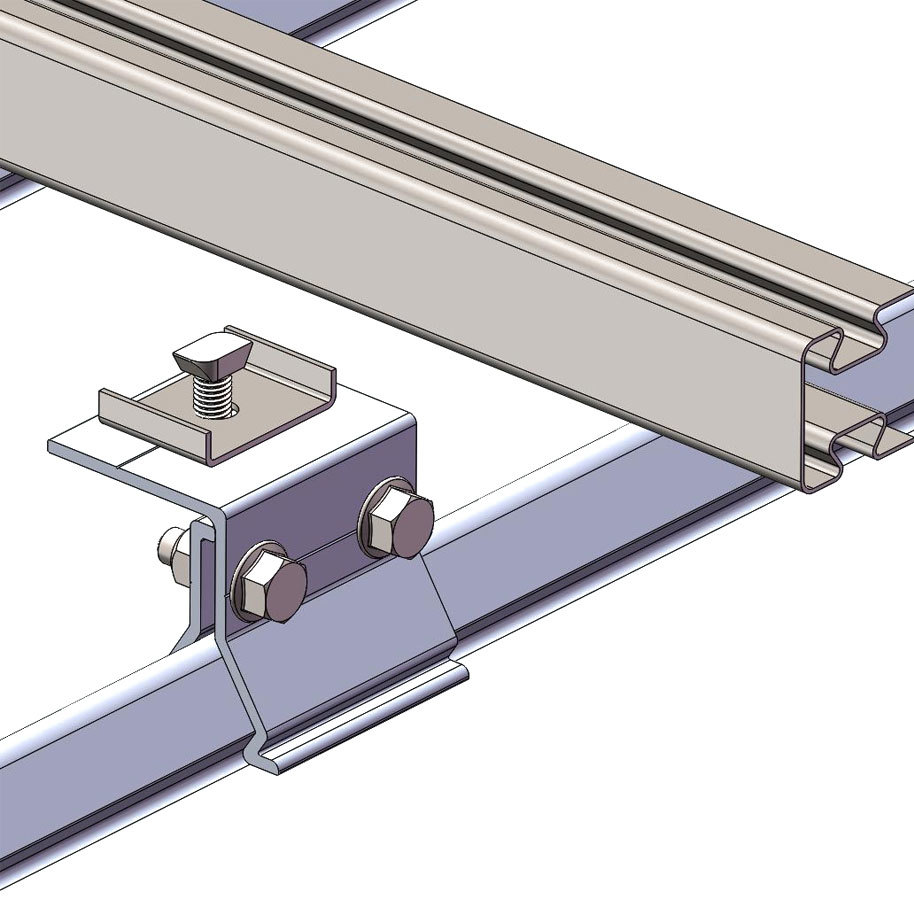

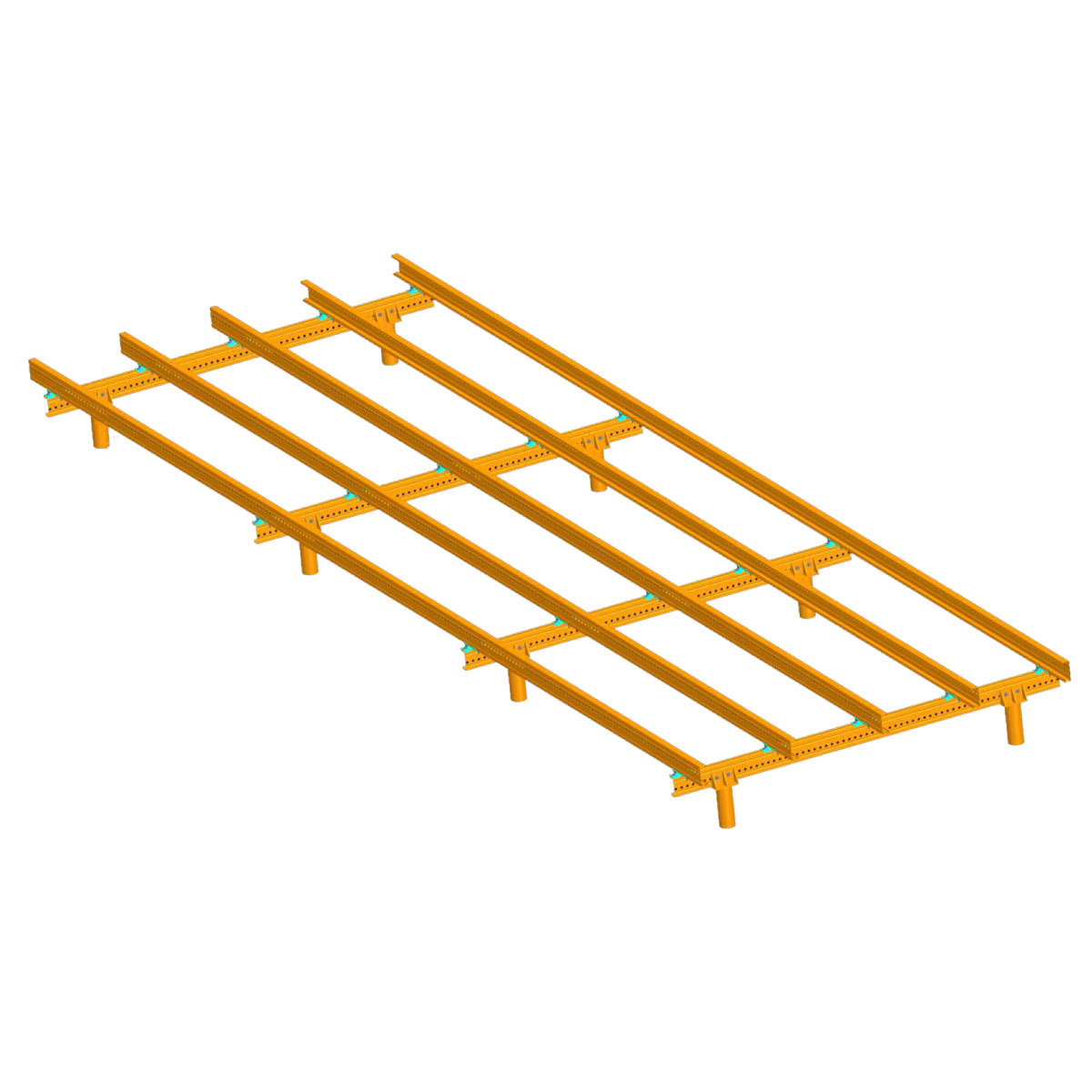

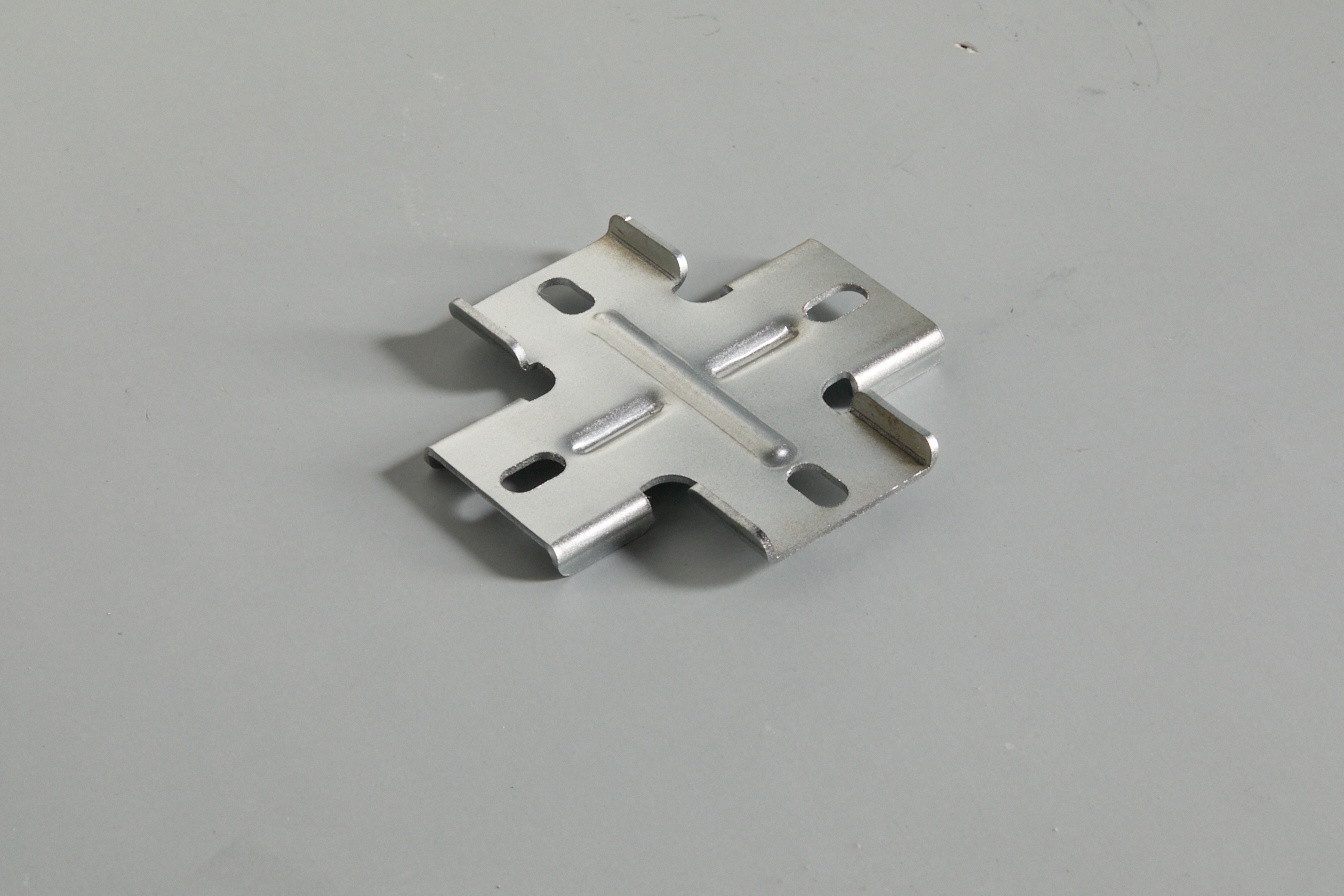

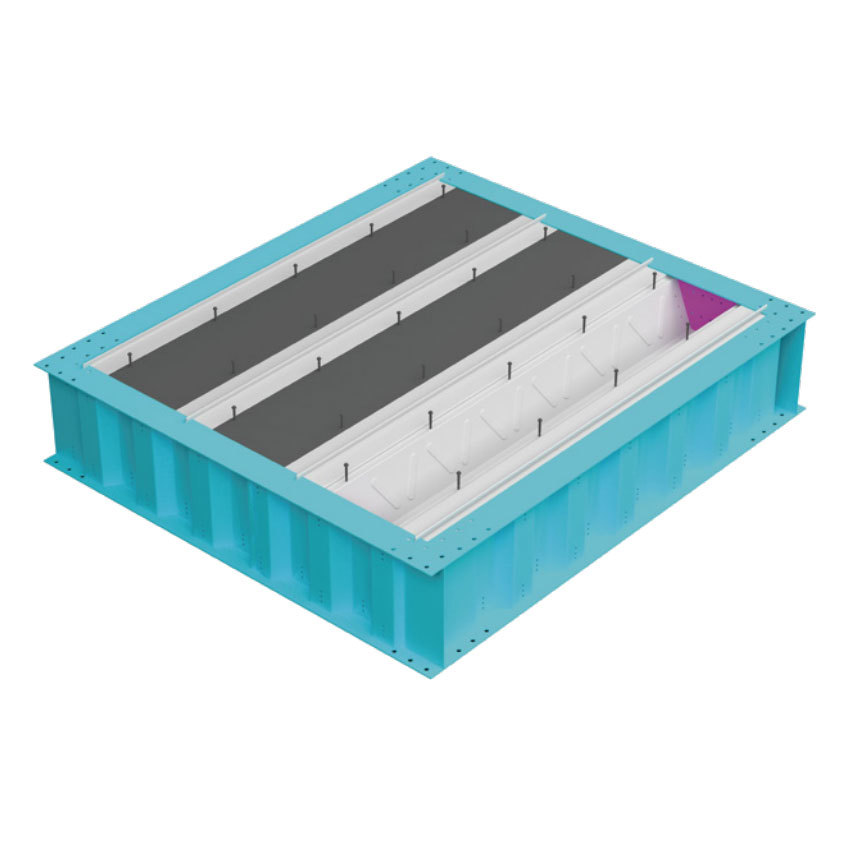

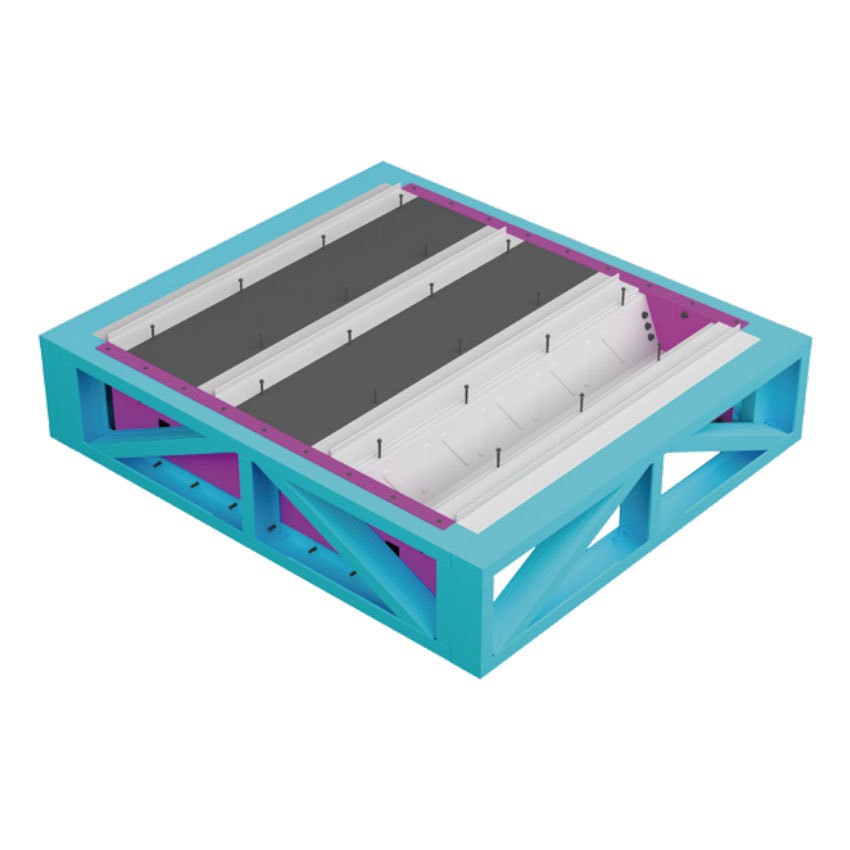

1. Integrated beam and slab configuration

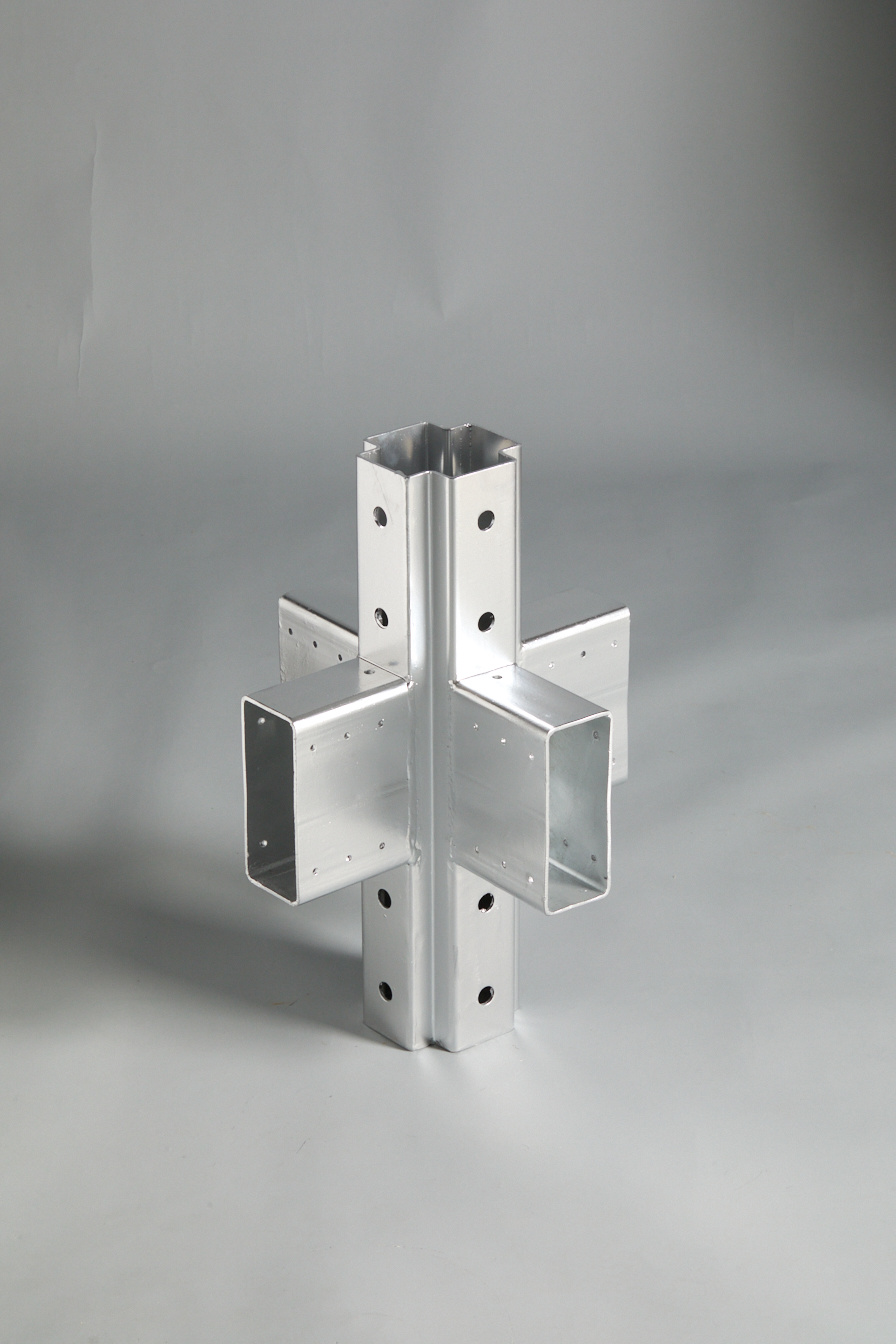

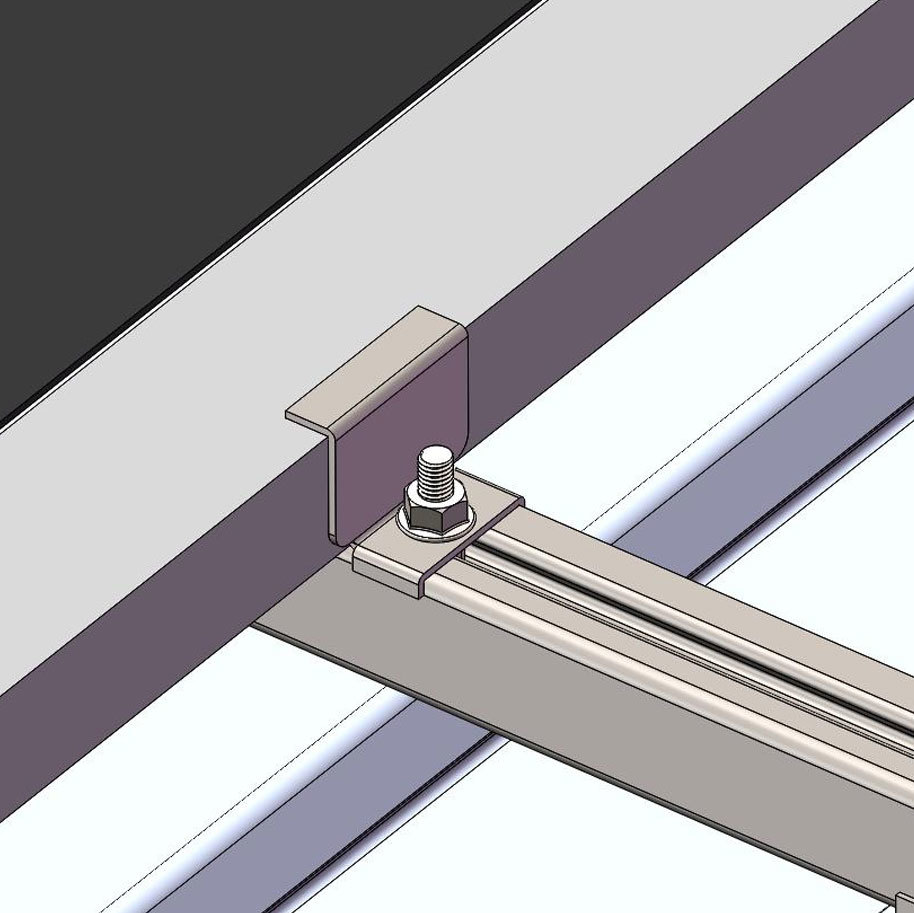

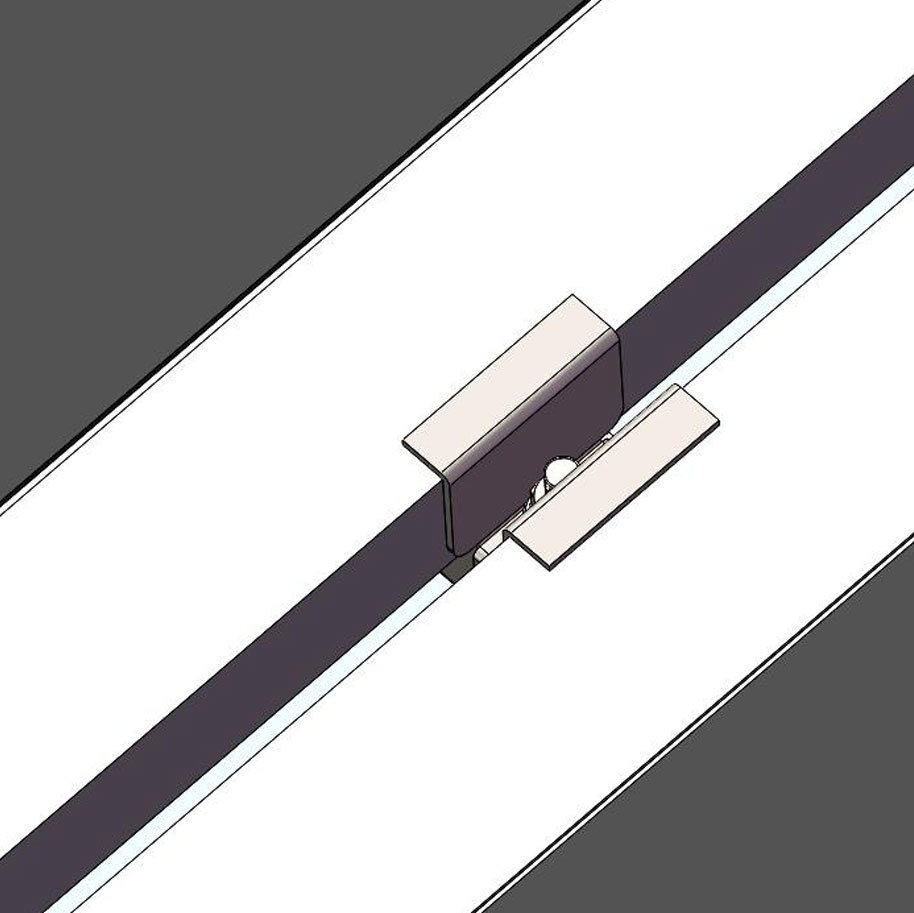

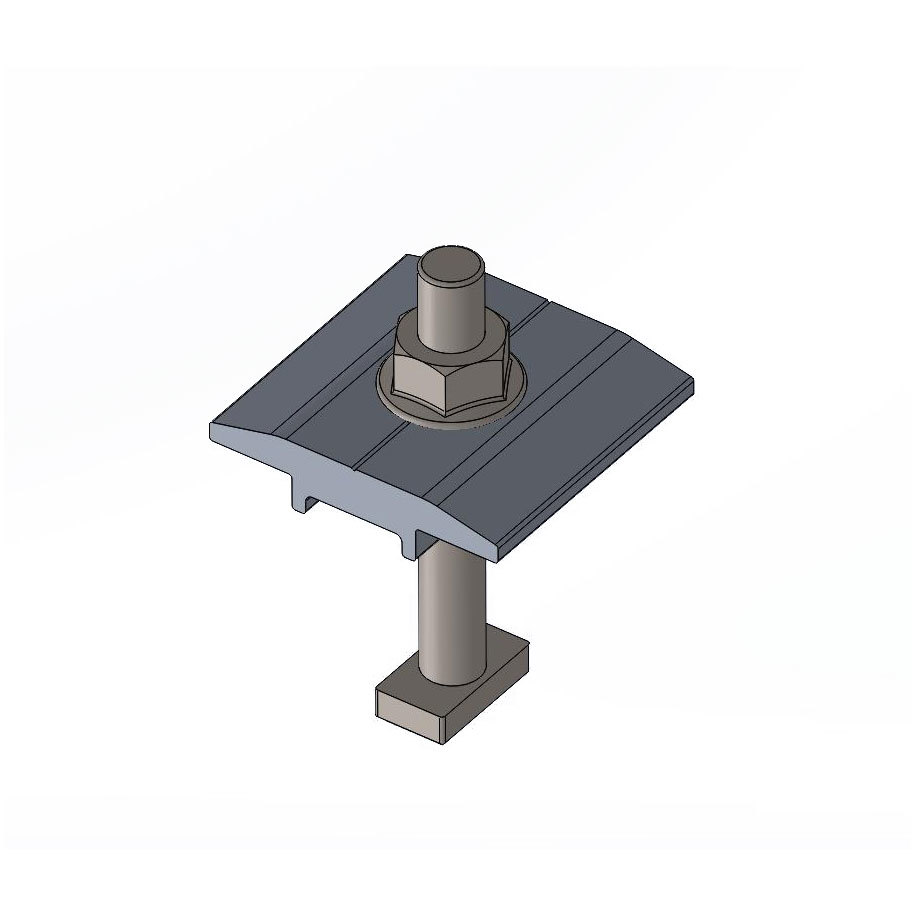

The V-shaped floor beam is combined with compressed steel plate and cement fiber board through structural optimization, combining the floor beam and floor panel to jointly bear the floor load. It is not only a beam but also a plate, forming a combination of beam and plate, with a simple structure.

2. Excellent mechanical properties

The V-shaped floor beam combines the advantages of steel and concrete materials through geometric configuration, and after mechanical optimization, its bearing capacity and durability fully meet the requirements of the specifications. Before decoration, a certain thickness of cement fiber board, silicon calcium board, and other boards are locked on the bottom of the V-shaped floor beam as a whole. The V-shaped floor beam can also play a bidirectional load guiding effect.

3. Short construction period

The V-shaped floor beam eliminates the need for formwork support and removal during the construction of cast-in-place concrete floors, thus accelerating the construction progress of the project. In addition, after the V-shaped floor beam is laid, it can be directly poured with concrete or used as a work platform for other trades. Each floor can be constructed simultaneously, and proper construction organization can significantly shorten the construction period. This approach is particularly suitable for prefabricated steel structures, greatly improving construction efficiency.

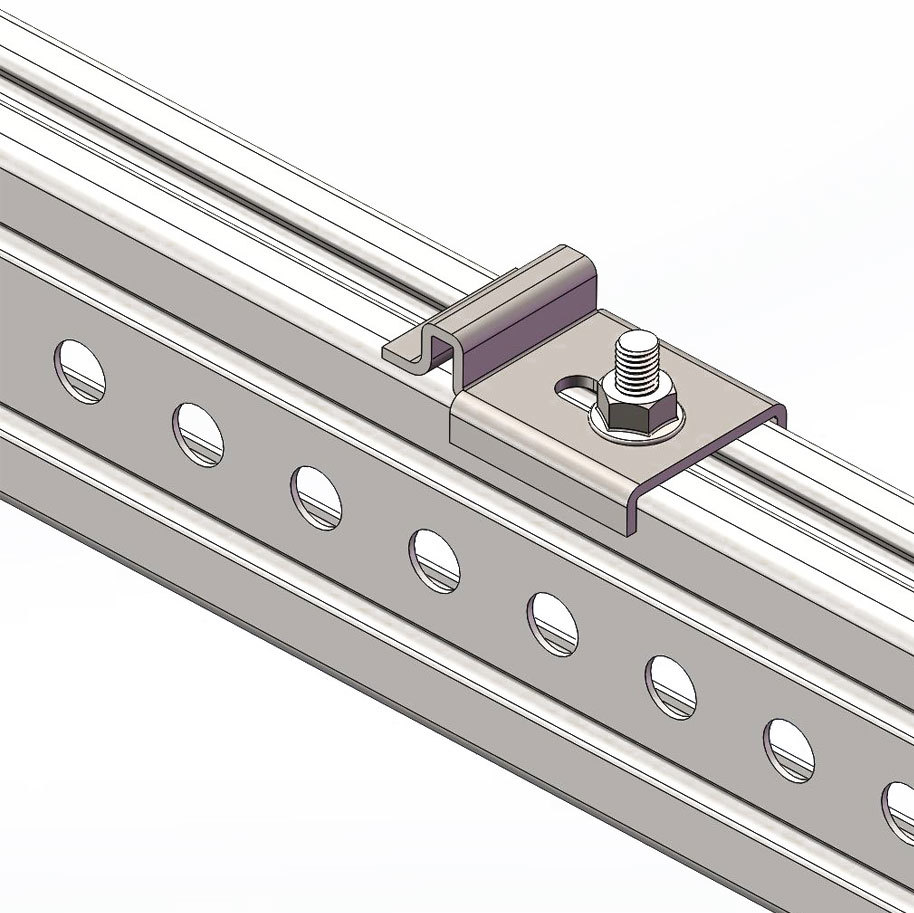

4. High space utilization rate

The ribs and grooves of V-shaped floor beams can be used to arrange various pipelines, and line pipe holes can be reserved according to needs. The reserved aperture can reach 70mm under normal conditions. The combination of beam and slab configuration makes V-shaped floor beams have high bearing capacity and stiffness, and the advantage of building clearance is outstanding under the same floor height conditions.

5. Low material consumption

Under the same load-bearing capacity, the V-shaped floor beam is one-third of the weight of the cast-in-place concrete floor slab, with light self weight and low material consumption.

6. Good ecological performance

Compared with traditional cast-in-place concrete floor slabs, V-shaped floor beams can fully achieve dry operation without the need for a formwork system, saving a lot of wooden formwork, and have good ecological performance in terms of labor, materials, and working environment.

7. Convenient structural adjustment

The V-shaped floor beam can meet the applicability requirements by flexibly adjusting the thickness and even geometric configuration according to the floor load, span, and usage environment. It has strong structural adaptability, convenient production and processing, and broad usage conditions.

Product Inquiry

HaoHeng Group

Address: Room 1808, Block A, Vanke Cloud City, Jiemei District, Xiamen City, Fujian Province

Business cooperation:

Copyright © HaoHeng (FuJian) Building Materials Technology Co, Ltd. All rights reserved