Mastering Self Tapping Screws: Essential Tips and Tricks

Release Time:

2025-08-11

Source:

Introduction to Self Tapping Screws

When it comes to DIY projects or professional construction, self tapping screws are your best pals. These little wonders, often overlooked, can save you time and frustration. But hold your horses! There are some crucial considerations to keep in mind before diving in. Let's unpack the ins and outs of self tapping screws.

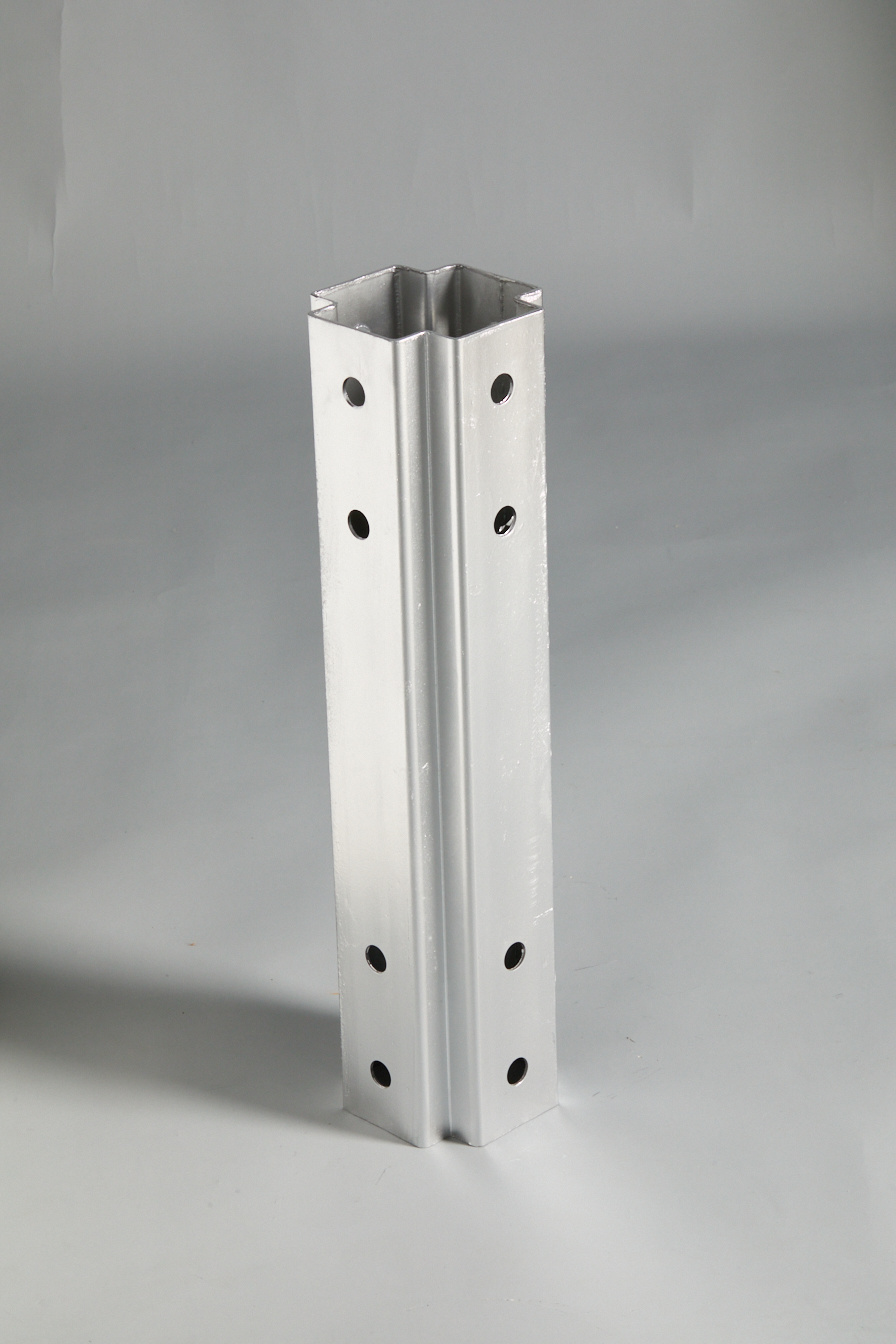

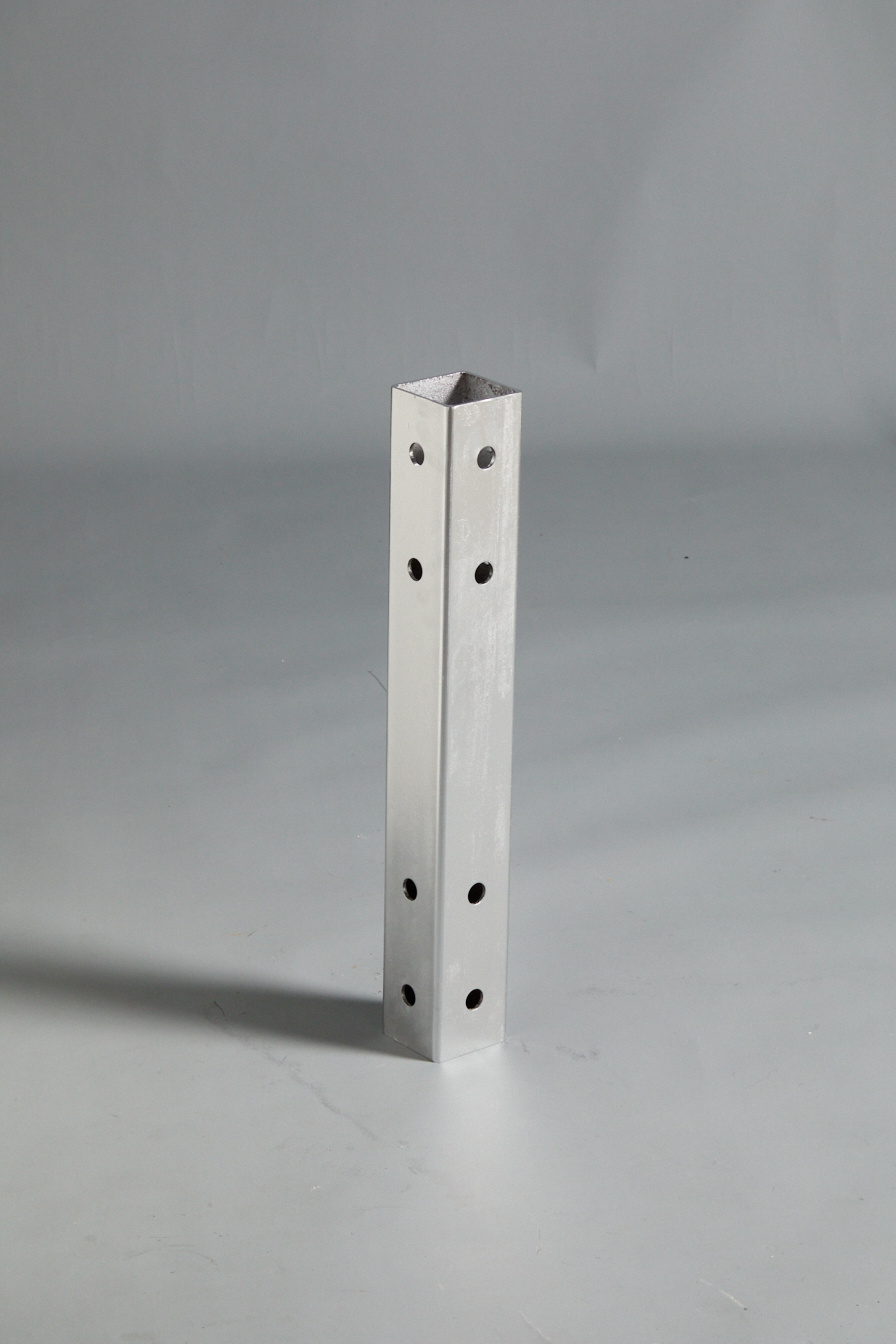

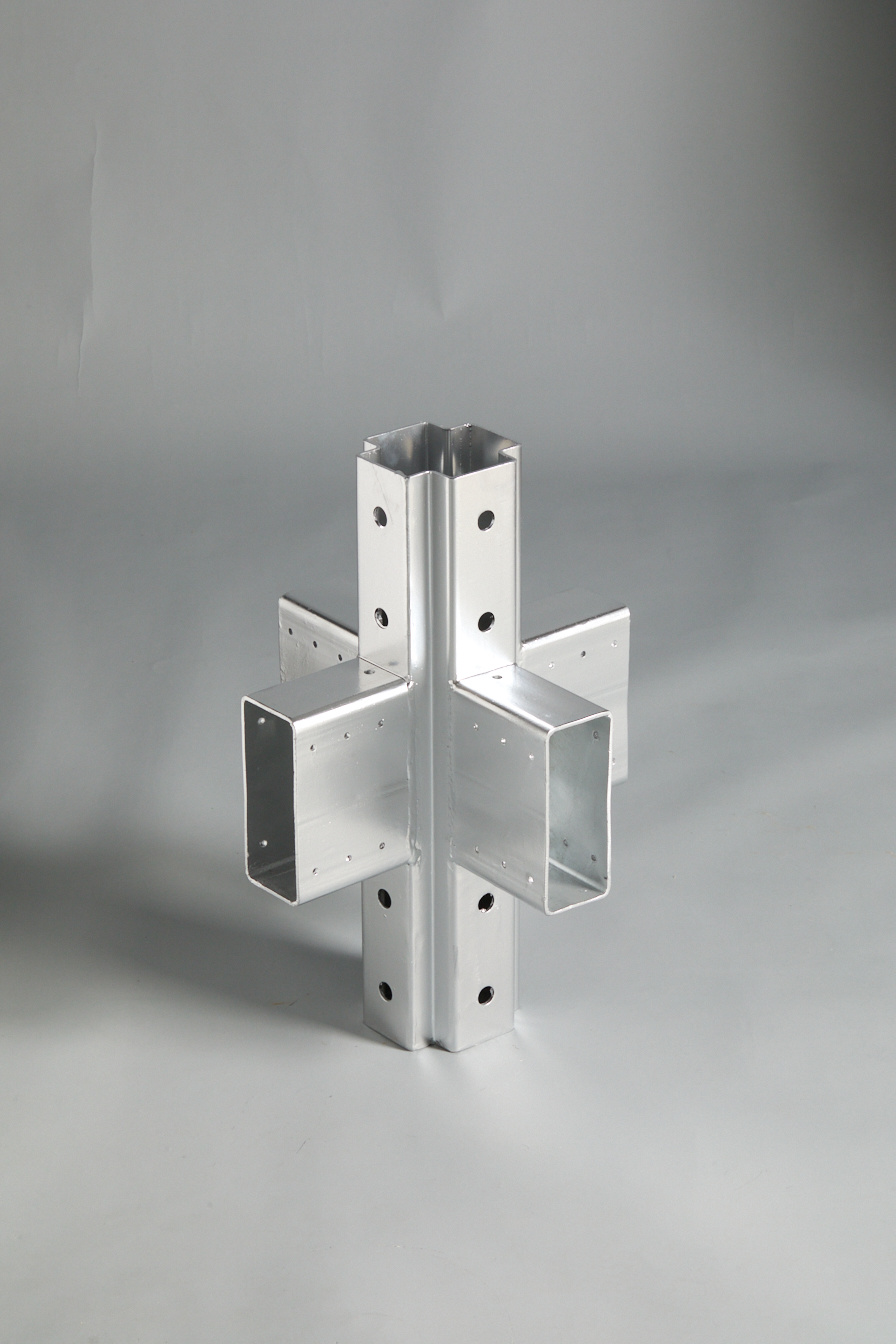

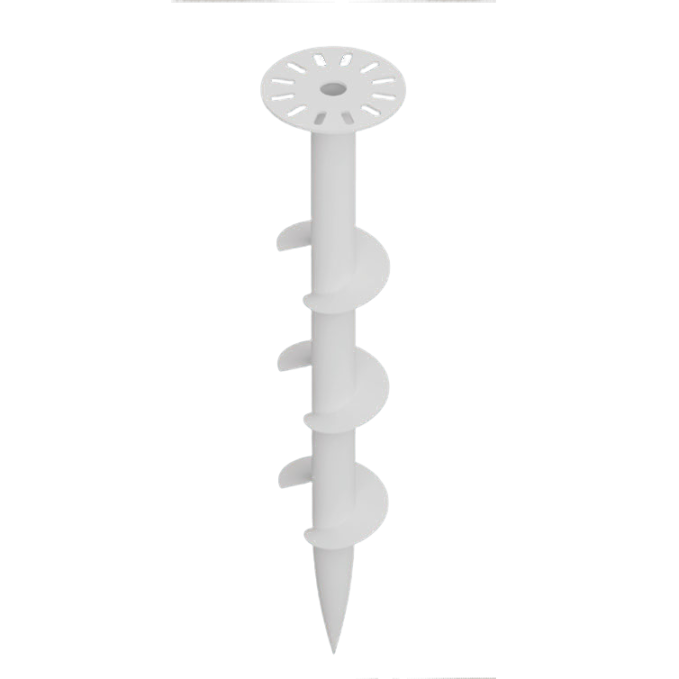

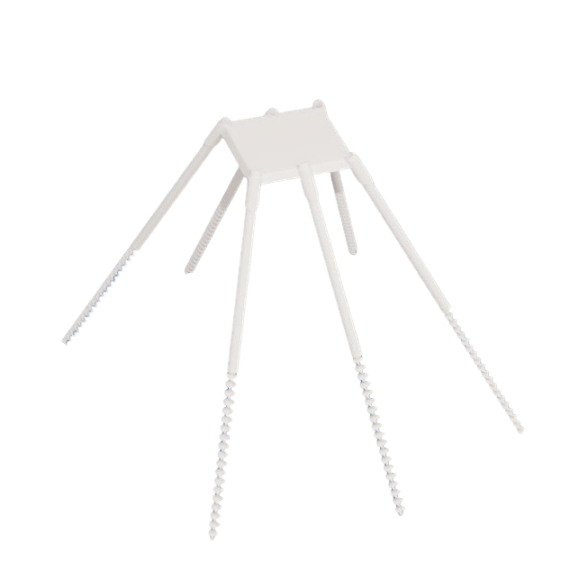

What Are Self Tapping Screws?

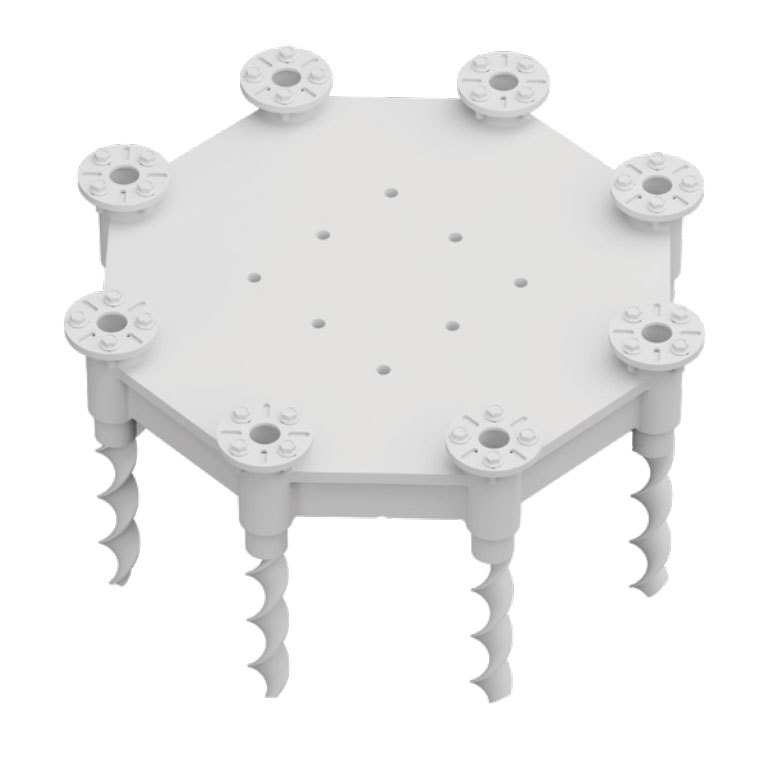

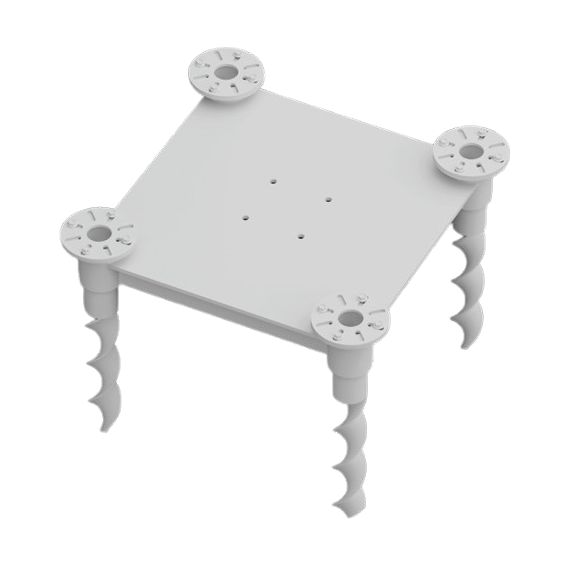

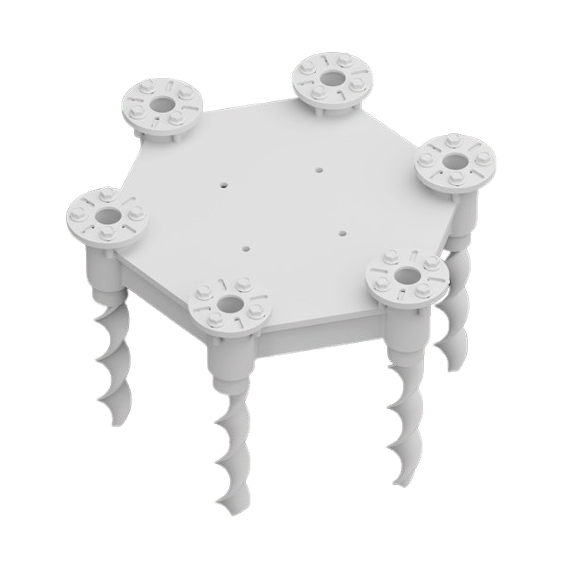

Self tapping screws are designed to create their own hole as they are driven into materials. Unlike regular screws that need a pre-drilled hole, these handy fasteners can bite into wood, metal, and plastic, making them a go-to choice for many. They come in various sizes and styles, but the basic principle remains the same: tap and go!

Choosing the Right Type

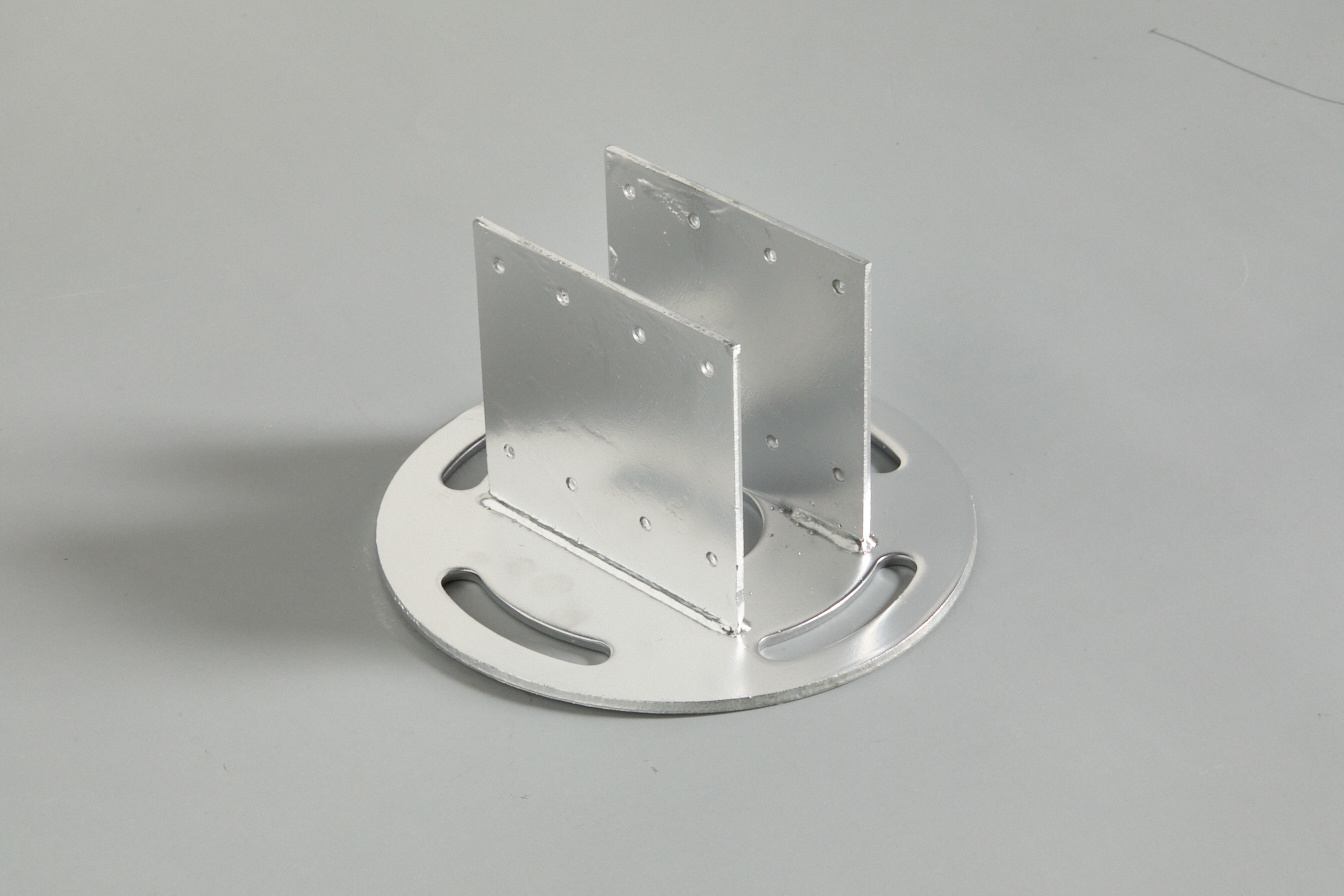

Before you start your project, it's imperative to choose the right type of self tapping screws. Not all screws are created equal, and using the wrong one can lead to a host of problems. For instance, if you're working with metal, make sure to grab some sheet metal screws. They have a sharper point and can handle the hardness of the material.

Material Matters

Also, consider the material of the screw itself. Stainless steel is excellent for outdoor projects due to its resistance to rust, while zinc-coated screws are great for indoor uses. Don't skimp on quality; a rusty screw could ruin your whole project!

Preparation Is Key!

Now that you have your screws, let's talk preparation. Just like baking a cake, you wouldn't skip the measuring, right? The same goes for your screws. Here are some tips:

- Always clean the surface where you'll be screwing. Dust and debris can affect the screw's grip.

- If you're working with metal, consider using a lubricant to ease the tapping process.

- Use a pilot hole if you're uncertain about the material. It can prevent splitting in wood and make the process smoother.

Driving the Screw

Alright, you're ready to roll! But wait, there's an art to driving self tapping screws. Here's the scoop:

- Use a power drill or driver with adjustable speed. Start slow and gradually increase speed.

- Keep the screw perpendicular to the surface. This ensures it goes in straight and doesn't strip.

- Don't overdrive! It's tempting to force it in, but this can damage the screw or the material.

Common Mistakes to Avoid

Even seasoned pros can stumble when it comes to self tapping screws. Here are some no-no's:

- Ignoring the right size: A too-small screw won't hold, while an oversized one can cause cracks.

- Using the wrong drill bit: Always match the drill bit to the screw size.

- Not checking for obstructions: Make sure there's nothing behind the surface that could get in the way.

Conclusion: Wrap It Up!

In conclusion, self tapping screws are a fantastic tool when used correctly. They can save time and make your projects a breeze, provided you follow the necessary precautions. So, gear up, grab your screws, and let your creativity flow! Happy screwing!

Related Information

HaoHeng Group

Address: Room 1808, Block A, Vanke Cloud City, Jiemei District, Xiamen City, Fujian Province

Business cooperation:

Copyright © HaoHeng (FuJian) Building Materials Technology Co, Ltd. All rights reserved