The Unsung Heroes of Fastening: Self Tapping Screws in Modern Industries

Release Time:

2025-08-11

Source:

Introduction to Self Tapping Screws

Ah, self tapping screws! Those little heroes of the fastening world often go unnoticed, yet they play a critical role in countless industries. From construction to electronics, these tiny gadgets save time and effort, making them a go-to choice for professionals. But what's the big deal, you ask? Well, buckle up as we dive into the fascinating world of self tapping screws!

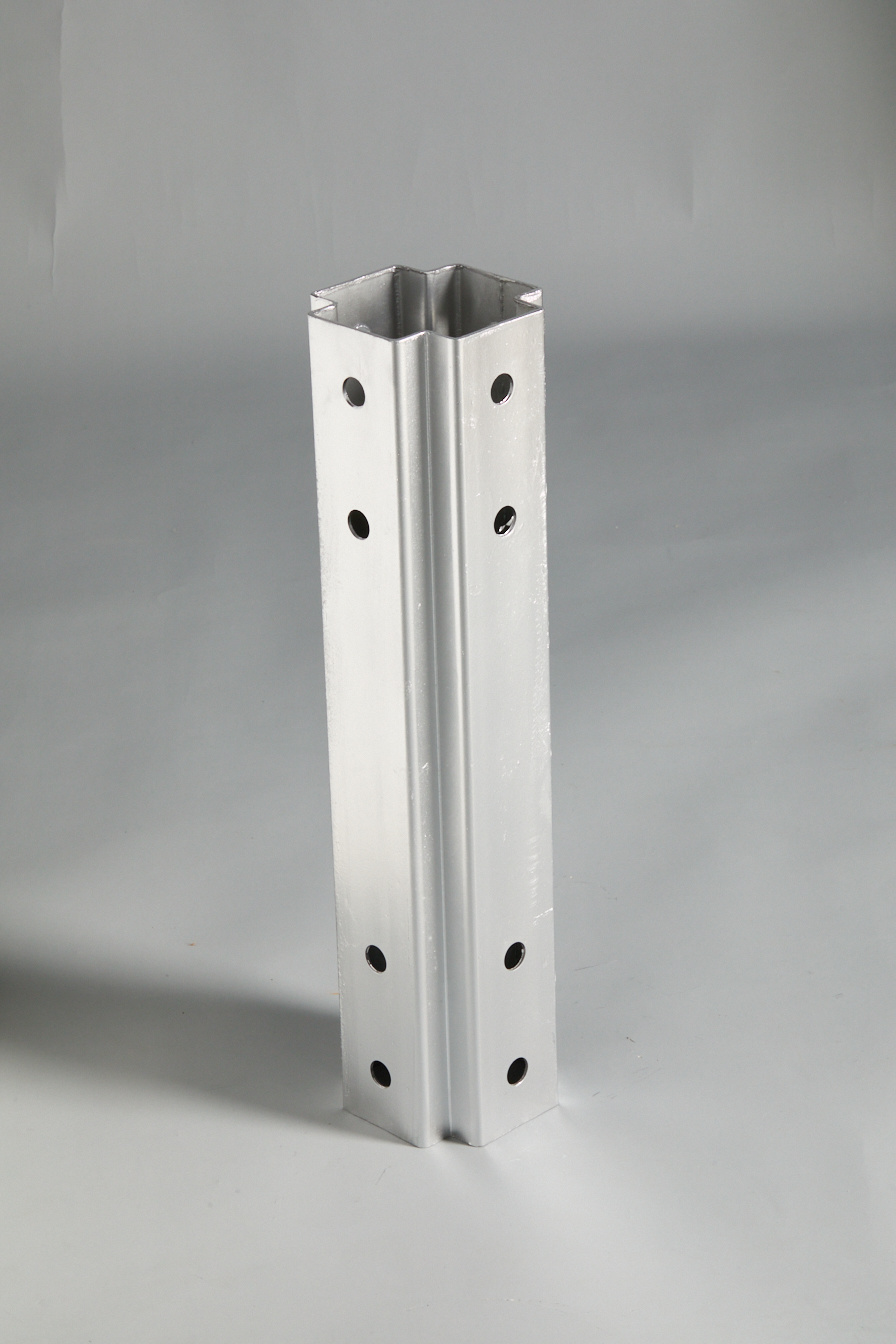

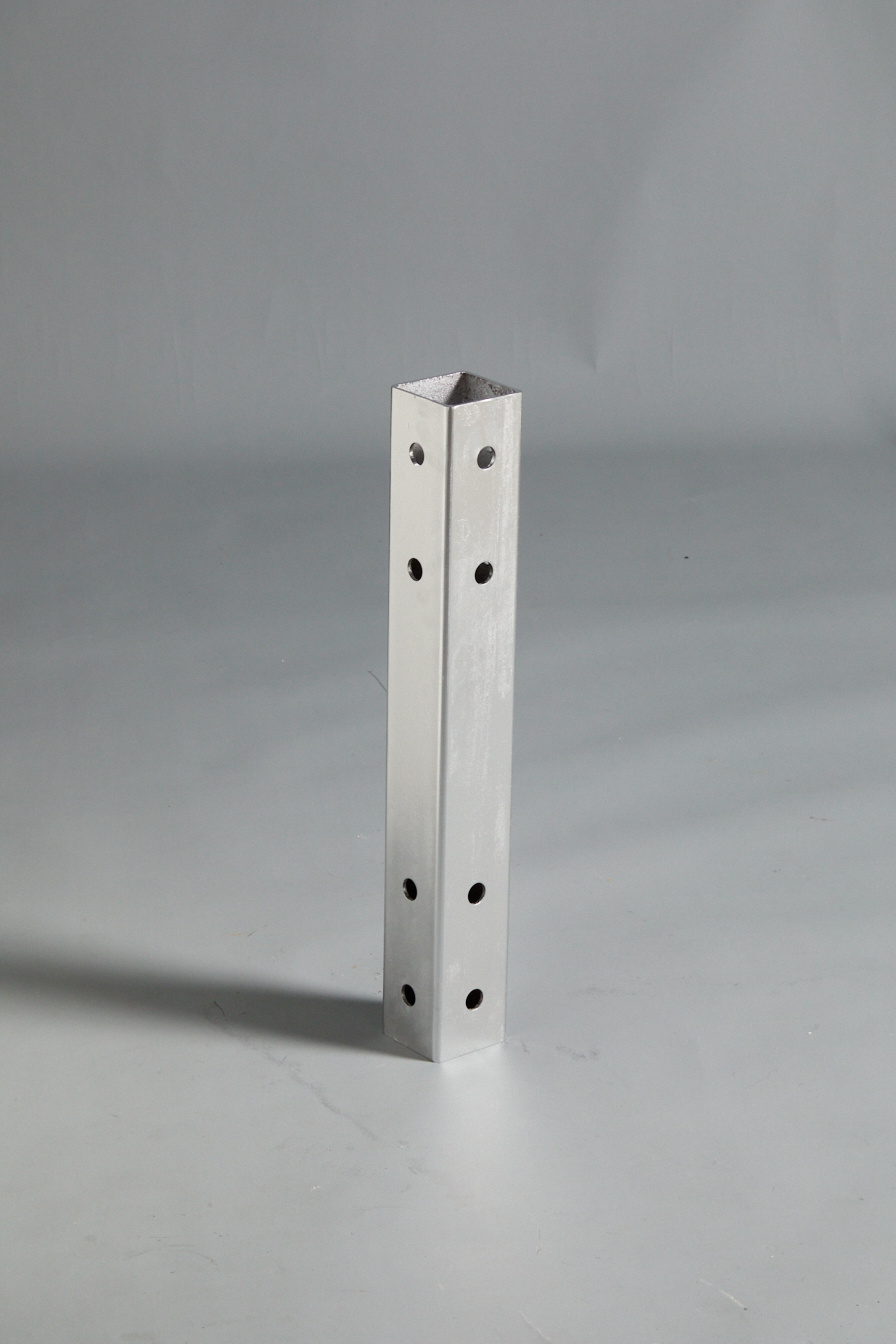

What Are Self Tapping Screws?

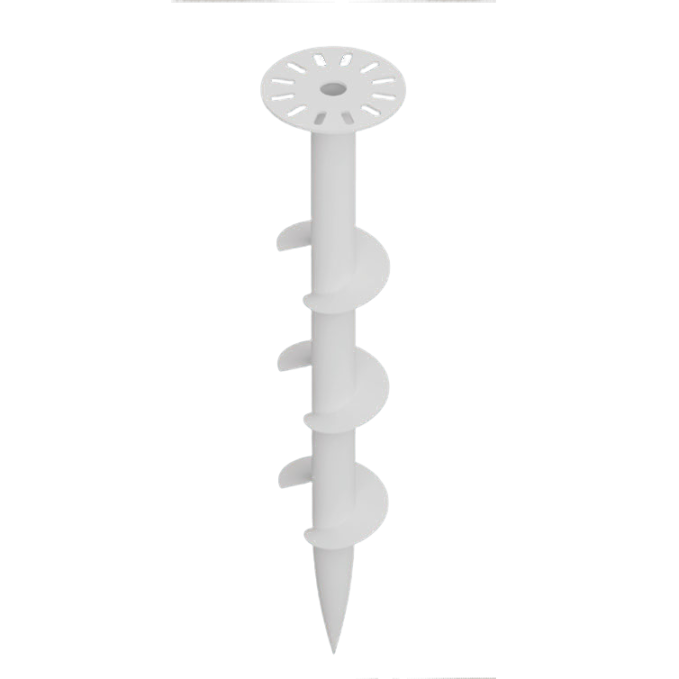

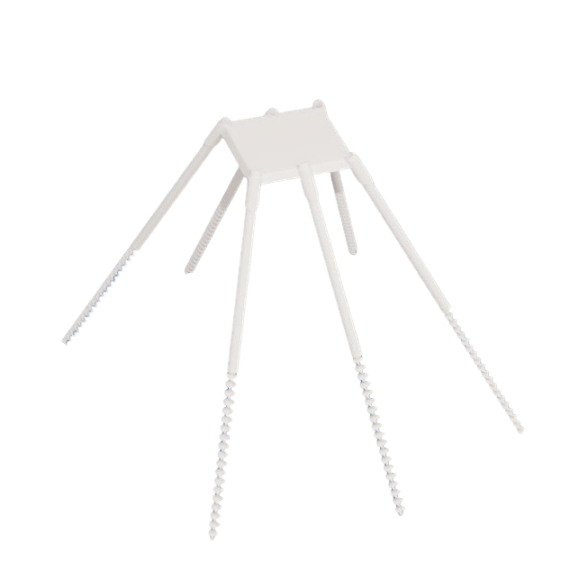

In simple terms, self tapping screws are specially designed to create their own hole as they are driven into materials. Unlike traditional screws that require pre-drilled holes, these bad boys have sharp, pointed ends that allow them to dig right in. This nifty feature not only speeds up the installation process but also reduces the need for additional tools. Talk about a win-win!

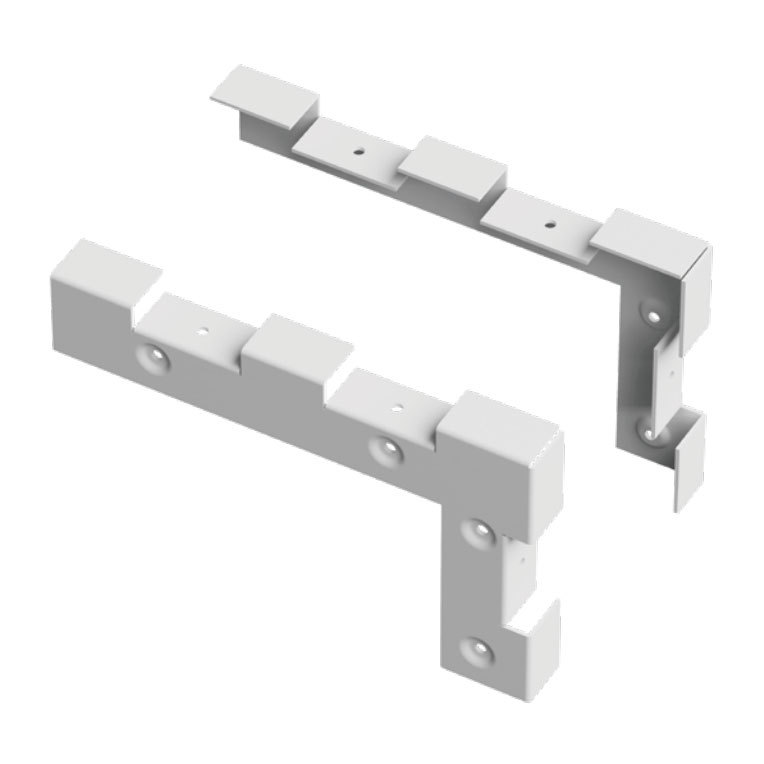

Types of Self Tapping Screws

There's more than meets the eye with self tapping screws. They come in various types, each tailored for specific applications. Here's a quick rundown:

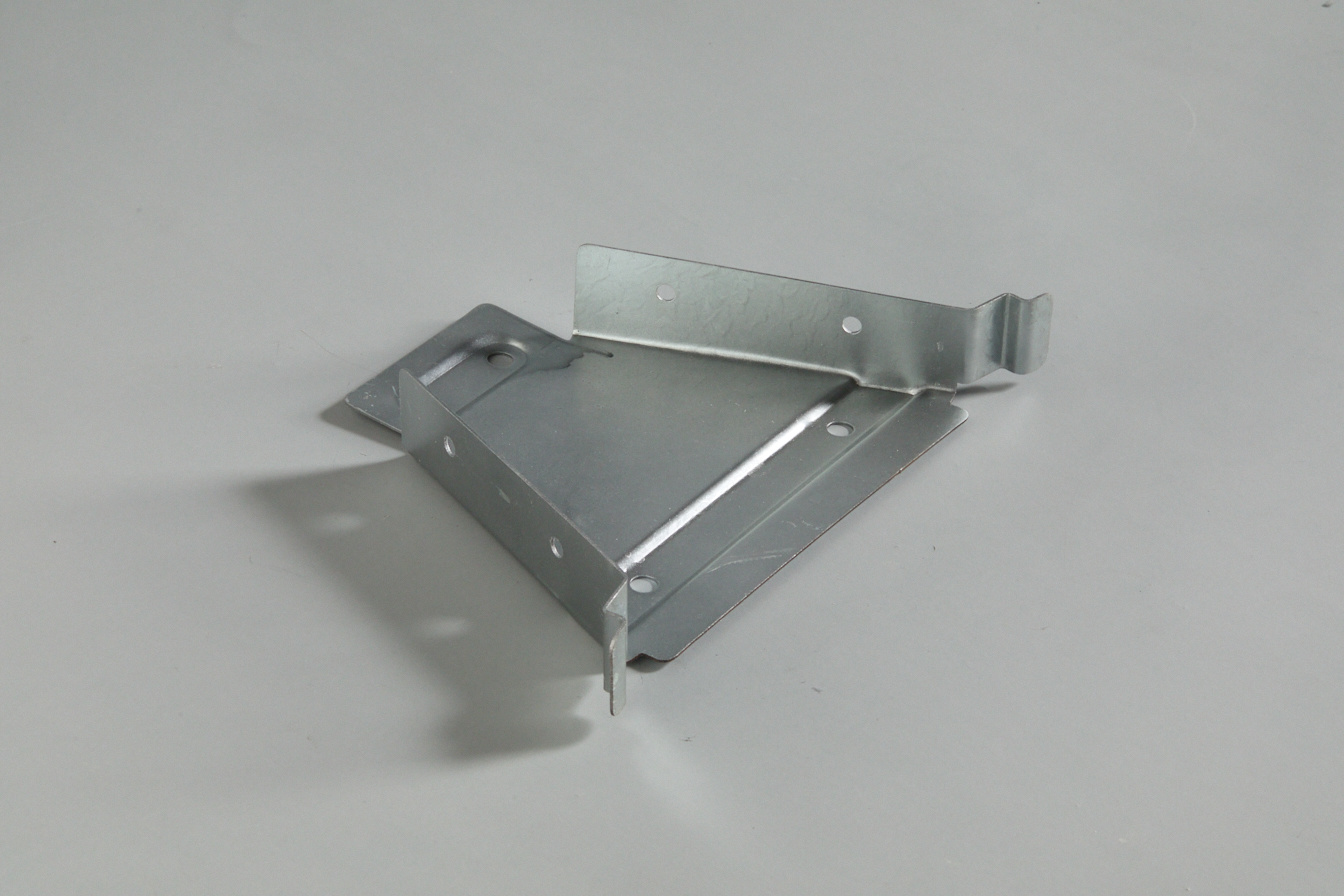

- Thread Cutting Screws: These screws cut threads into the material, making them ideal for softer materials like wood or plastic.

- Thread Forming Screws: Perfect for metal, these create a tight fit without cutting into the material, providing superior holding power.

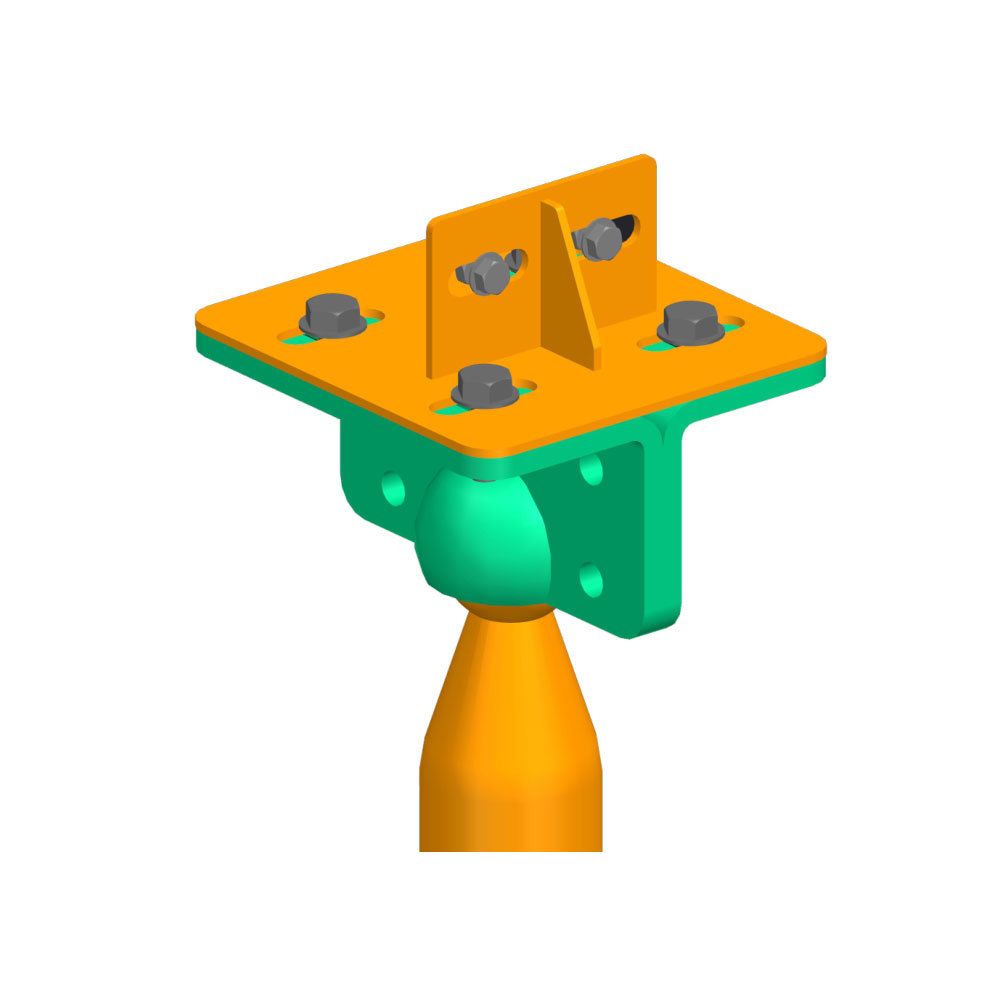

- Self Drilling Screws: Equipped with a drill point, these screws can penetrate metal without any pre-drilling. Super handy, right?

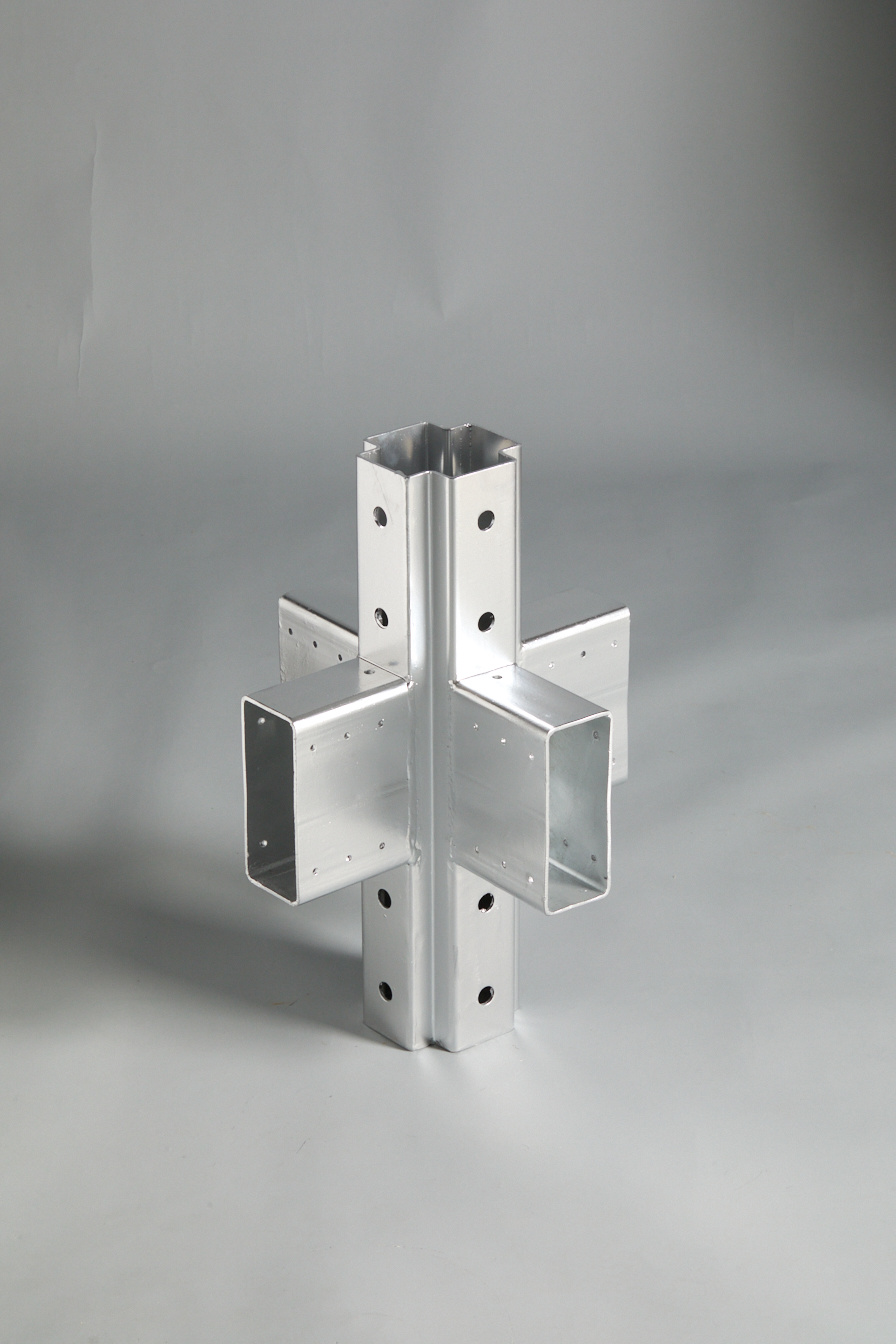

Applications Across Industries

Self tapping screws are the Swiss Army knives of the fastening world, finding their way into various sectors:

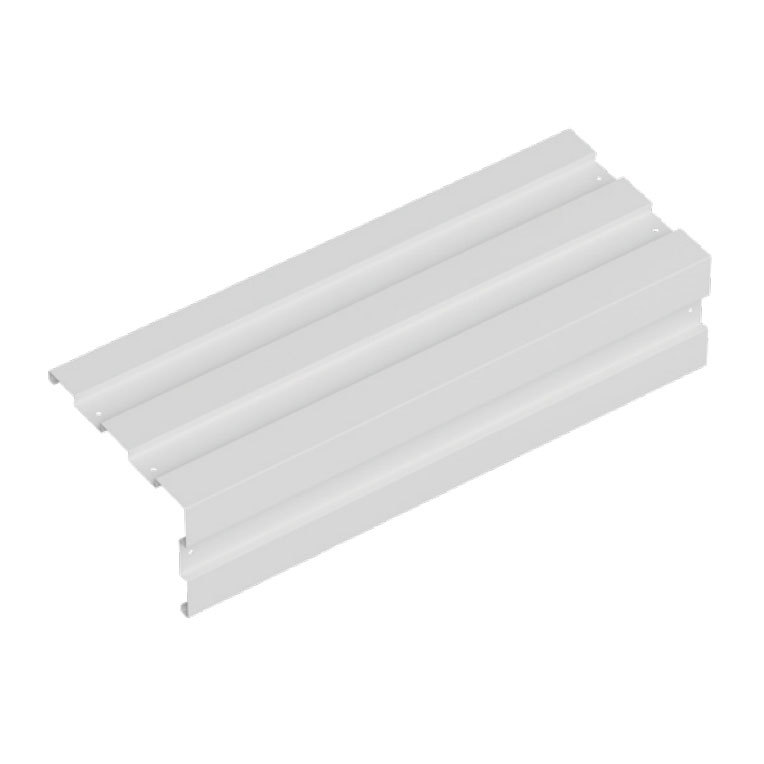

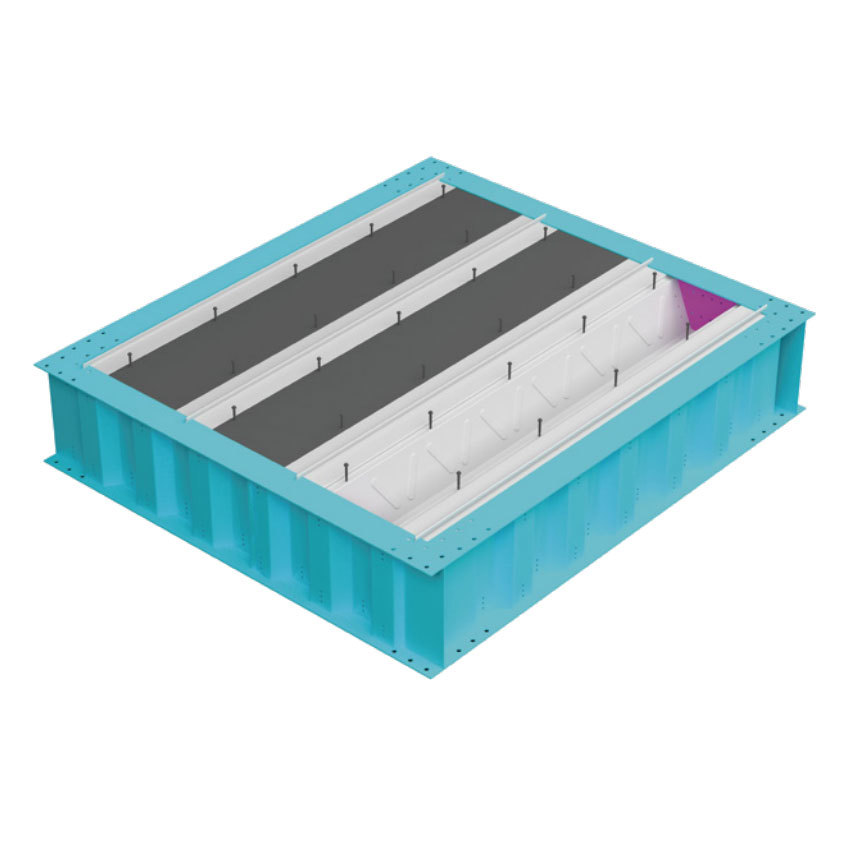

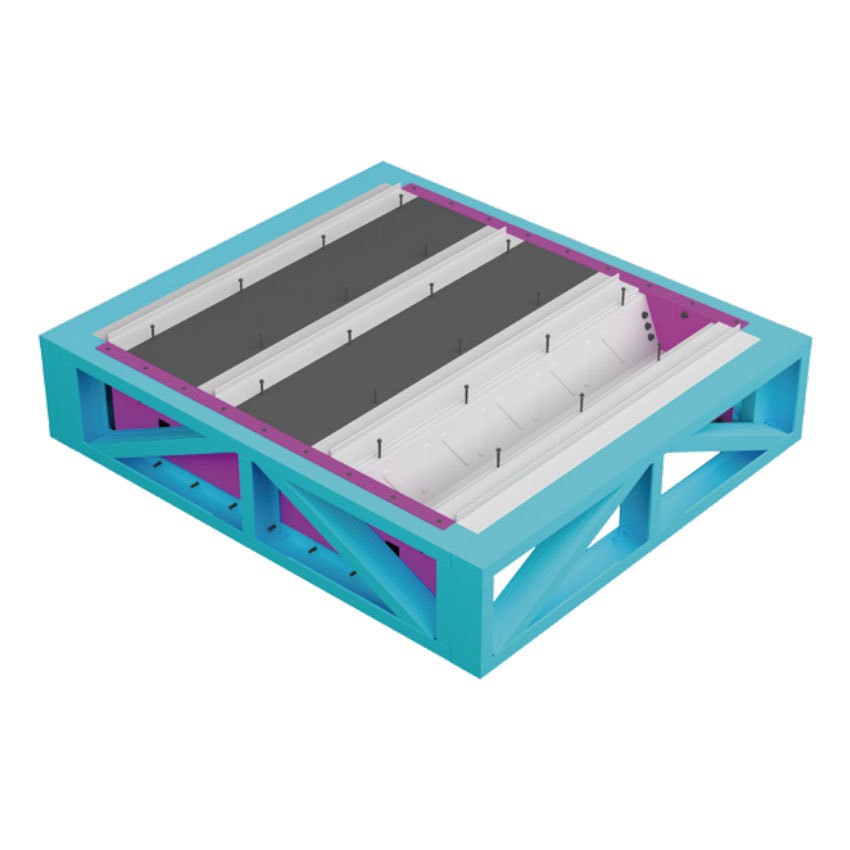

- Construction: Builders love them for their speed and reliability when fastening drywall, roofing, and metal structures.

- Automotive: In the automotive industry, these screws are used to assemble parts, ensuring everything holds together during those bumpy rides.

- Electronics: You'll find self tapping screws securing circuit boards and housing units, proving that even the tiniest components need robust fastening solutions.

Advantages of Using Self Tapping Screws

Now, let's get into why you should consider switching to self tapping screws:

- Time-Saving: They eliminate the need for pre-drilling, reducing installation time significantly.

- Cost-Effective: Fewer tools and less labor mean lower overall costs for projects.

- Versatility: Suitable for a wide range of materials, making them an all-in-one solution.

Challenges and Considerations

Of course, no product is without its pitfalls. Here are a few things to keep in mind:

- Material Compatibility: Not all self tapping screws work well with every material, so it's essential to choose wisely.

- Over-tightening: It's easy to get carried away and strip the screw or damage the material. Gentle pressure is key!

- Corrosion Resistance: In outdoor applications, ensure your screws are treated to withstand the elements.

The Future of Self Tapping Screws

As industries evolve, so do the tools we use. With advancements in materials and manufacturing processes, self tapping screws are becoming even more efficient. Innovations like improved coatings for corrosion resistance and designs that reduce installation torque are on the horizon. The future looks bright for these unsung heroes!

Conclusion

So, next time you come across self tapping screws, take a moment to appreciate their contribution to modern industry. They may be small, but they pack a punch when it comes to efficiency and reliability. Whether you're a DIY enthusiast or a seasoned professional, these little wonders are worth having in your toolkit. Remember, it's not just about the size of the screw; it's about the impact it makes!

Related Information

HaoHeng Group

Address: Room 1808, Block A, Vanke Cloud City, Jiemei District, Xiamen City, Fujian Province

Business cooperation:

Copyright © HaoHeng (FuJian) Building Materials Technology Co, Ltd. All rights reserved