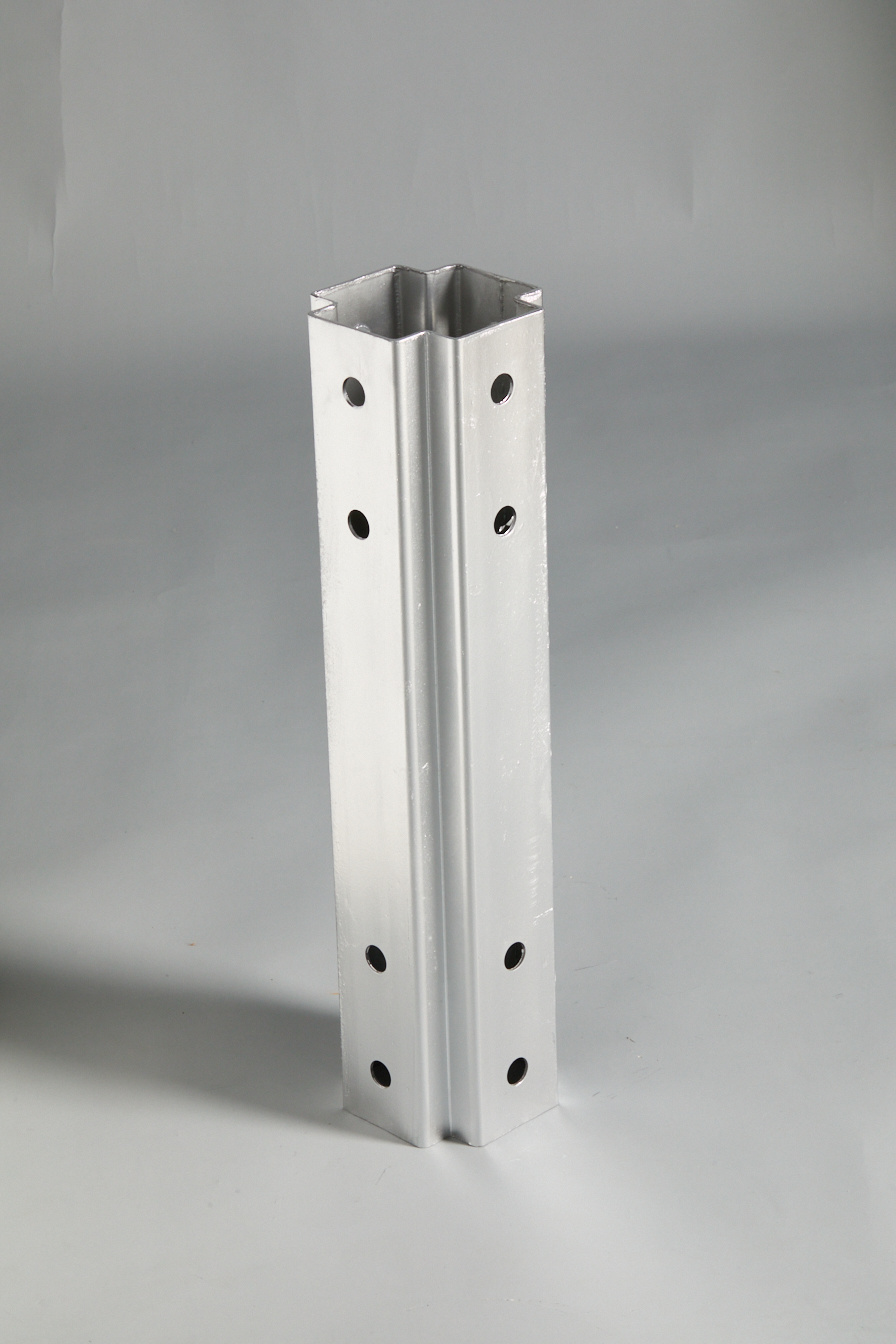

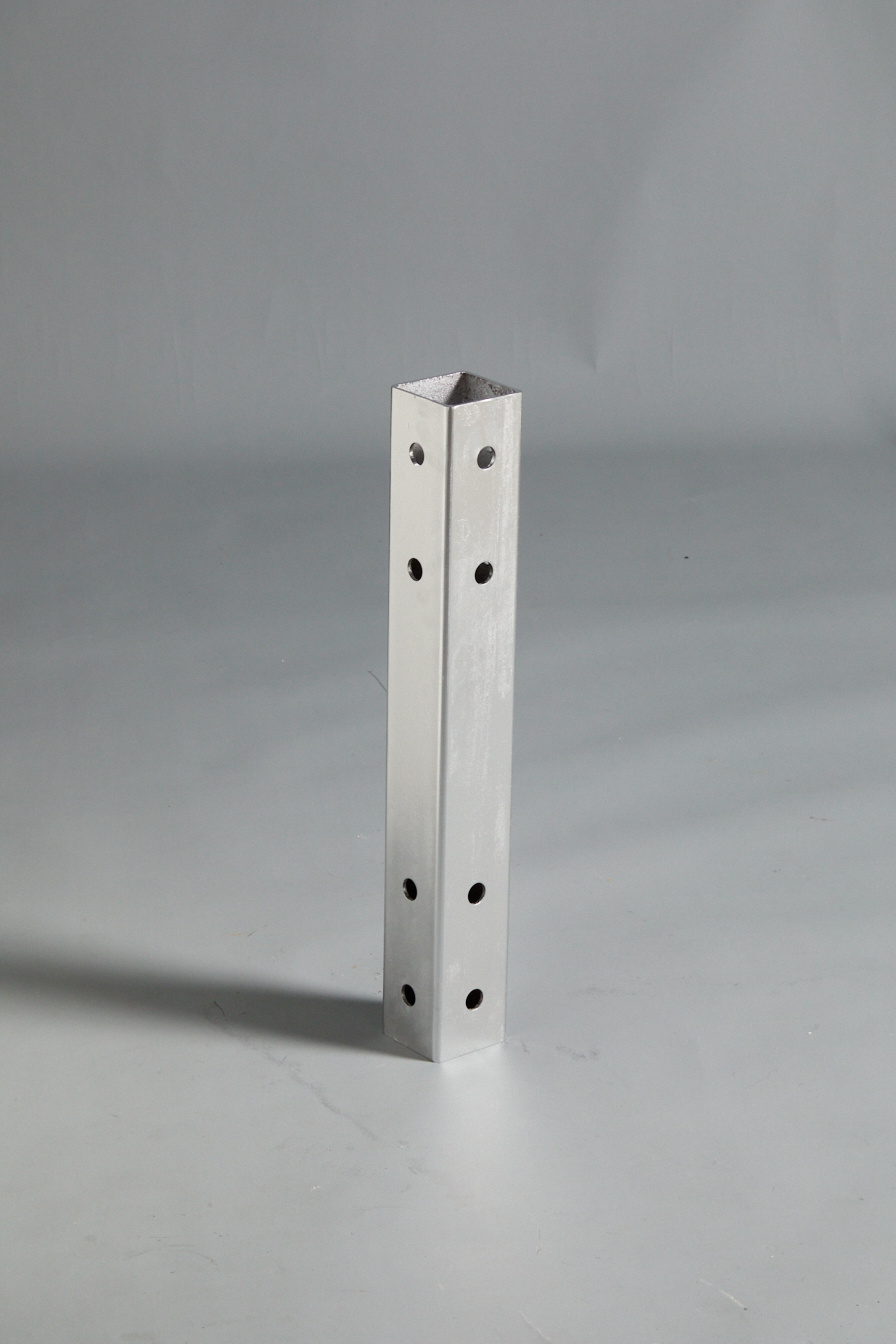

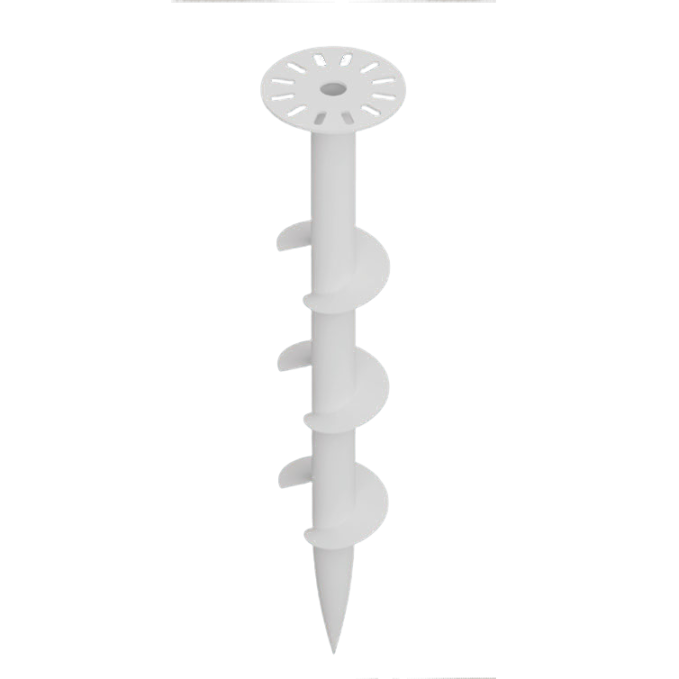

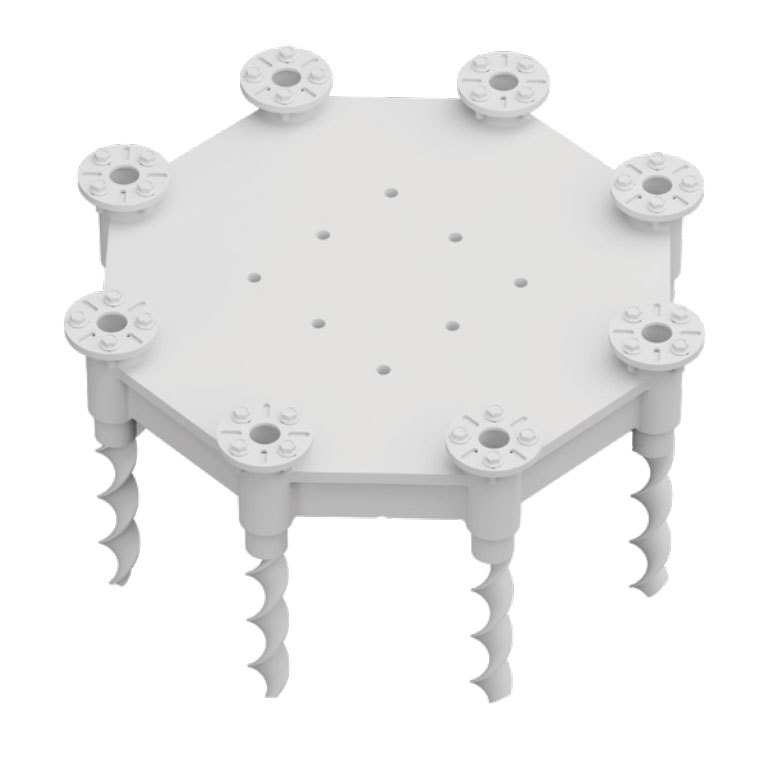

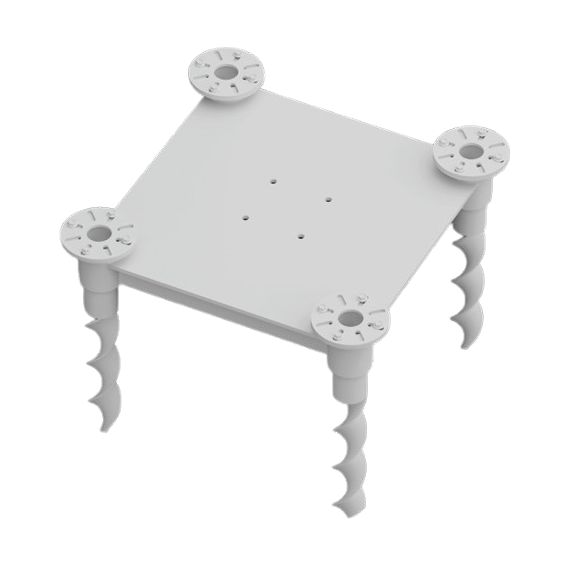

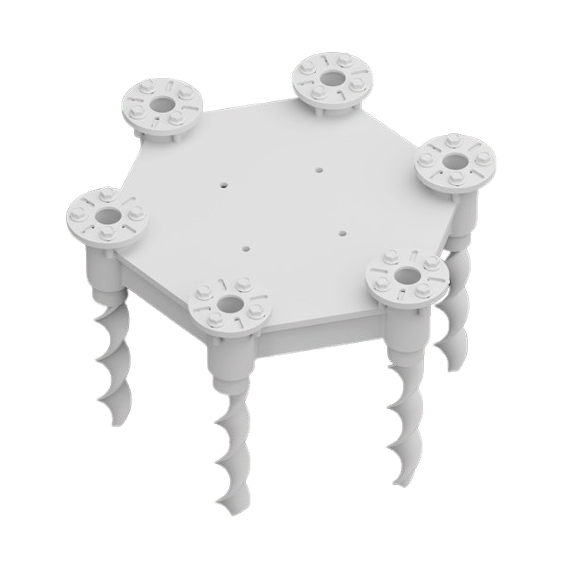

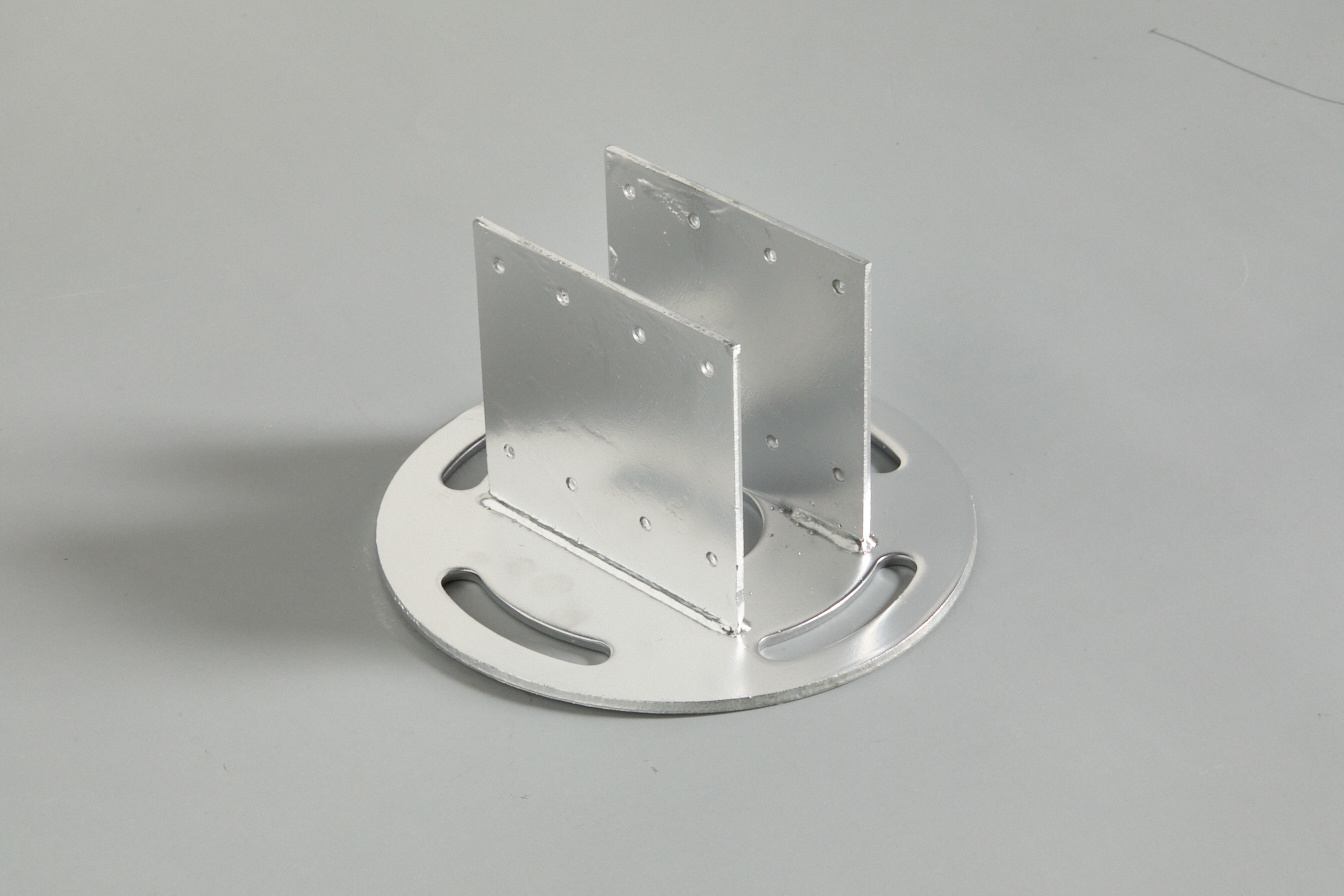

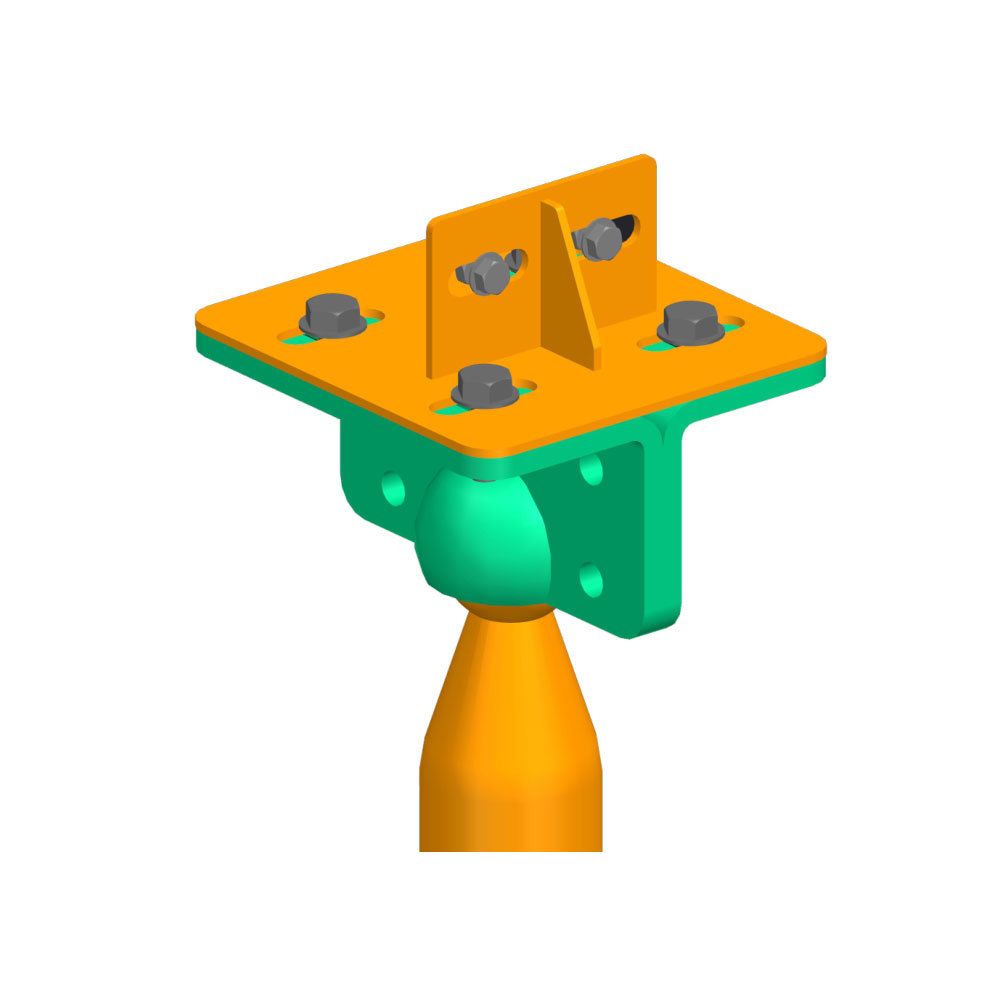

Double-Helix Screw Pile | Patented Foundation Solution

Classification:

Product Details

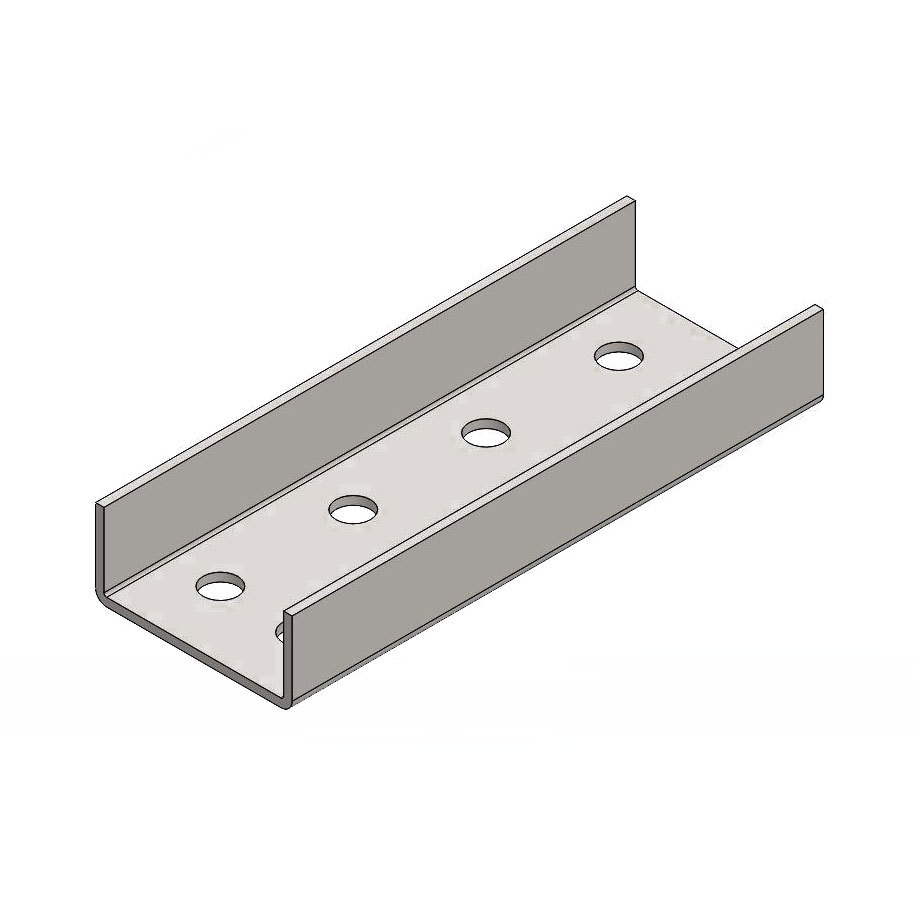

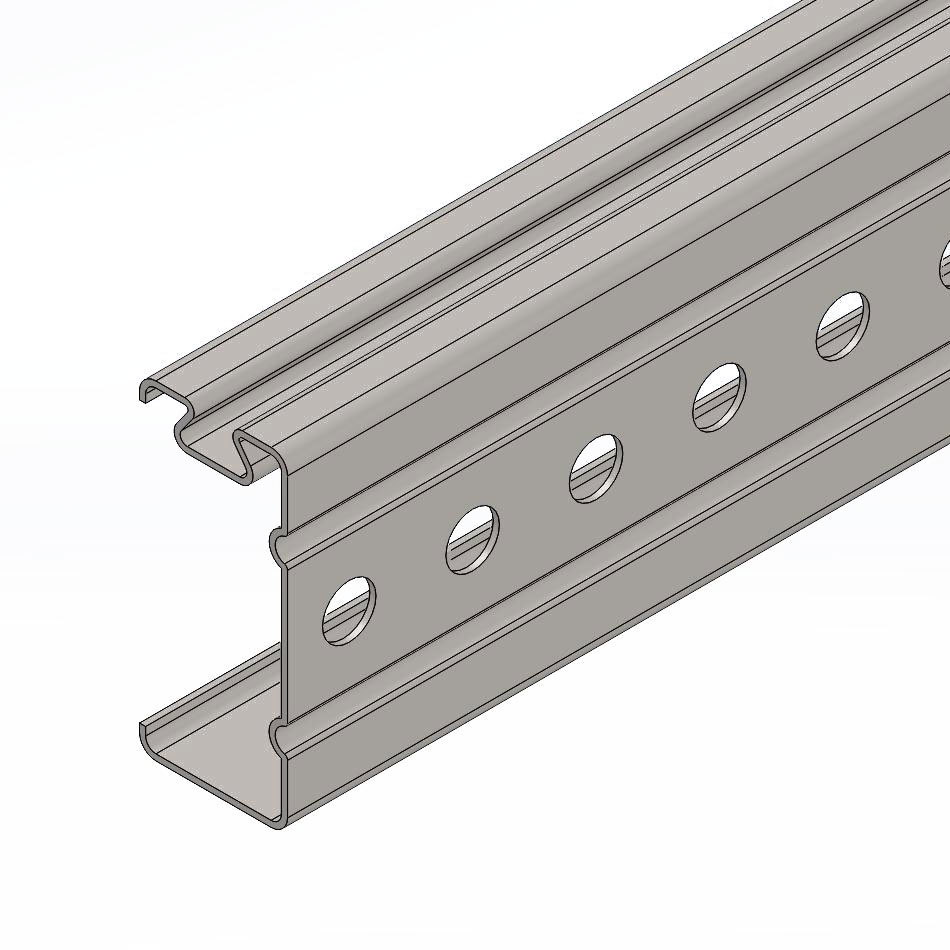

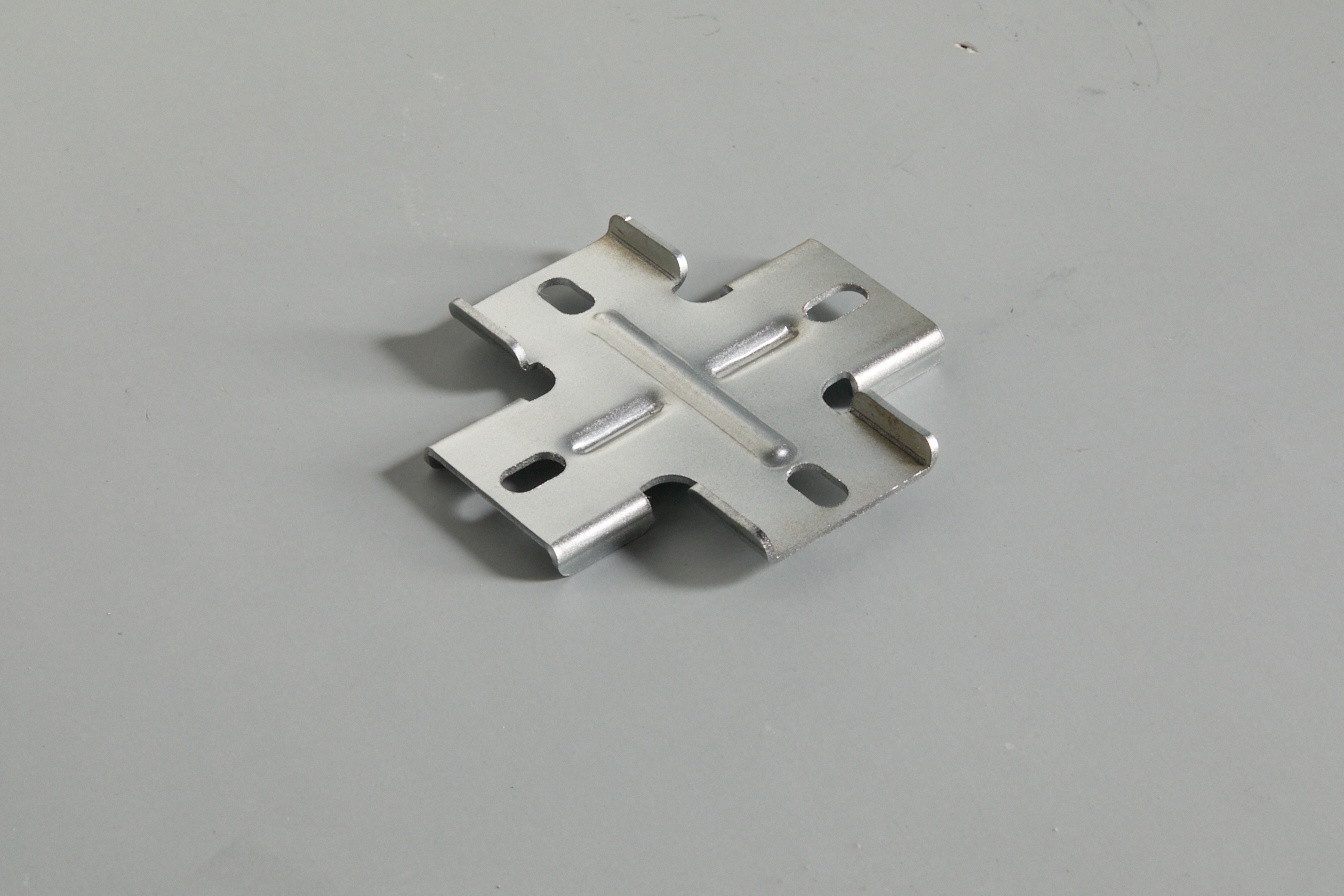

Technical Specifications & Material Quality

-

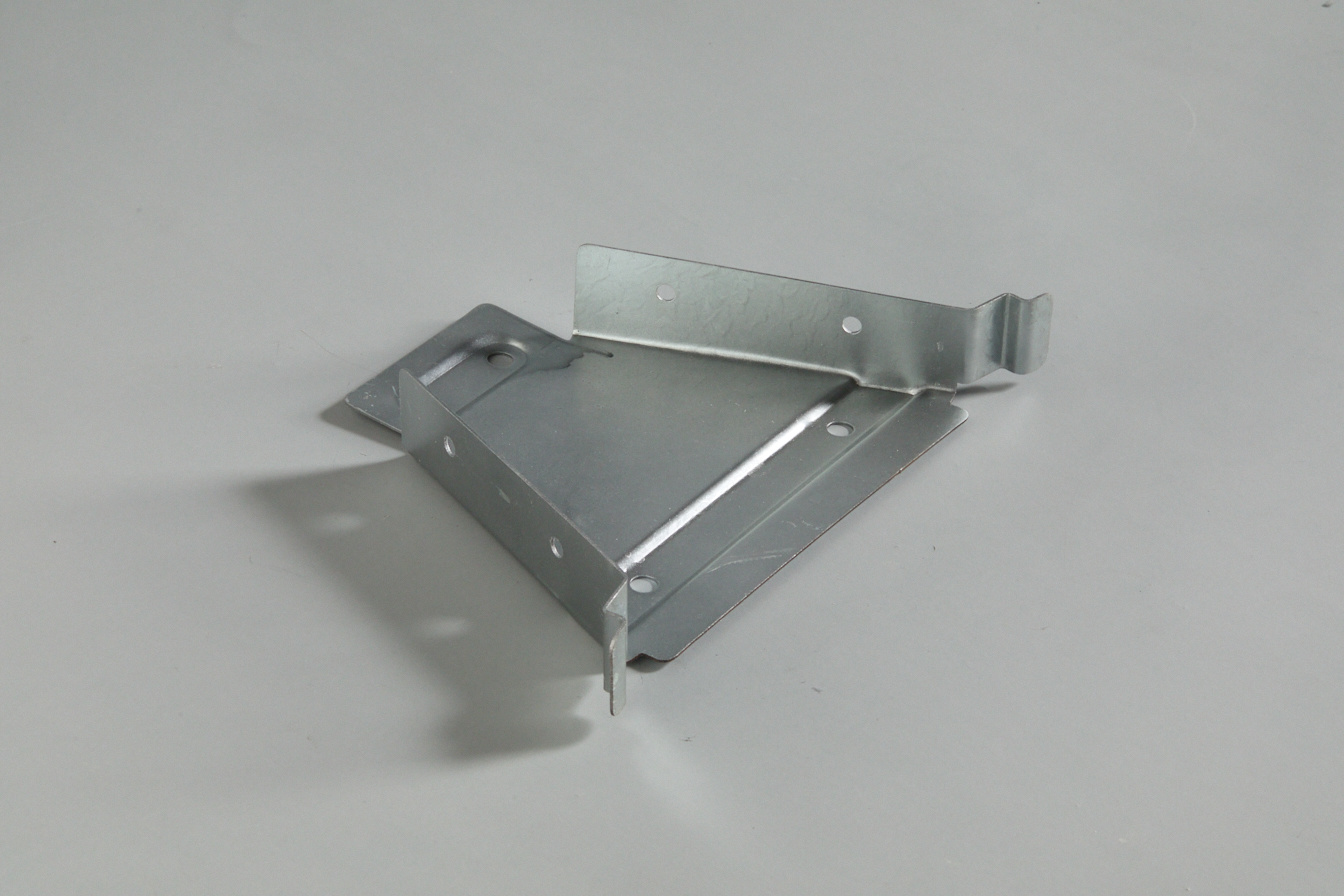

Material: Manufactured from high-strength, hot-dip galvanized steel, compliant with Q235B and Q355B grades for superior corrosion resistance and structural integrity.

-

Available Specifications: Fully customizable in diameter and length to meet your project's geotechnical requirements.

-

Common Sizes: Ø140mm, Ø165mm

-

Other Sizes: Ø245mm, Ø273mm, Ø325mm, Ø377mm, Ø426mm

-

-

Design Flexibility: The diameter and length are selected based on single-pile bearing capacity and ultimate foundation load requirements.

Our Installation & Quality

Our standardized screw pile construction process ensures precision, efficiency, and verified performance for every project.

1. Layout & Positioning

The exact location of each helical pile is accurately marked on the ground according to the approved civil engineering and architectural design drawings.

2. Installation & Driving

A suitable pile driving machine or head is selected to rotate the screw pile into the ground at the designated angle and to the required depth.

3. Load Verification & Testing

The load bearing capacity of each pile is verified through static load or pull-out tests to ensure it meets or exceeds the design standards and foundation requirements.

Key Advantages & Applications

Why Choose Our Patented Screw Piles?

-

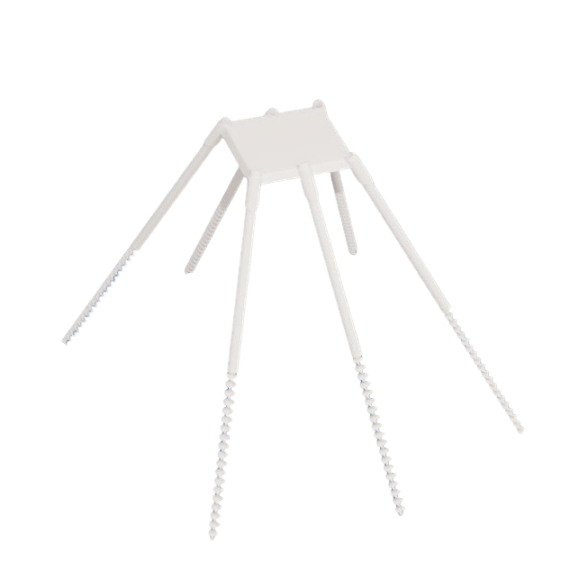

Optimal for Poor Soil Conditions: Specifically engineered for challenging sites like beach swamps and other weak, low-bearing soils.

-

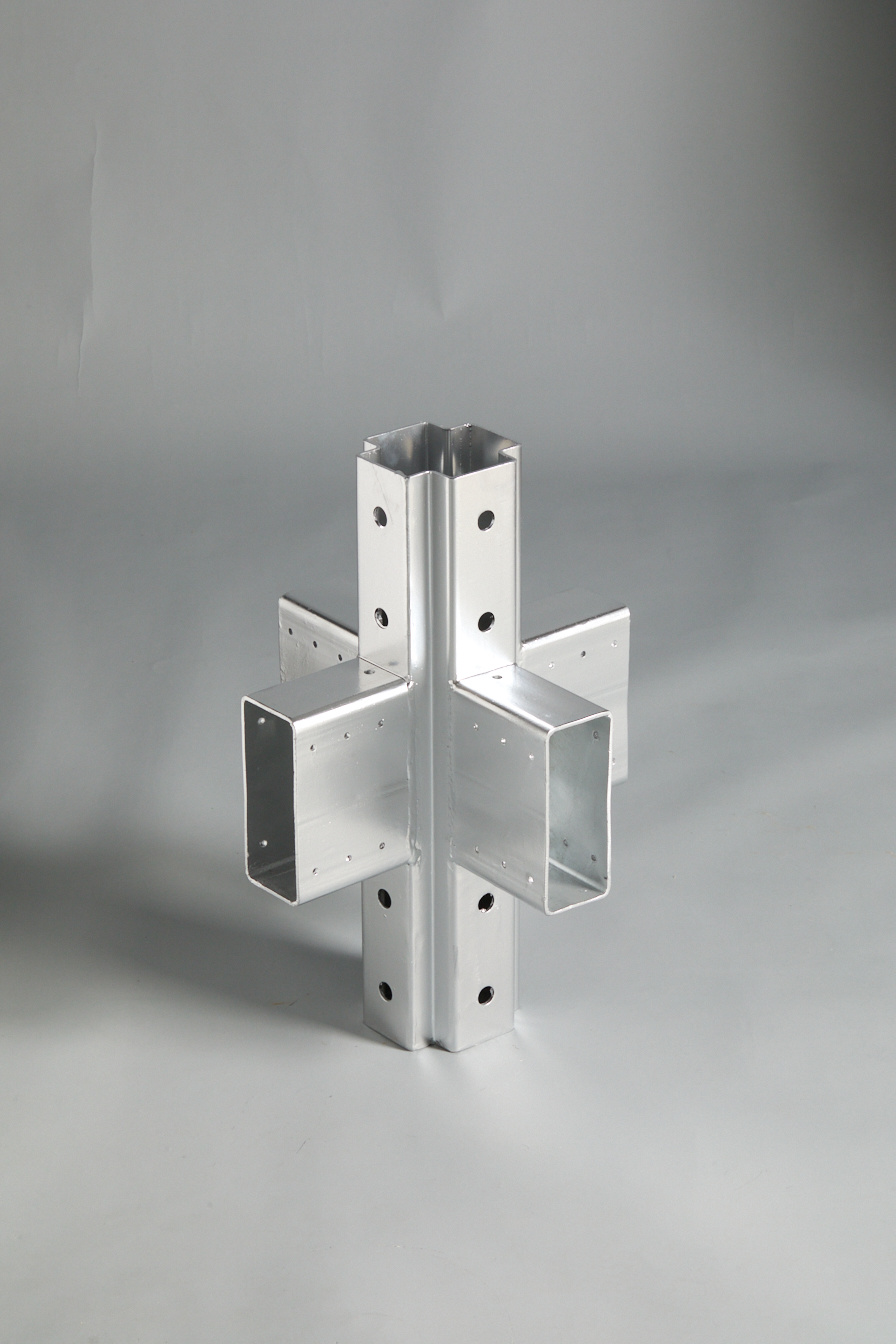

Maximum Load Capacity: The grouted body creates a much larger effective diameter, providing an unparalleled steel foundation for steel frame structures and steel houses.

-

Proven Factory Quality: As the patent-holding manufacturer, we guarantee strict quality control from raw material to finished product.

-

Ideal for Prefabricated Workflows: Enables fast, efficient screw pile construction, perfectly suiting the timeline of Prefabricated and modular builds.

Primary Applications in Civil Engineering & Construction:

-

Foundation systems for steel houses, steel structure warehouses, and steel frame buildings.

-

Critical infrastructure projects requiring reliable Ground Anchor and deep foundation solutions.

-

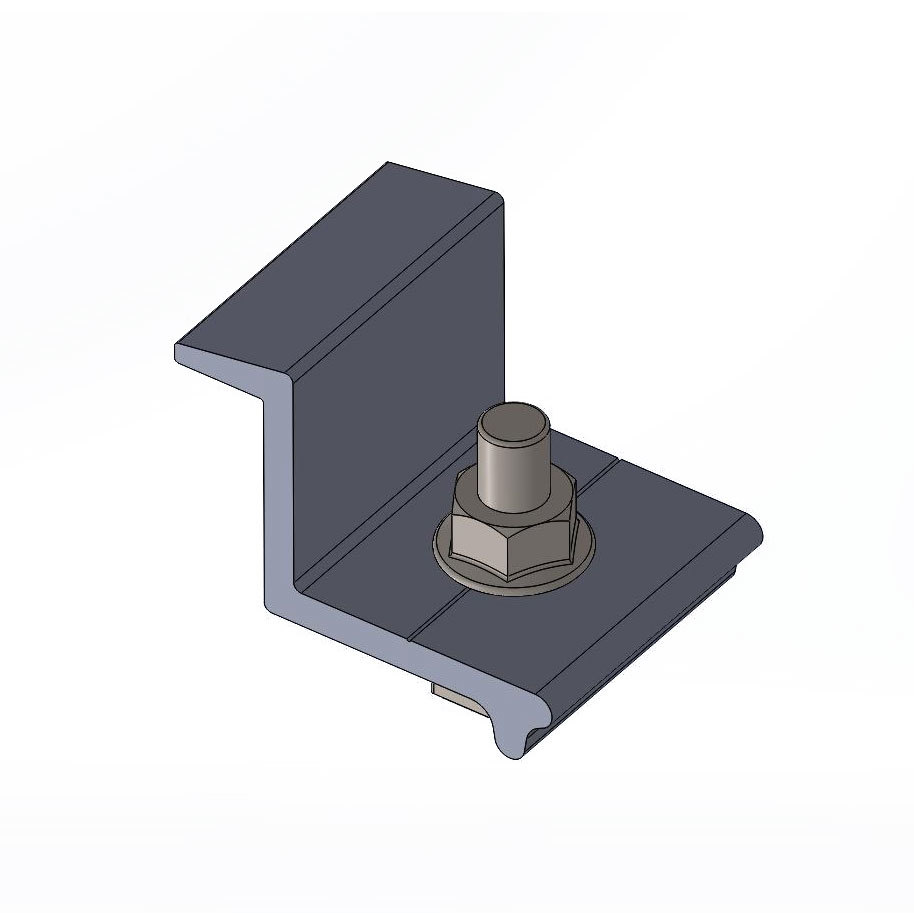

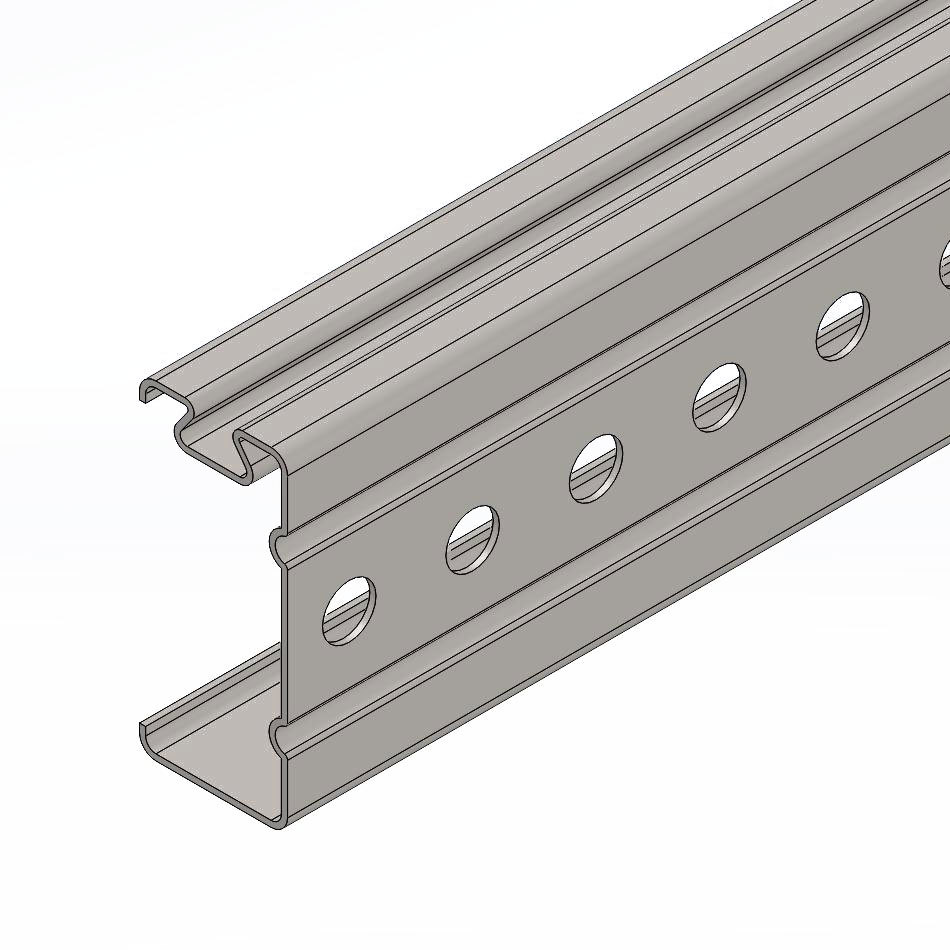

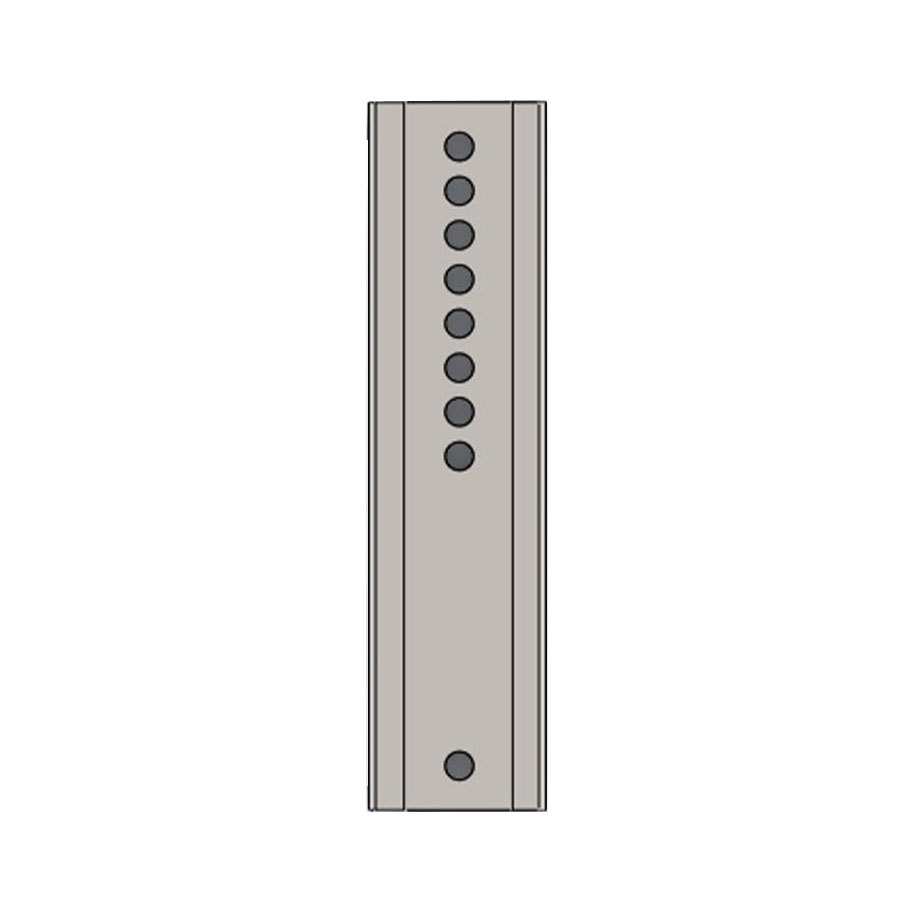

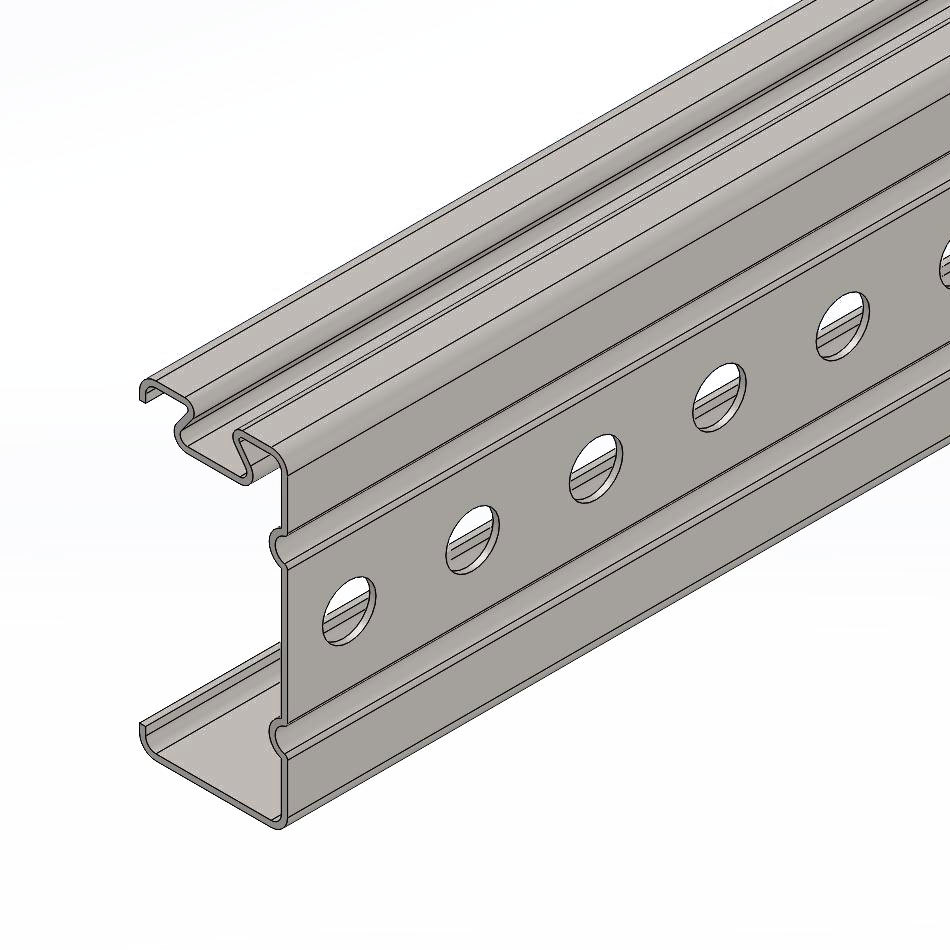

Solar panel mounting systems, retaining walls, and other civil engineering applications.

-

The go-to foundation for all Prefabricated structural projects.

Application Scenarios in Action

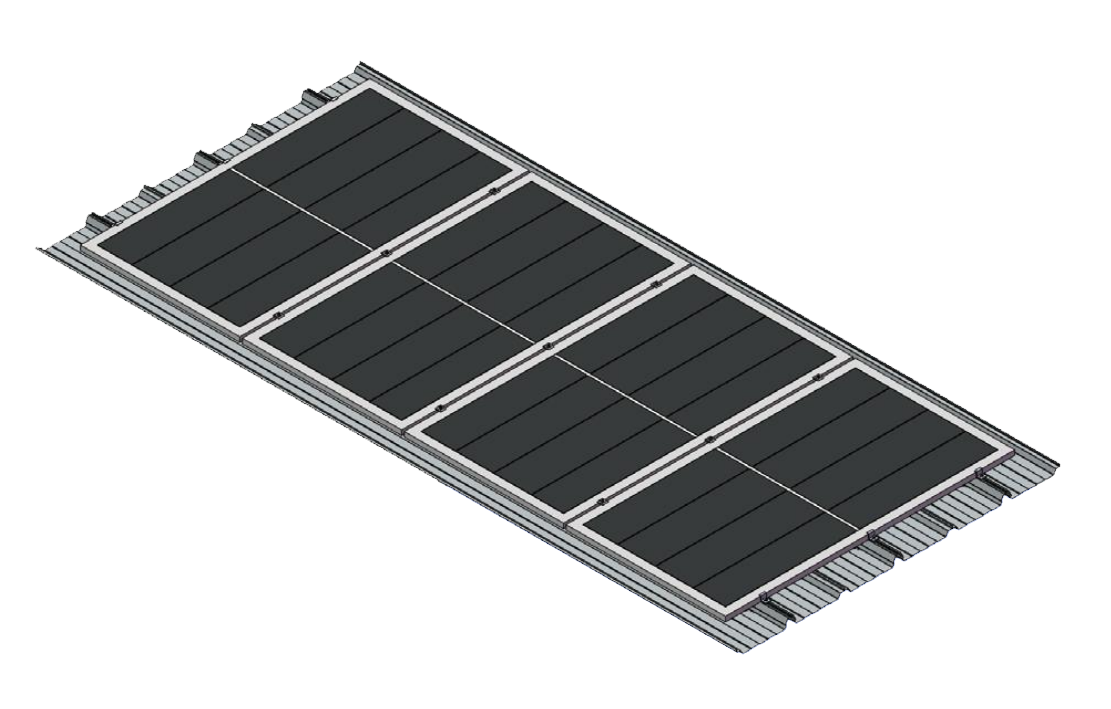

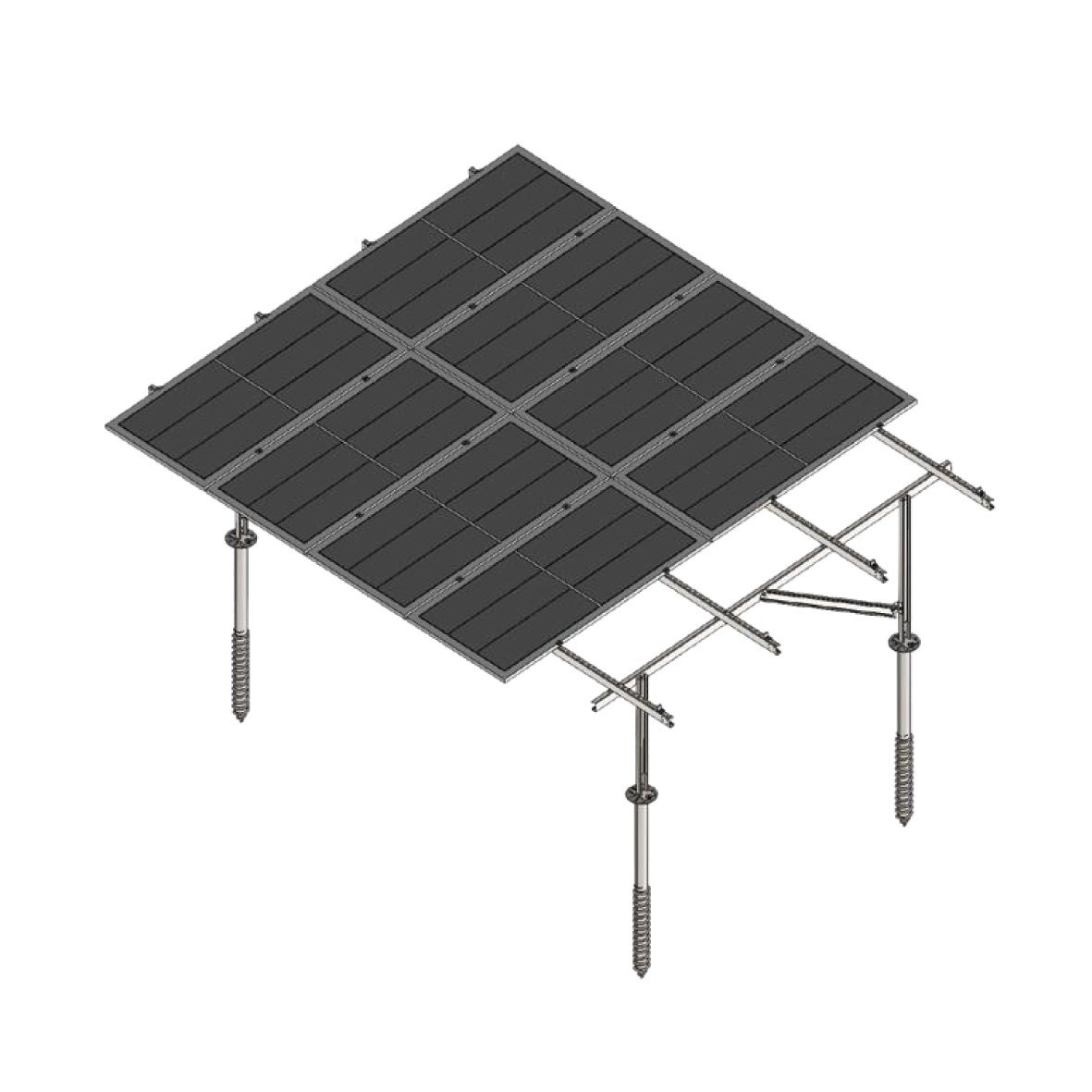

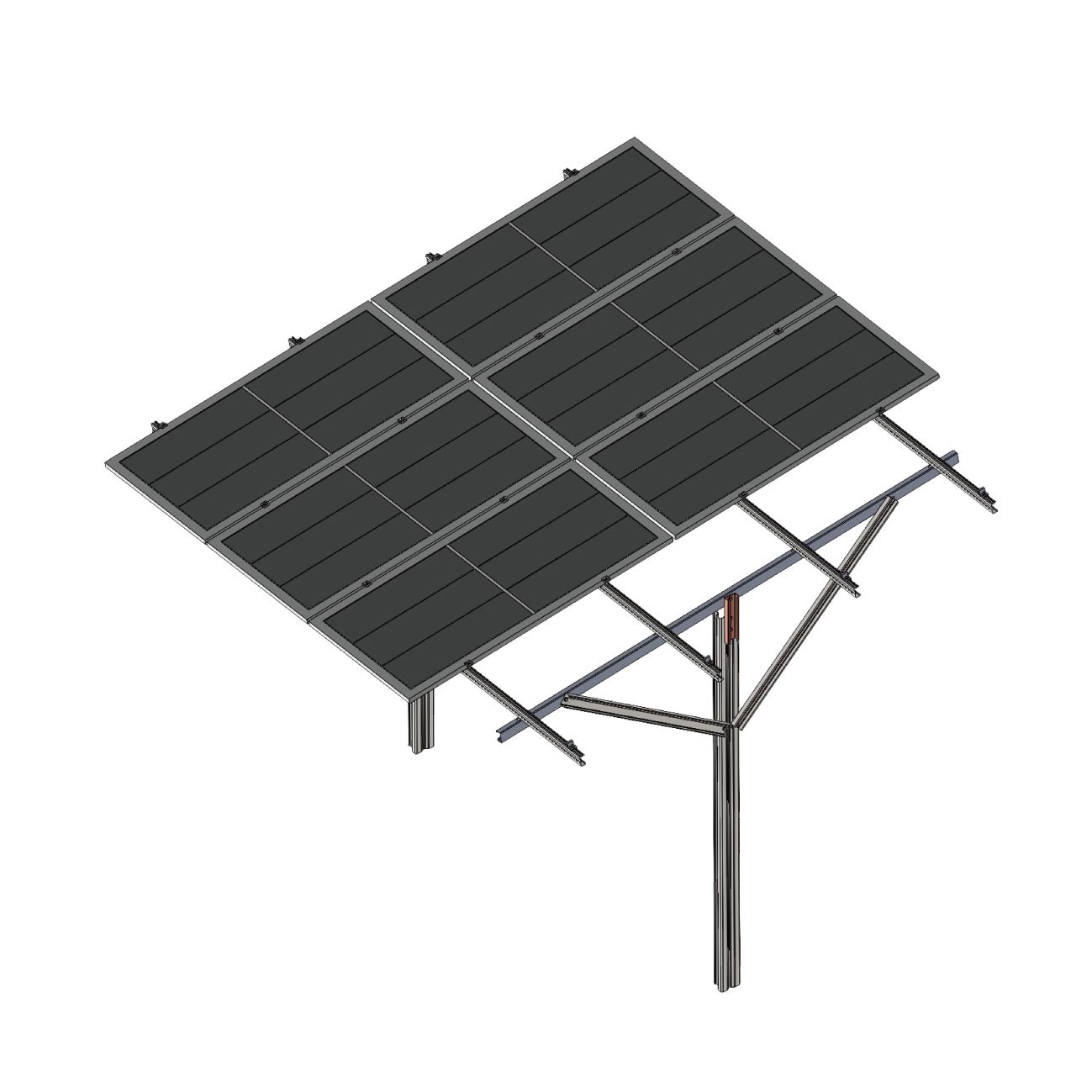

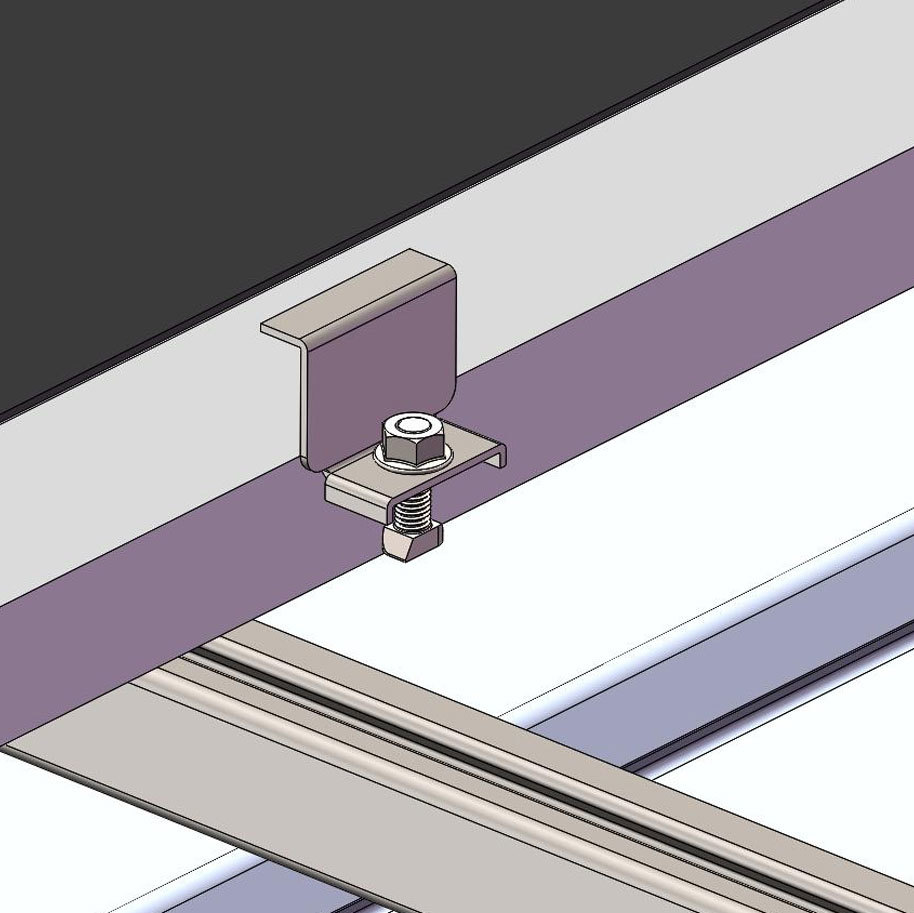

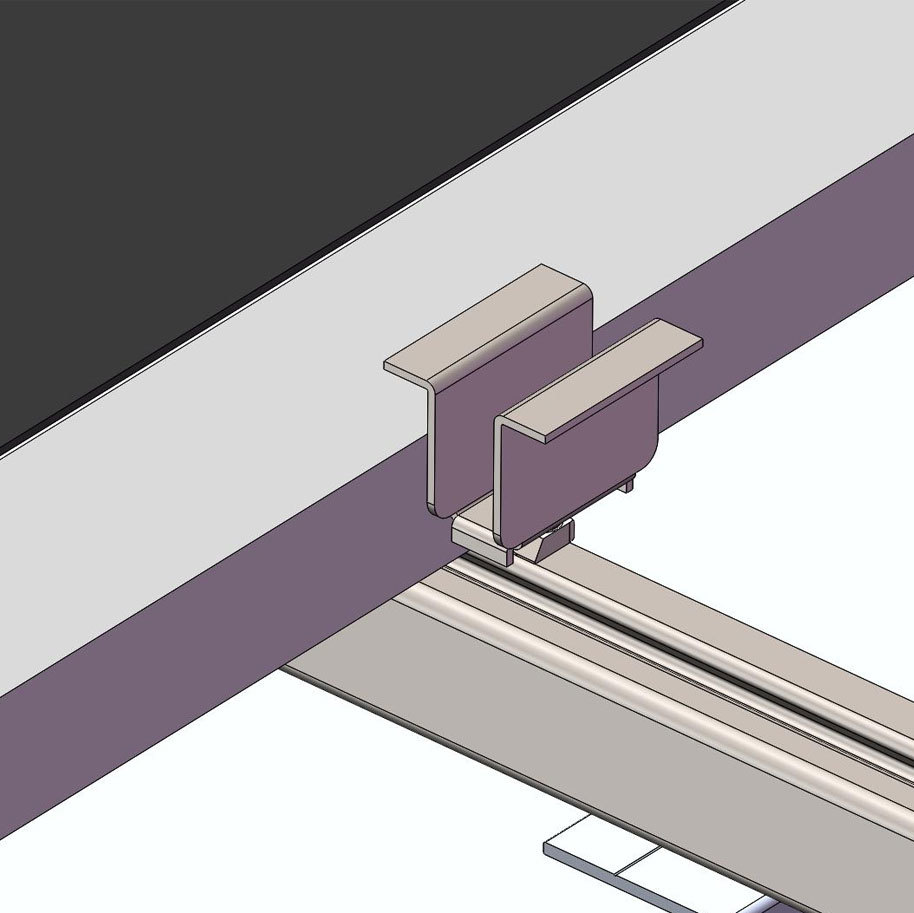

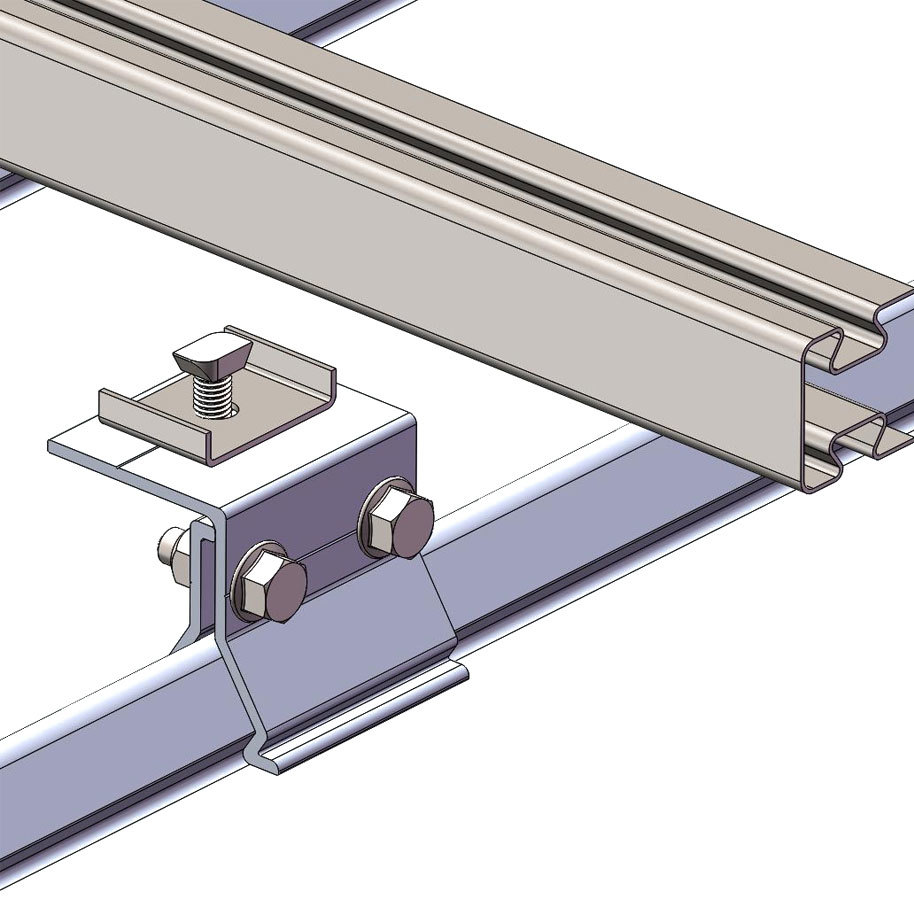

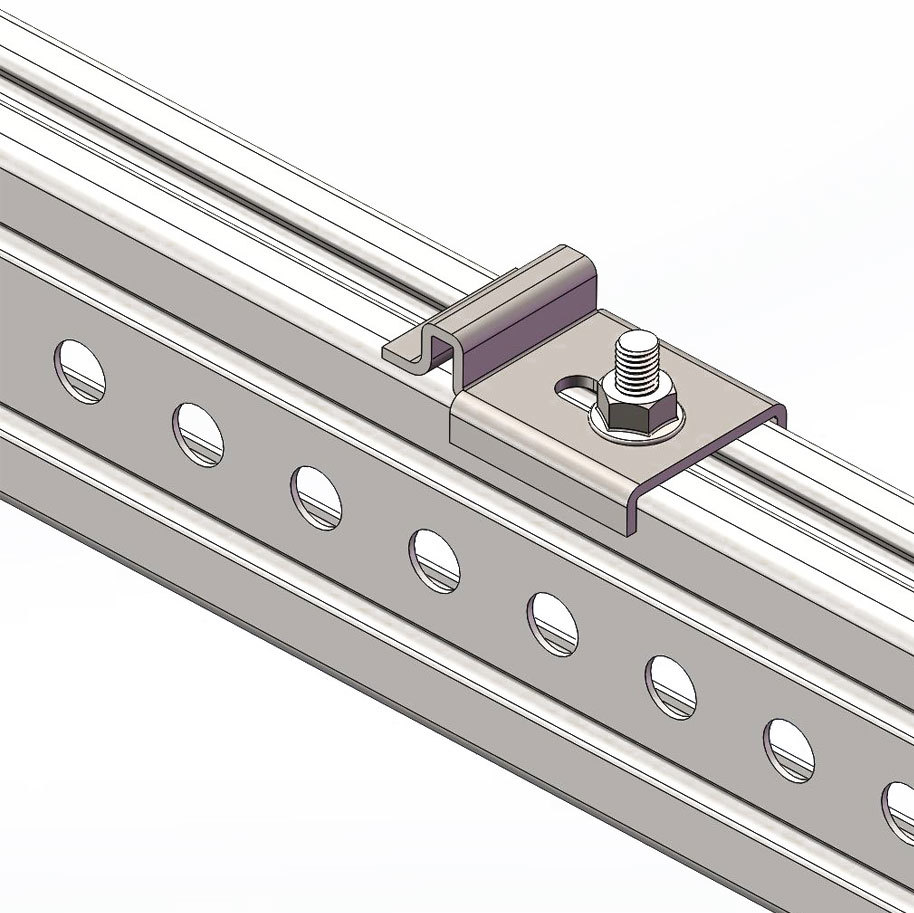

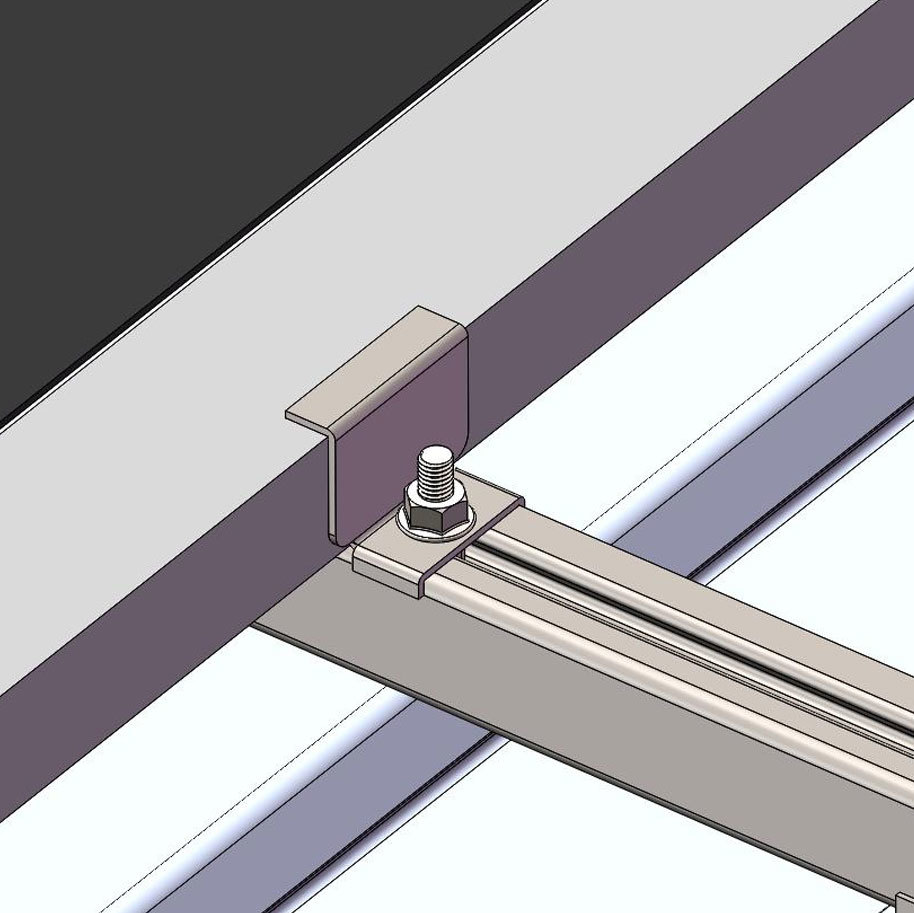

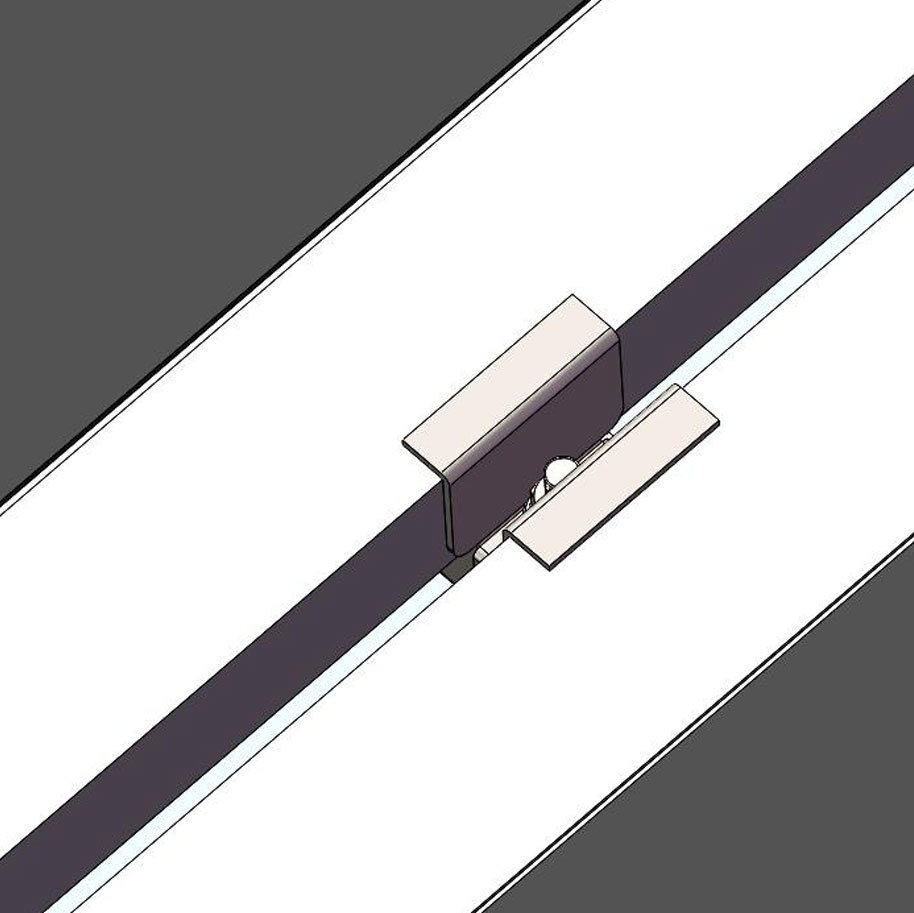

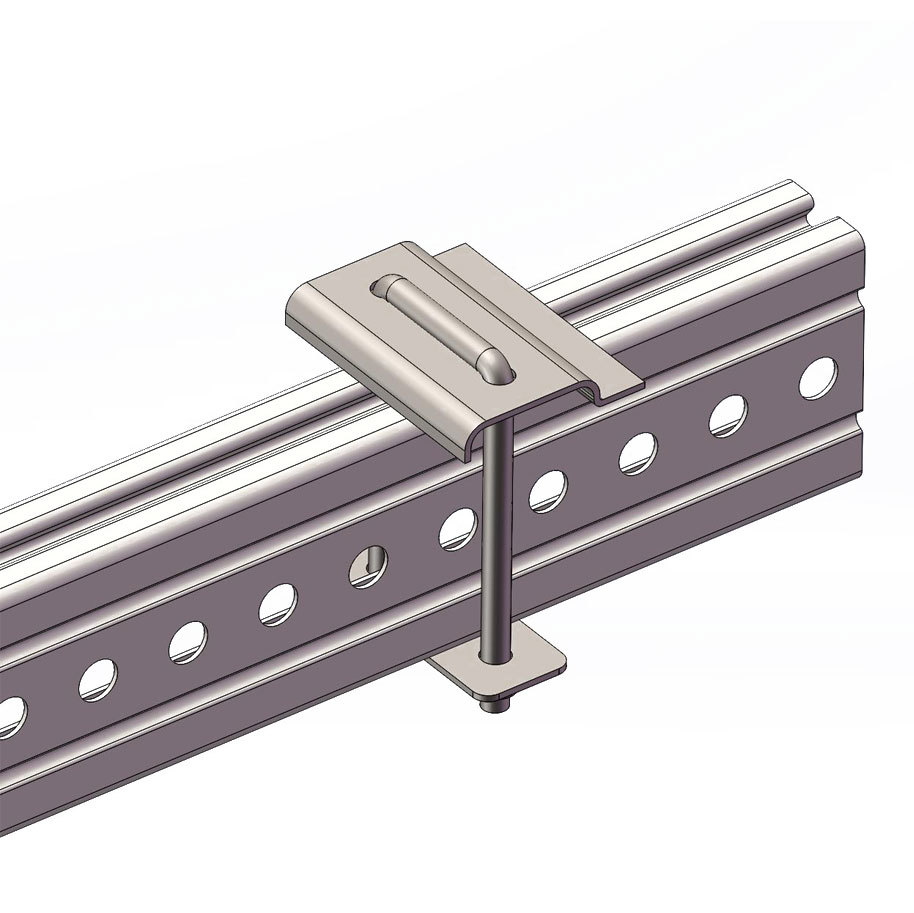

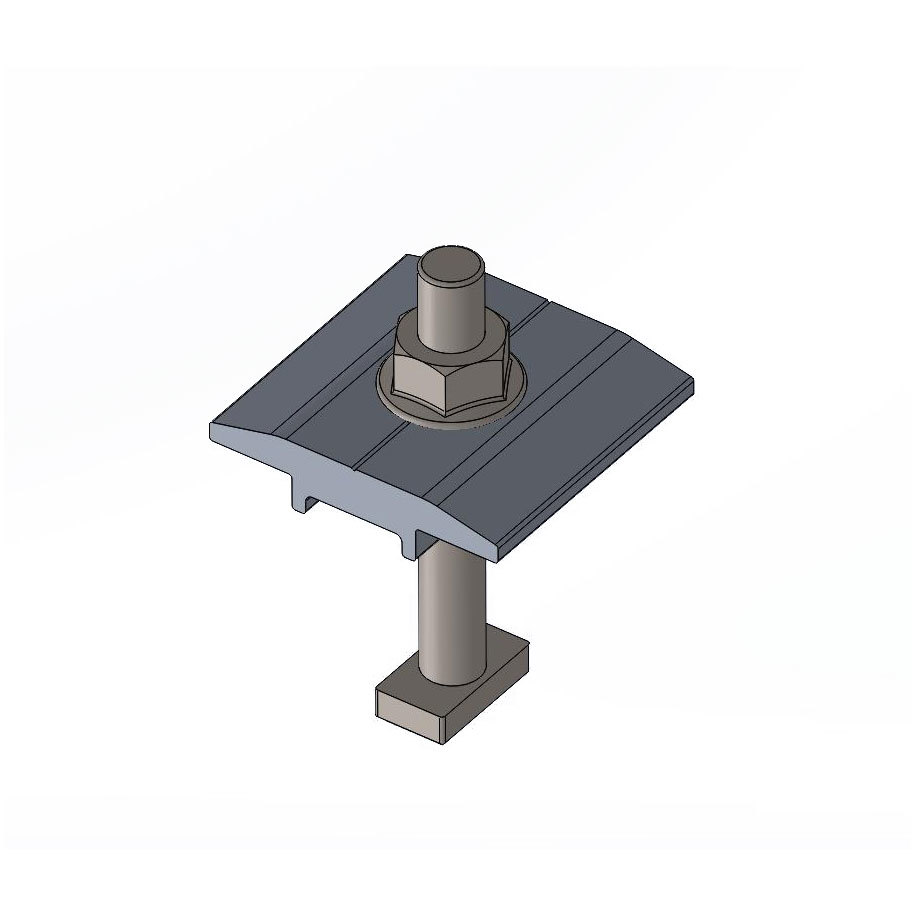

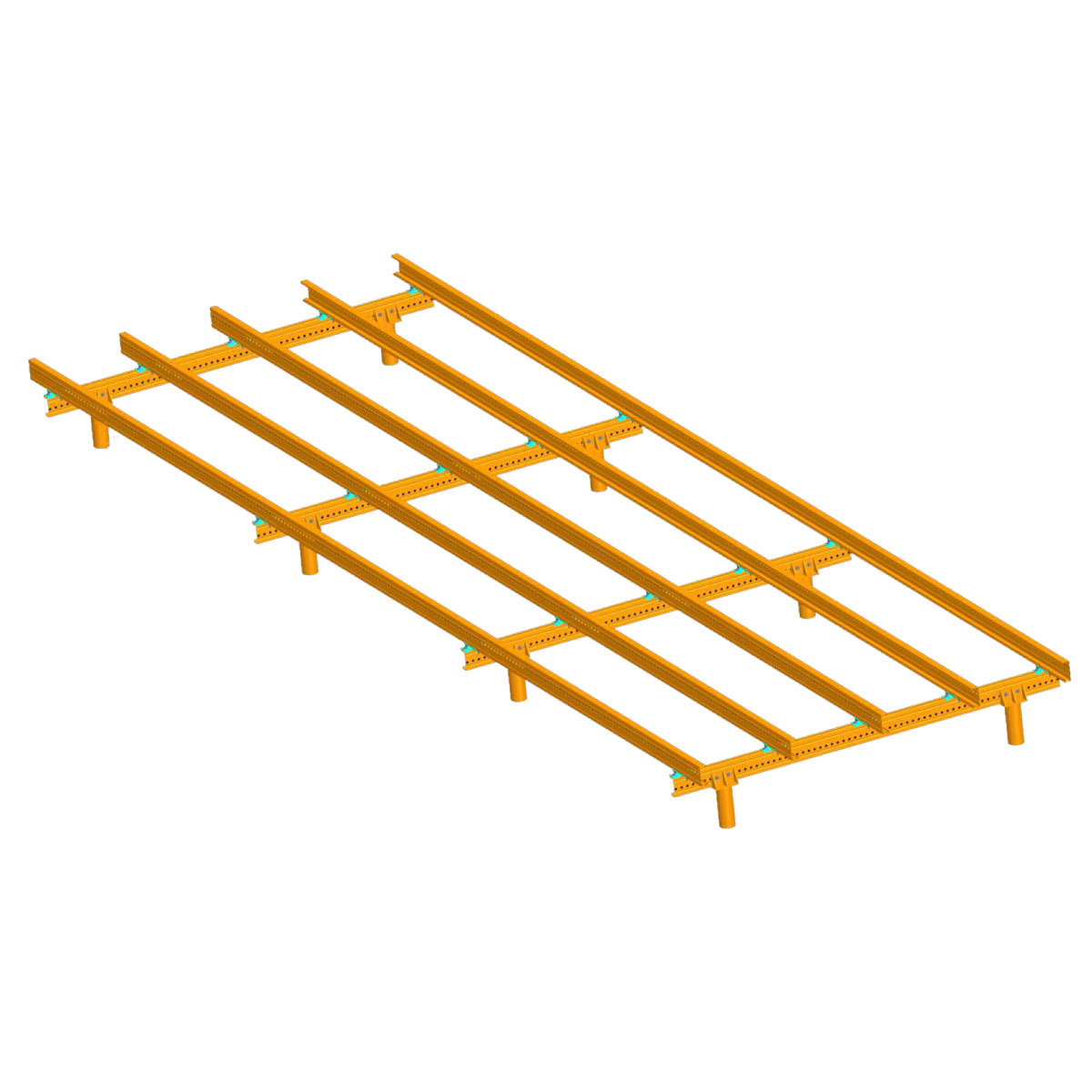

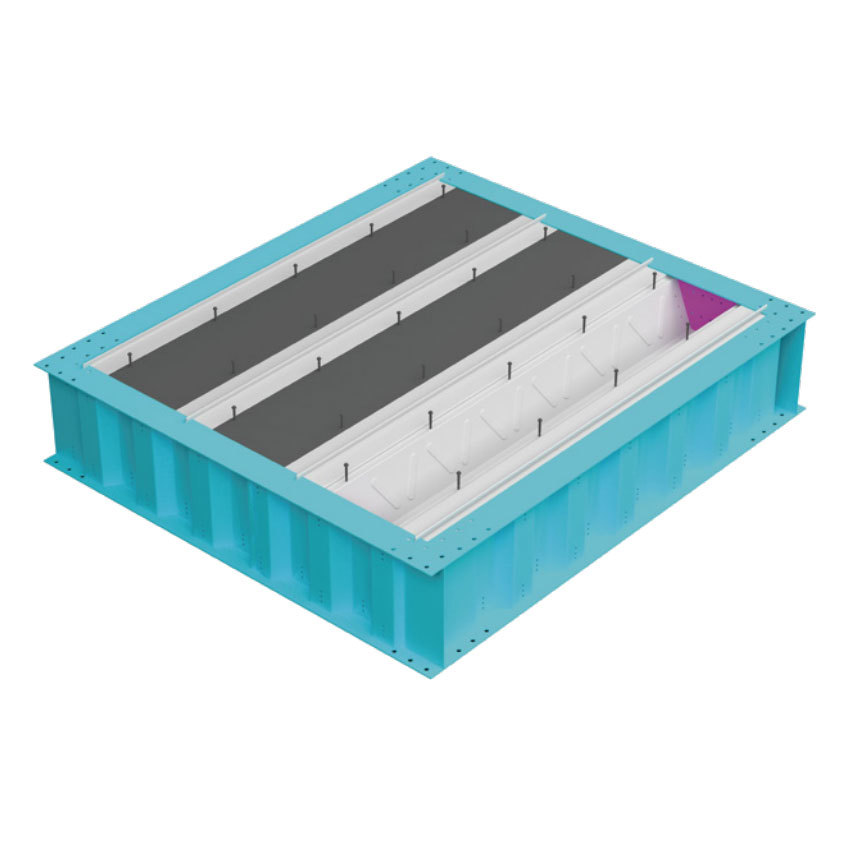

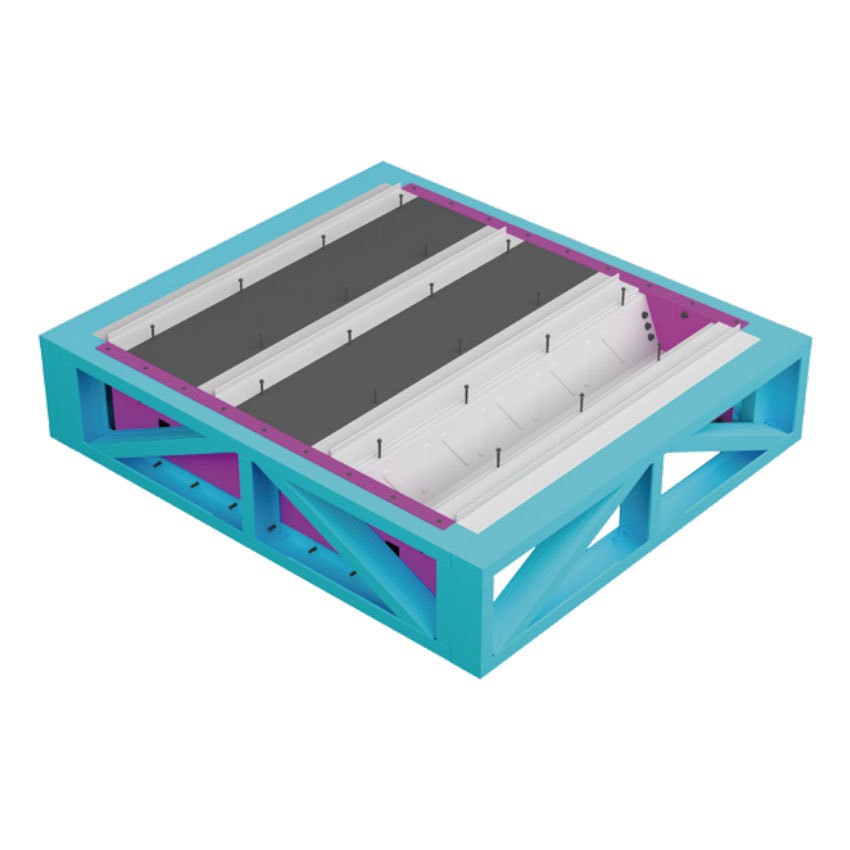

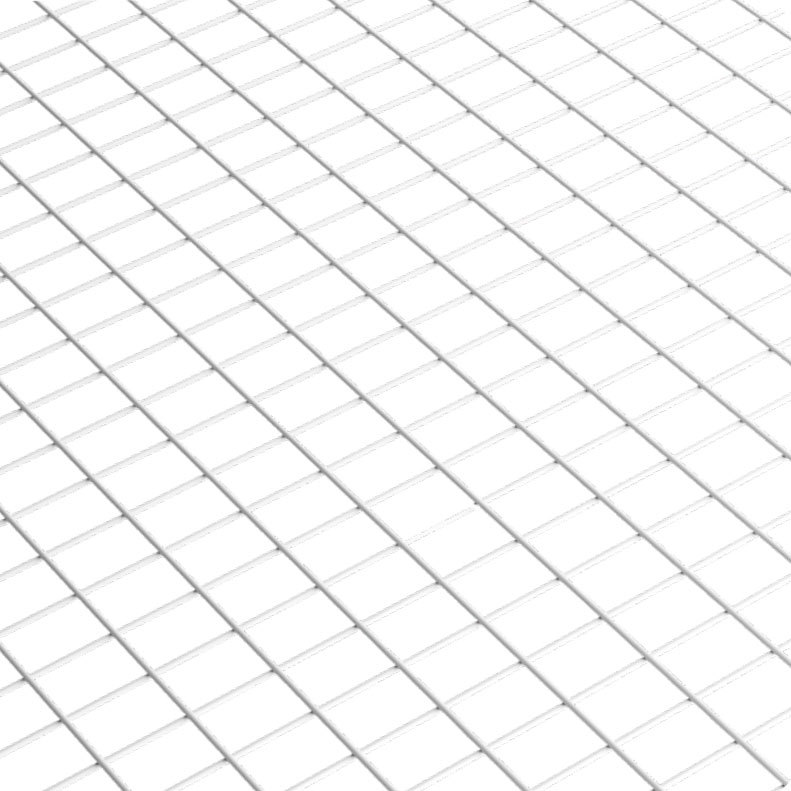

1. Solar Farm Foundations: A Robust & Rapid Solution

Our helical piles provide the perfect foundation for solar panel mounting systems. The fast, minimal-impact screw pile construction eliminates the need for extensive concrete work, significantly accelerating project timelines. The high tensile capacity also makes them ideal for ballasted systems in civil engineering projects.

2. Steel Structure : The Ideal Steel Foundation

For prefabricated steel structure warehouses and steel frame buildings, our screw piles offer unparalleled stability. The grouted composite pile ensures maximum load-bearing capacity, creating a rock-solid foundation that withstands heavy machinery and dynamic loads for decades.

3. Coastal & Challenging Sites: Engineering for Stability

Specifically engineered for weak soils, our screw piles excel in beachfront and swampy conditions where traditional foundations fail. They act as a deep Ground Anchor, providing the necessary stability for steel houses and other structures in these demanding environments.

Screw Pile Q&A: Your Questions Answered

Q: What are the main advantages of screw piles over traditional concrete foundations?

A: Screw piles (helical piles) offer a modern, efficient alternative. Key advantages include:

-

Speed & Efficiency: Our process requires no digging or curing time. As the graphic shows, you move directly from installation to building, drastically reducing project timelines compared to the multiple steps of concrete work.

-

Minimal Site Impact: The installation process is clean with minimal excavation, preserving the site and reducing environmental disturbance.

-

Immediate Load-Bearing: There is no waiting period; the piles can bear load immediately after installation, accelerating your steel structure construction schedule.

-

Cost-Effectiveness: Savings on labor, equipment time, and materials make screw pile construction a highly competitive foundation solution.

Q: How do I know if screw piles are suitable for my project's soil conditions?

A: To provide you with a precise and engineered solution, we require a geotechnical investigation report from your construction site. Alternatively, you can provide us with high-definition photos of the soil profile on site. Our engineering team will analyze the soil data and perform the necessary calculations to determine the suitability and recommend the optimal helical pile configuration for your specific project, ensuring a reliable and cost-effective steel foundation.

Q: How much faster is screw pile installation compared to pouring concrete?

A: Significantly faster. A screw pile foundation can typically be installed in a single day for a standard project, eliminating the need for the multi-step, multi-day process of concrete foundation work (excavation, forming, pouring, and curing). This speed is especially beneficial for prefabricated builds, keeping the entire project on a fast track.

Q: Are screw piles more expensive than concrete foundations?

A: While material costs can be comparable, the total installed cost of screw piles is often lower. The significant reductions in labor, heavy machinery time, and project duration lead to overall savings. Furthermore, the long-term reliability and minimal risk of settlement provide excellent value, making them a smart economic choice for civil engineering and commercial projects.

Q: Can screw piles be used for both new construction and retrofitting existing structures?

A: Absolutely. Helical piles are ideal for new steel frame buildings and steel houses. They are also perfectly suited for underpinning and stabilizing existing structures that have settled or require additional foundation support, serving as an effective ground anchor.

Q: What is the load capacity of your screw piles, and how is it verified?

A: The load capacity varies by pile size and soil. Our helical piles are engineered for high load capacity, and we verify this through on-site static load tests or pull-out tests. This rigorous quality assurance ensures every pile meets the design standards for your civil engineering project.

Q: Why choose your company as my screw pile manufacturer and supplier?

A: As the patented factory, we control quality from raw material to finished product. We are not just a screw piles supplier; we are experts in screw pile construction and civil engineering, offering direct technical support from the architectural design phase through to installation, ensuring you get the best foundation solution.

Q: Are your screw piles galvanized, and why is that important?

A: Yes, all our screw piles are manufactured from hot-dip galvanized steel. This process provides a thick, durable zinc coating that offers superior corrosion resistance, ensuring the long-term structural integrity and longevity of your foundation, even in corrosive environments.

Q: Can screw piles be used for all types of soil and projects?

A: Helical piles are exceptionally versatile and perform well in a wide range of conditions where traditional concrete foundations struggle, including weak, sandy, or saturated soils. They are the ideal foundation for steel houses, warehouses, solar farms, and as a ground anchor in challenging environments.

Have more questions?

Please contact our customer service team or email us directly for further assistance.

Your Trusted Partner in Foundation Solutions

Our expertise in civil engineering and screw pile construction ensures you get a technically sound and cost-effective foundation. We support your project from the architectural design phase through to on-site installation guidance.

As the patented original factory, we offer competitive pricing and guaranteed quality.

Contact us for a custom quotation based on your project's specific requirements.

Product Inquiry

HaoHeng Group

Address: Room 1808, Block A, Vanke Cloud City, Jiemei District, Xiamen City, Fujian Province

Business cooperation:

Copyright © HaoHeng (FuJian) Building Materials Technology Co, Ltd. All rights reserved