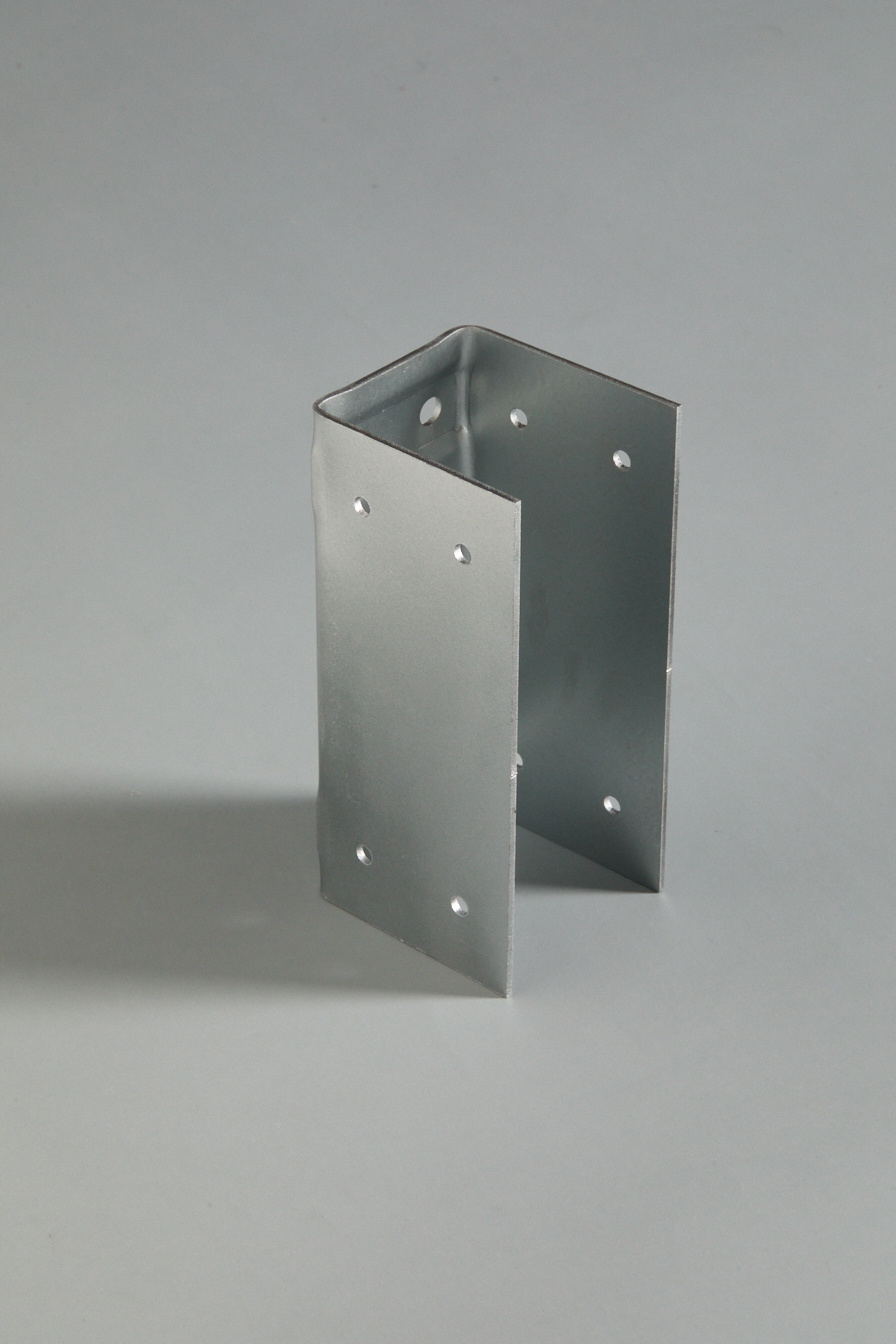

“Quality 153 Inner Flipped Edge” Becomes New Benchmark in Precision Manufacturing

Release Time:

2025-08-25

Source:

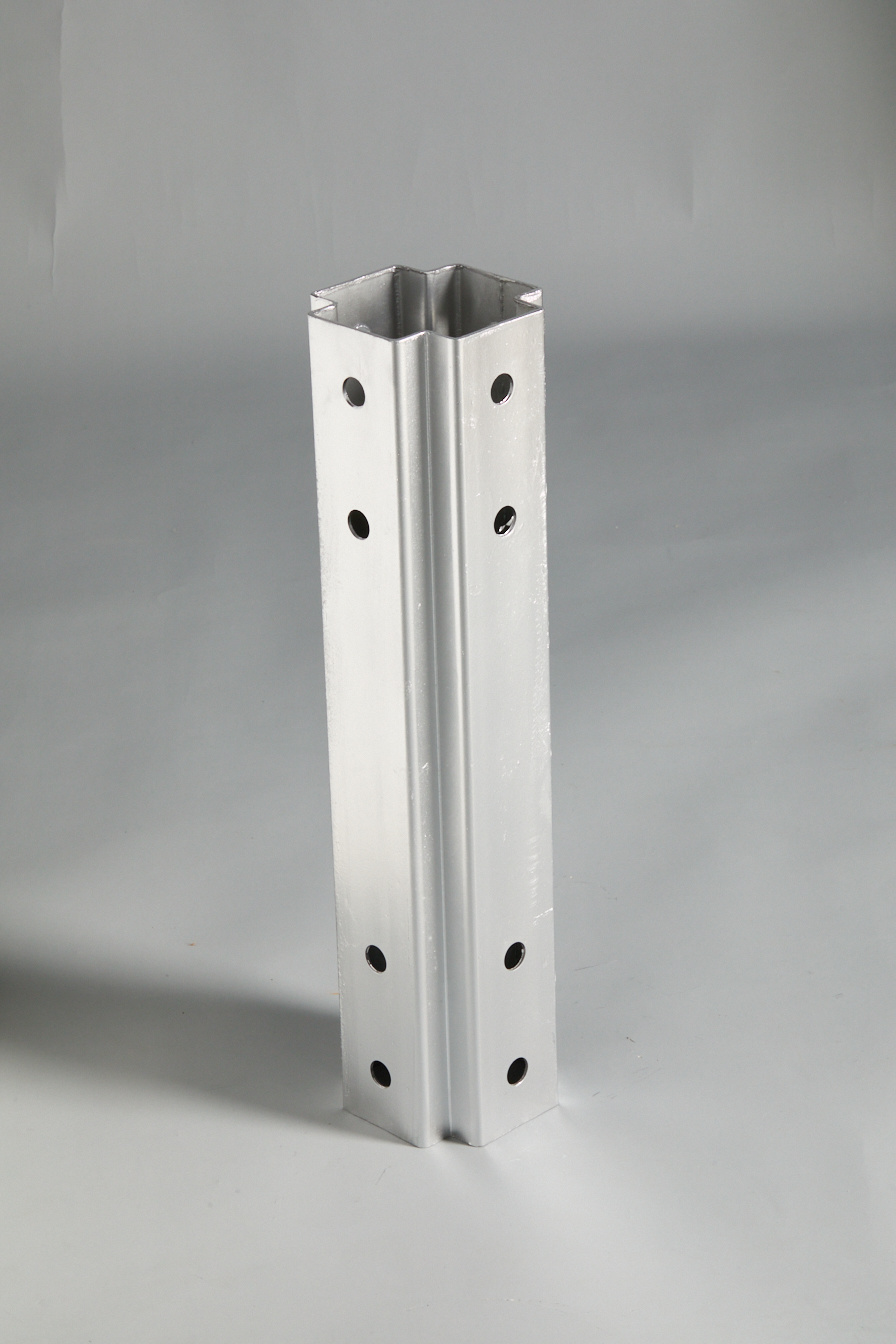

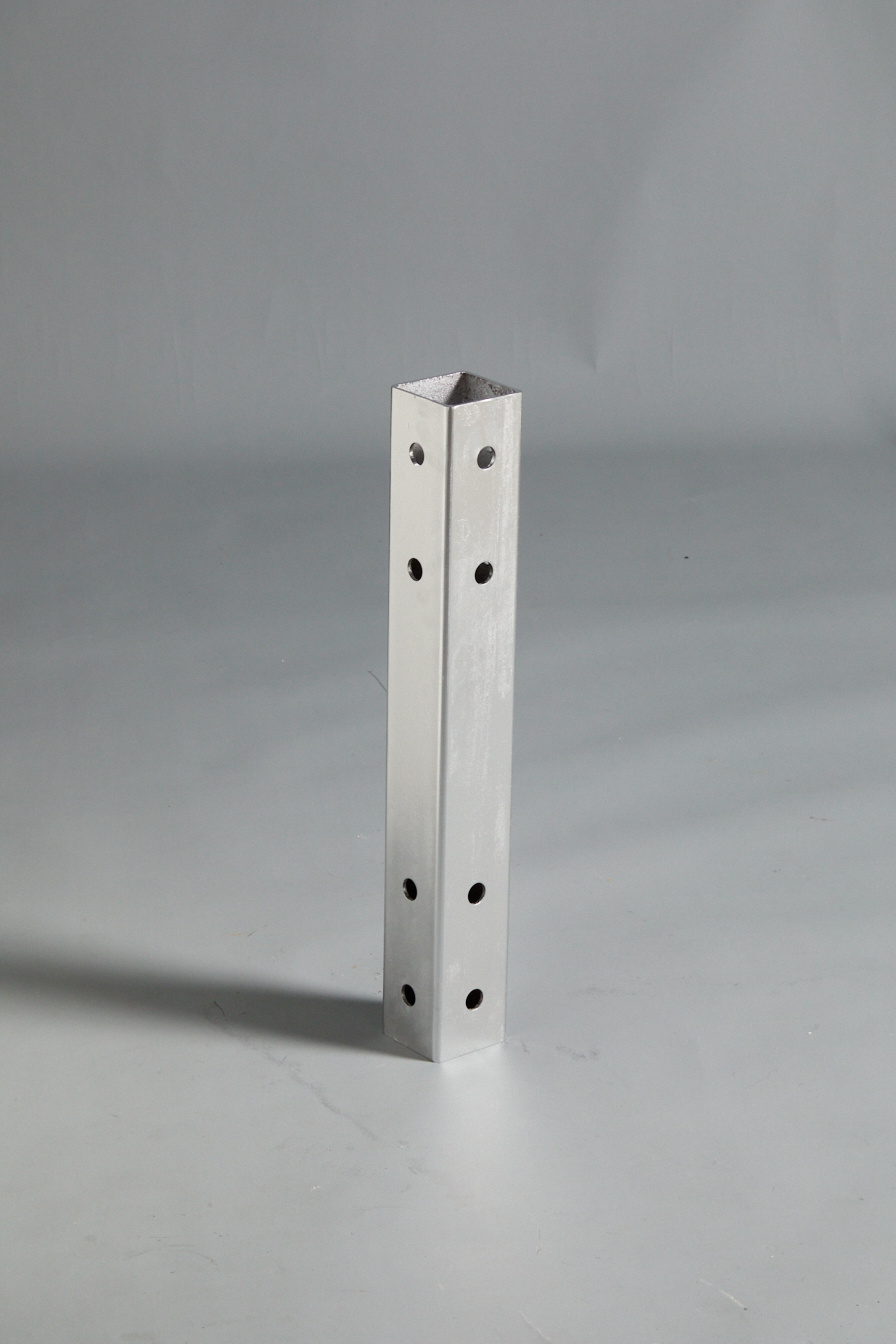

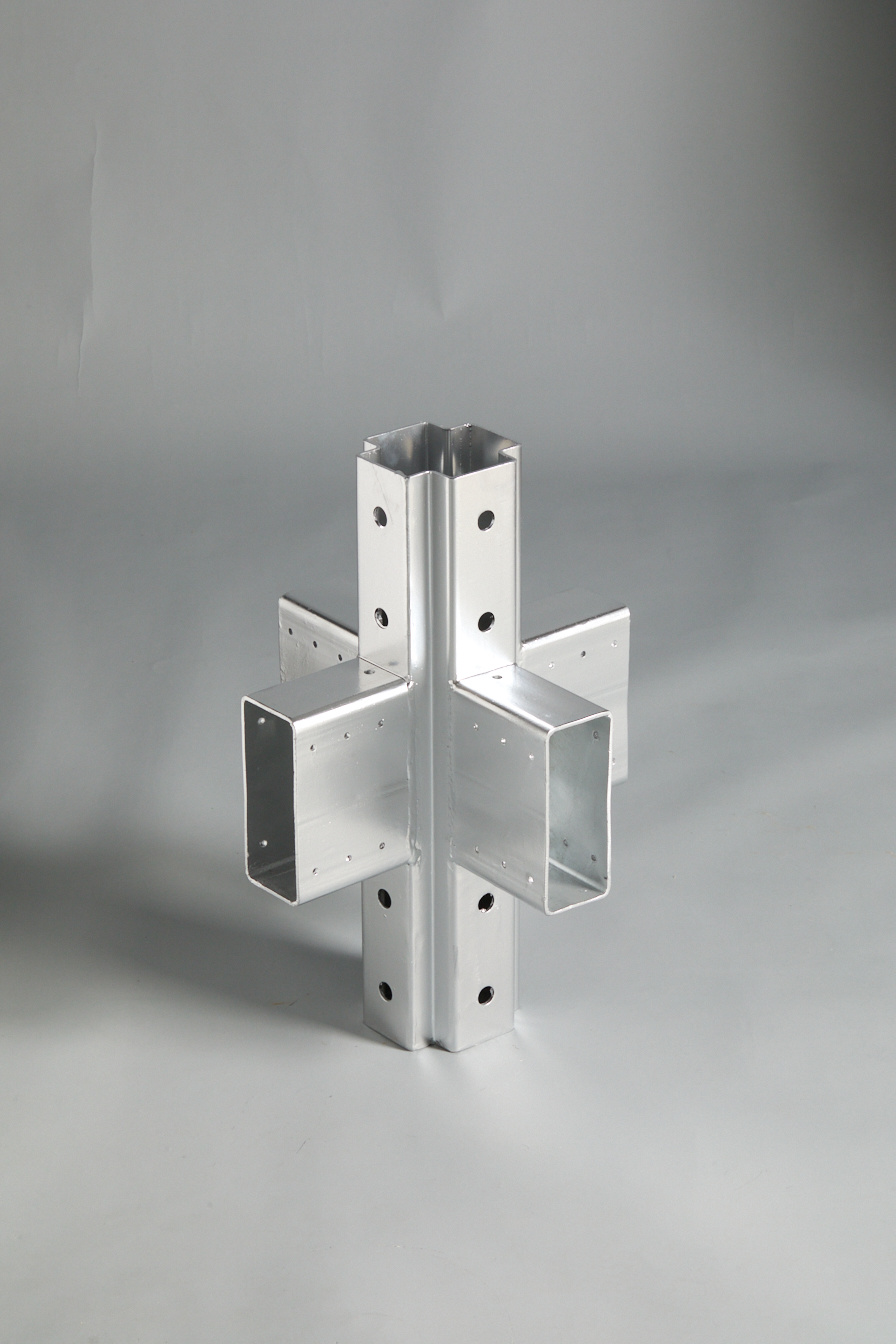

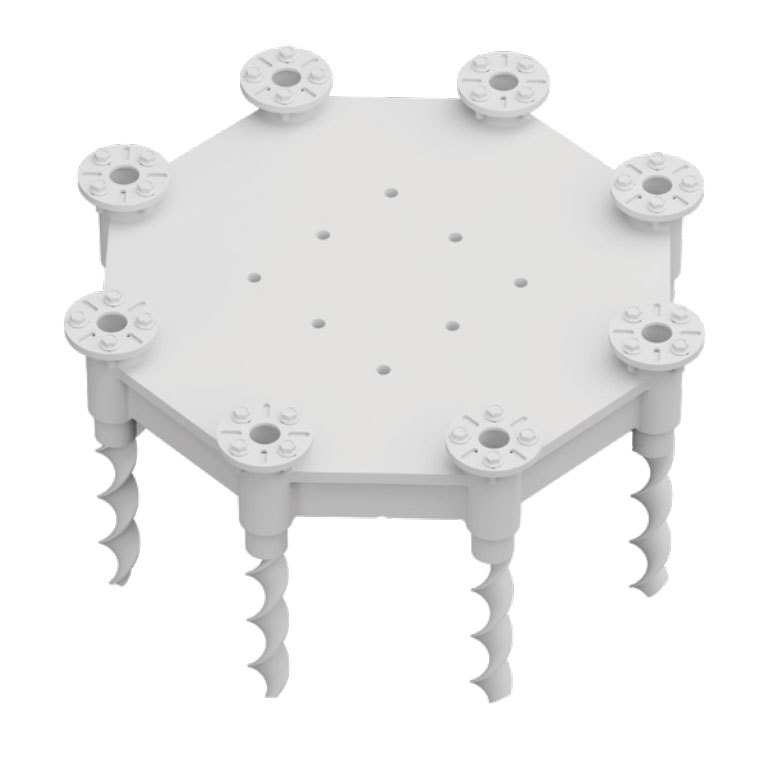

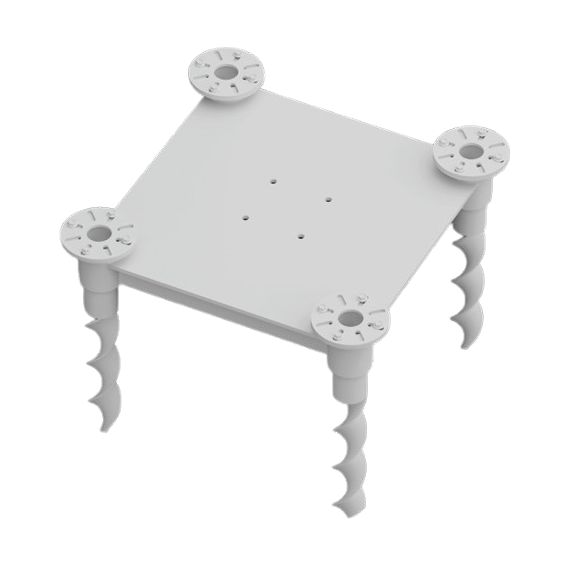

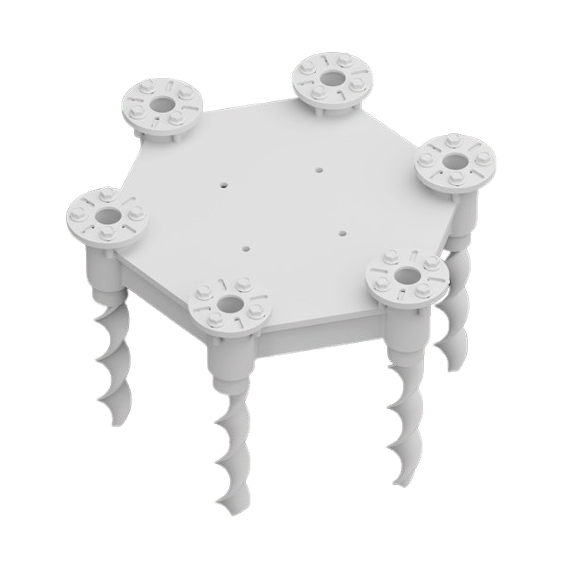

With global industries moving toward higher performance, durability, and safety standards, innovative component technologies are increasingly valued by manufacturers. Recently, the quality 153 inner flipped edge has attracted attention in the fields of automotive, aerospace, heavy machinery, and precision engineering, becoming a trusted structural design that ensures both strength and efficiency.

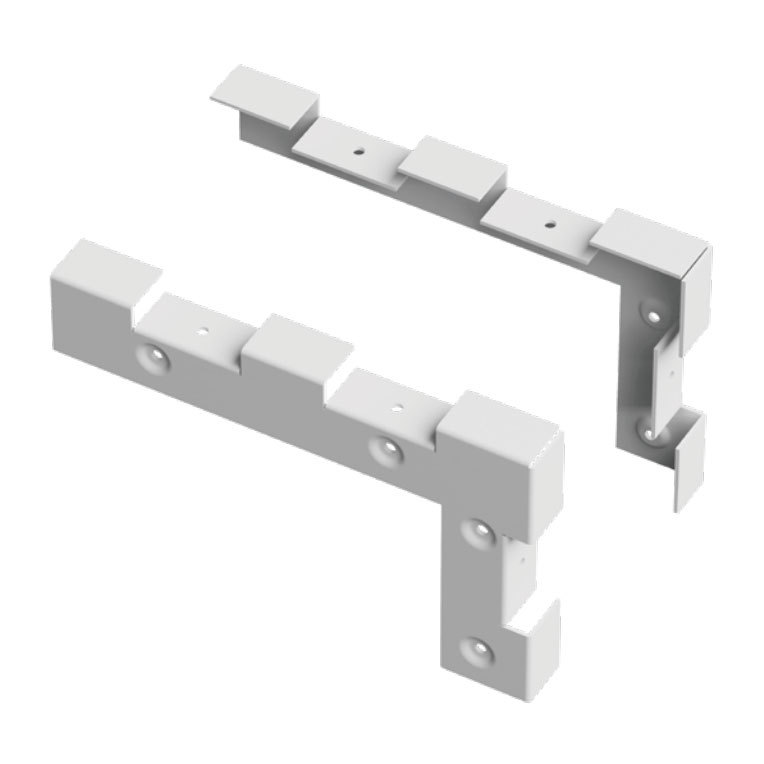

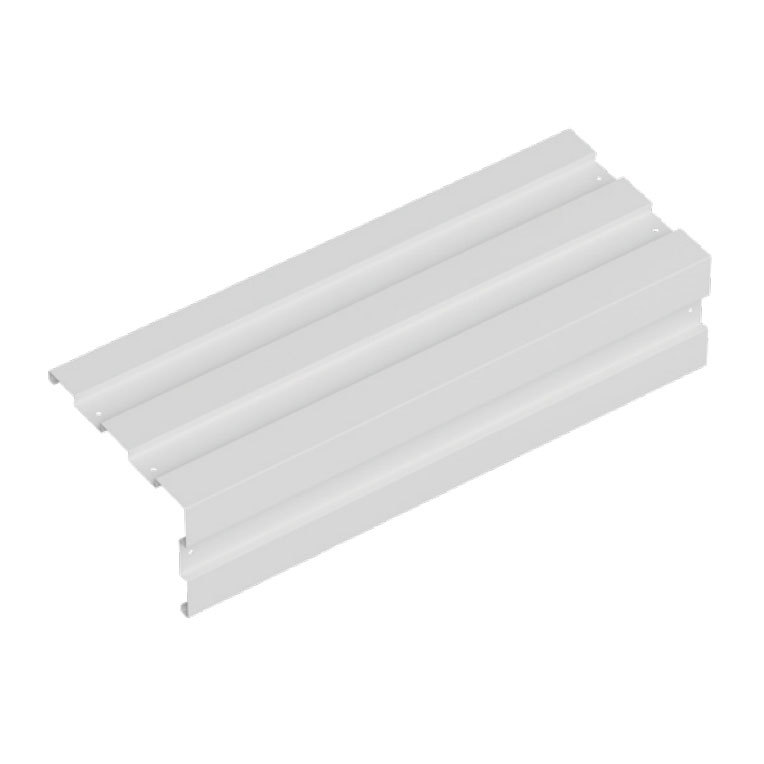

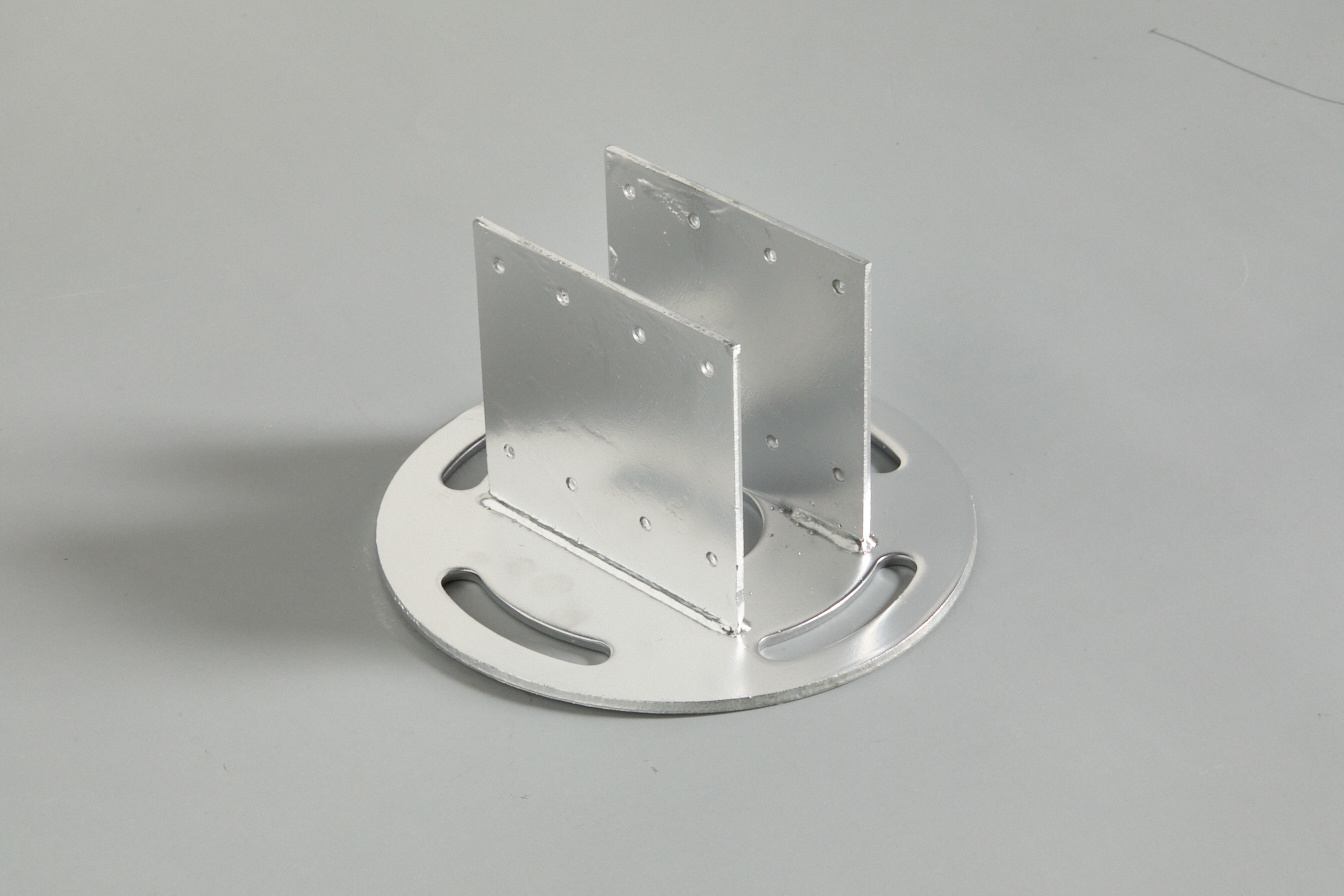

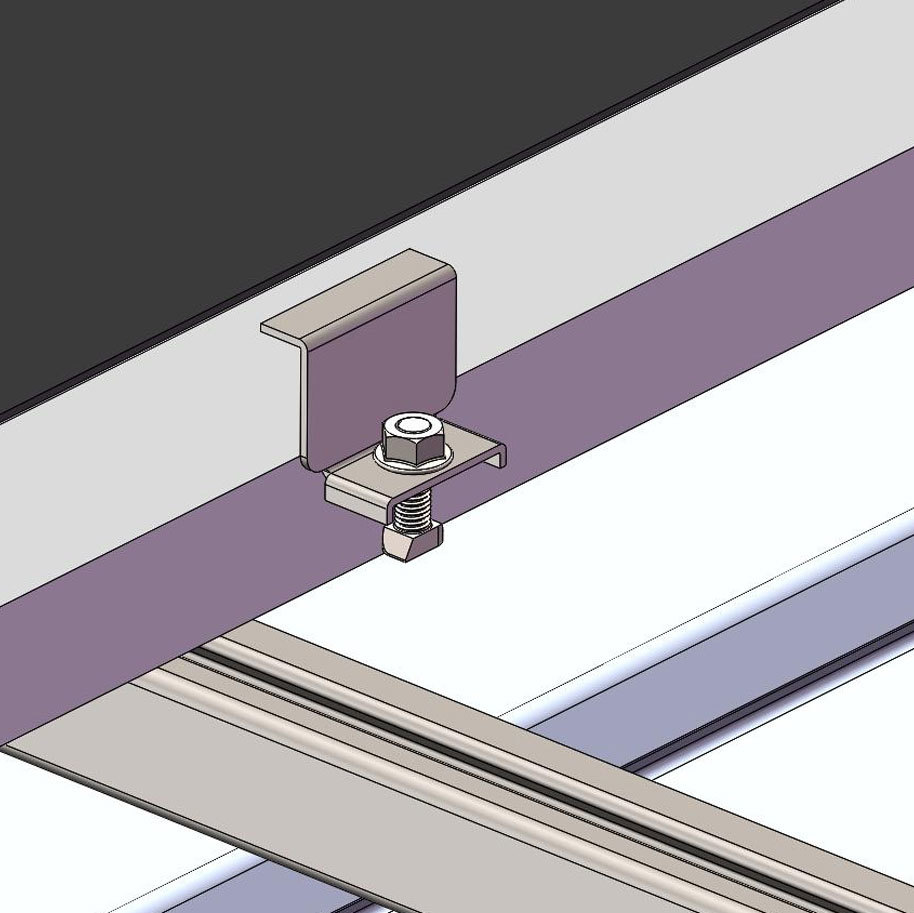

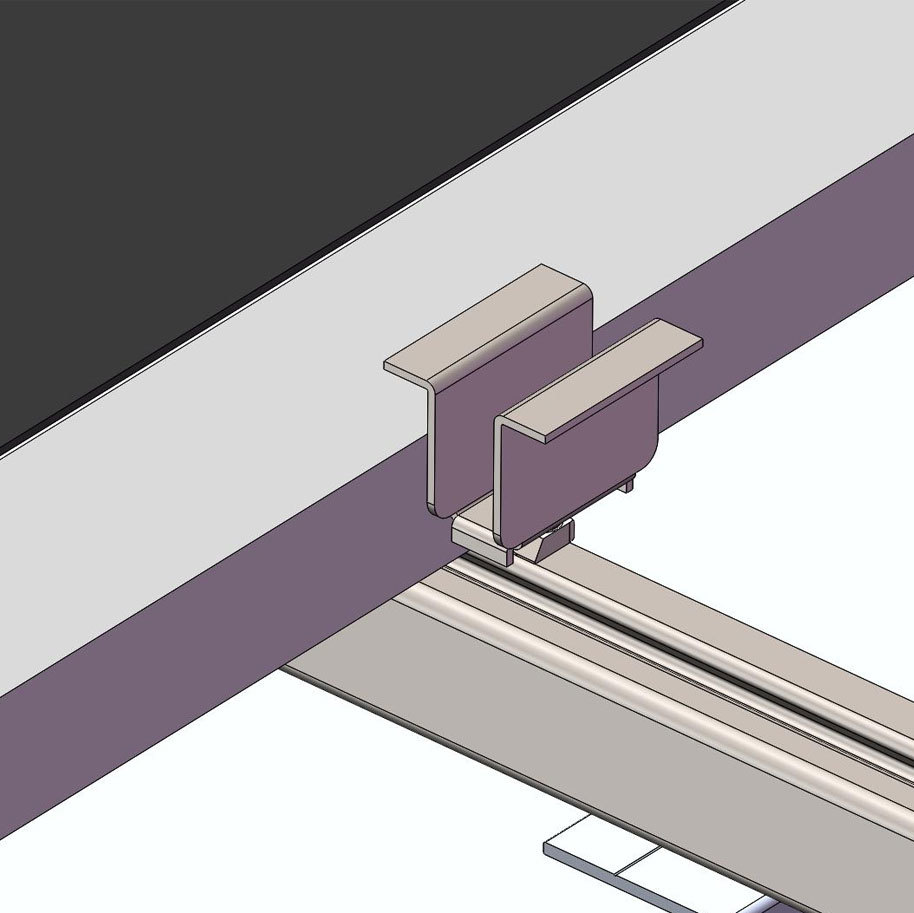

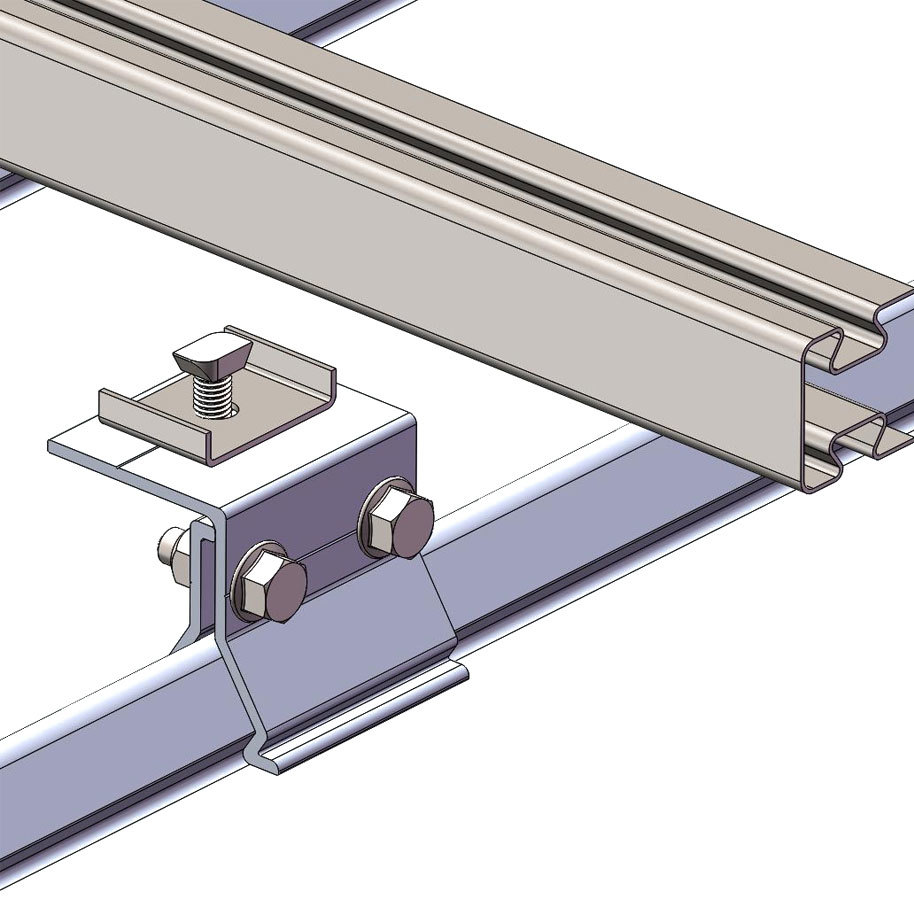

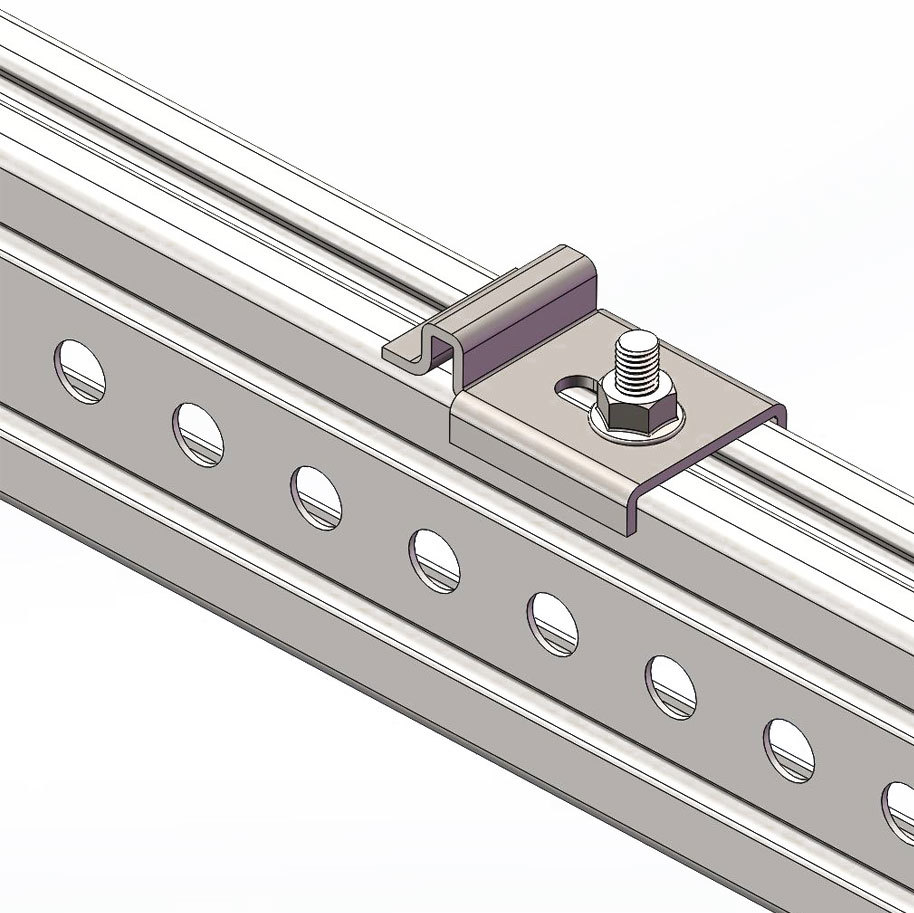

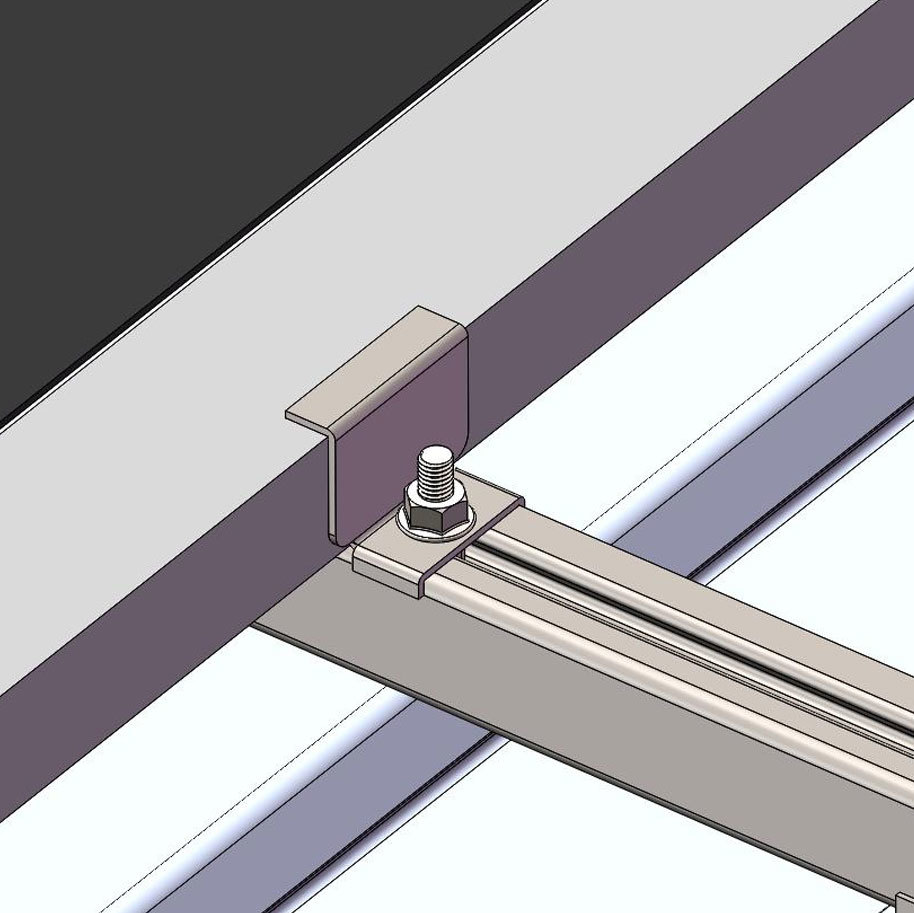

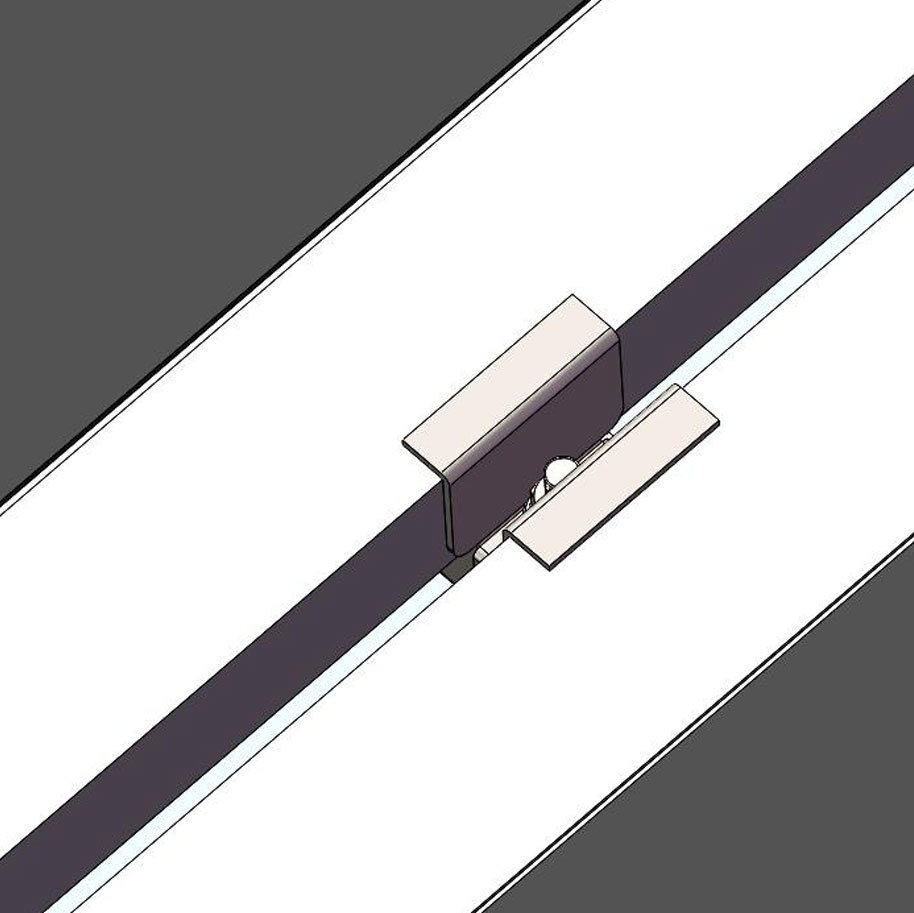

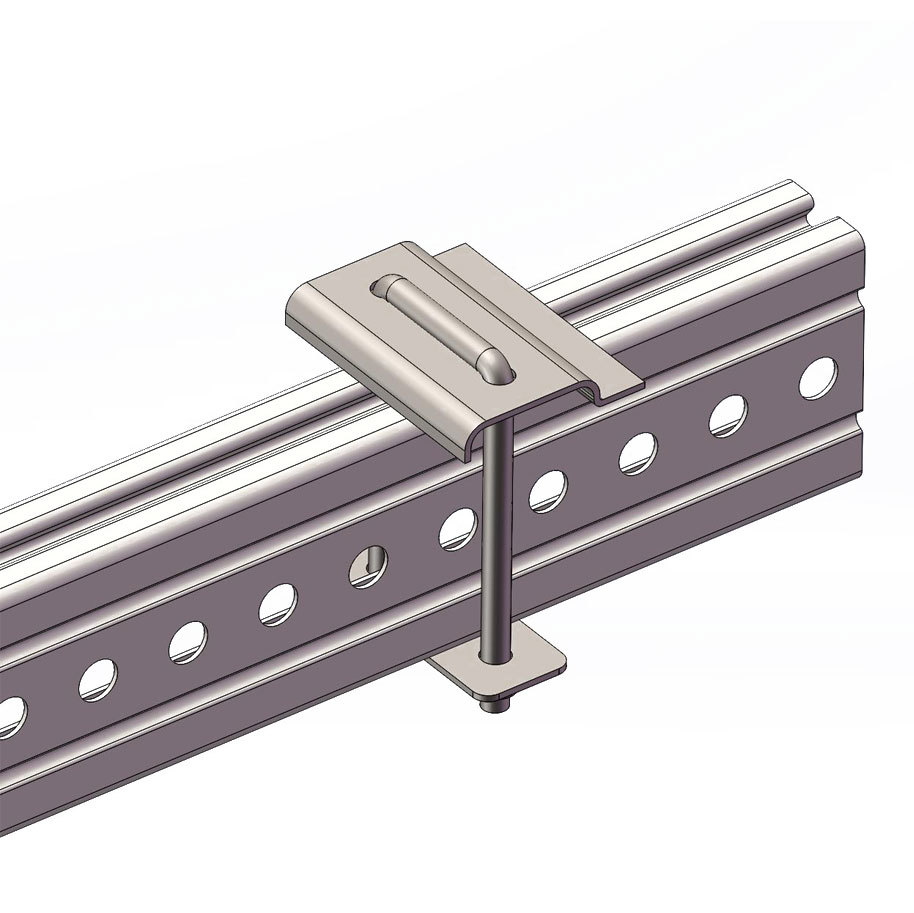

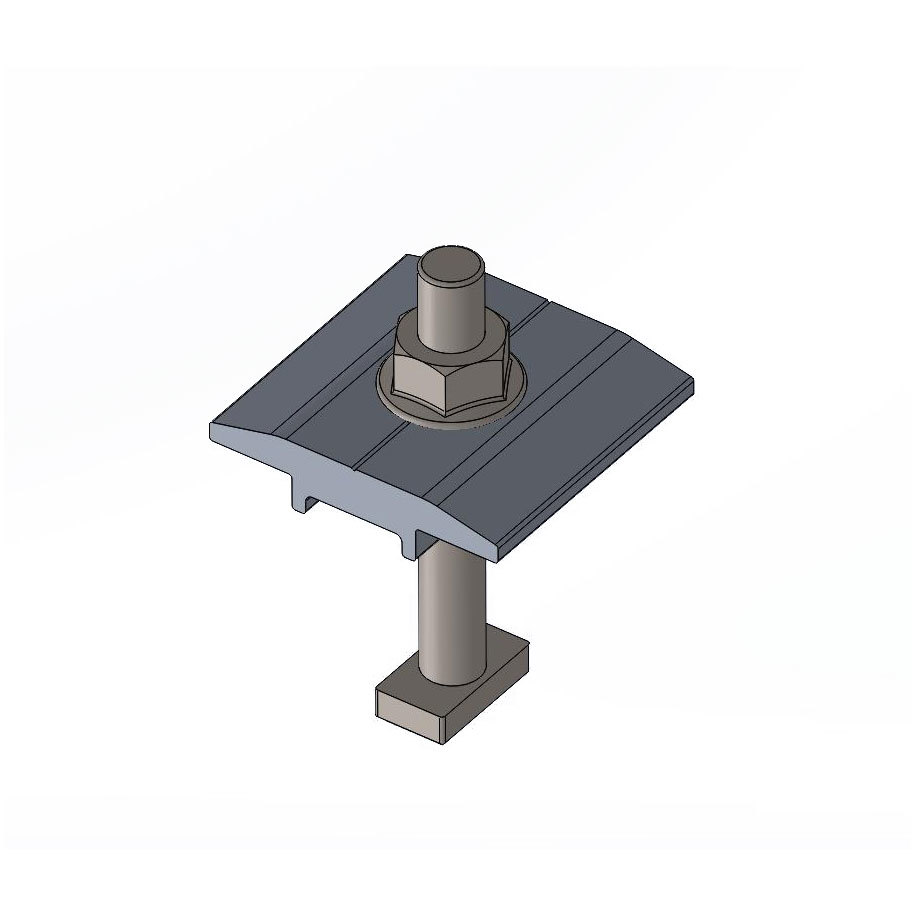

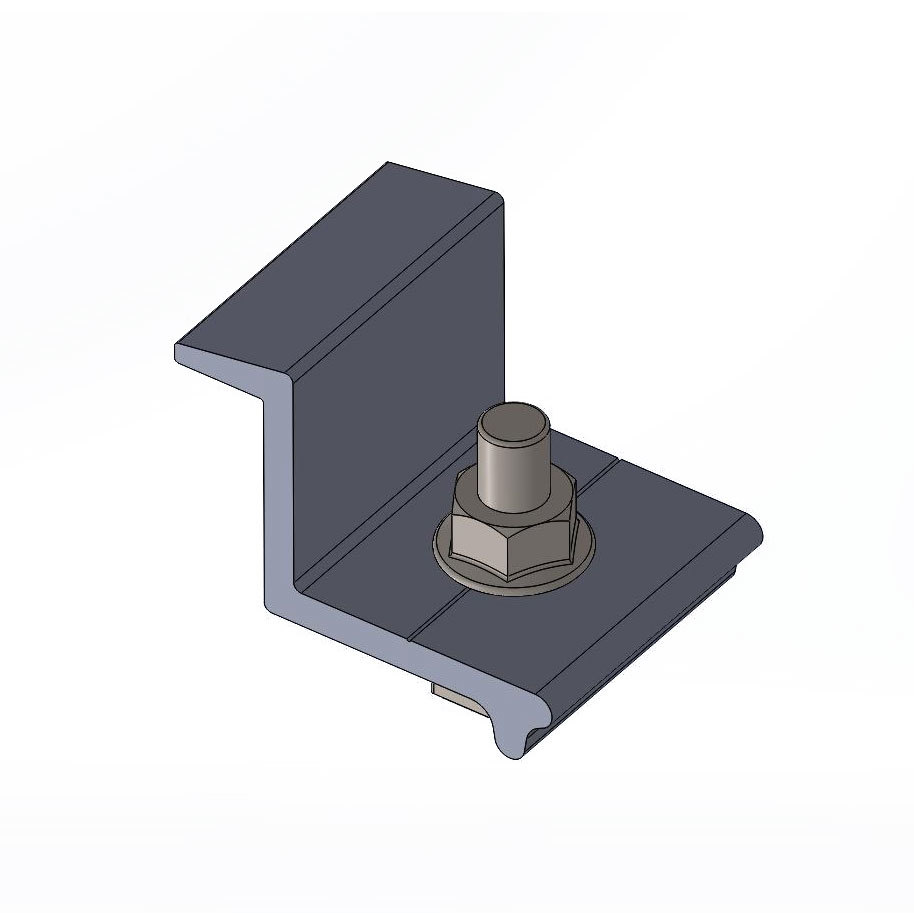

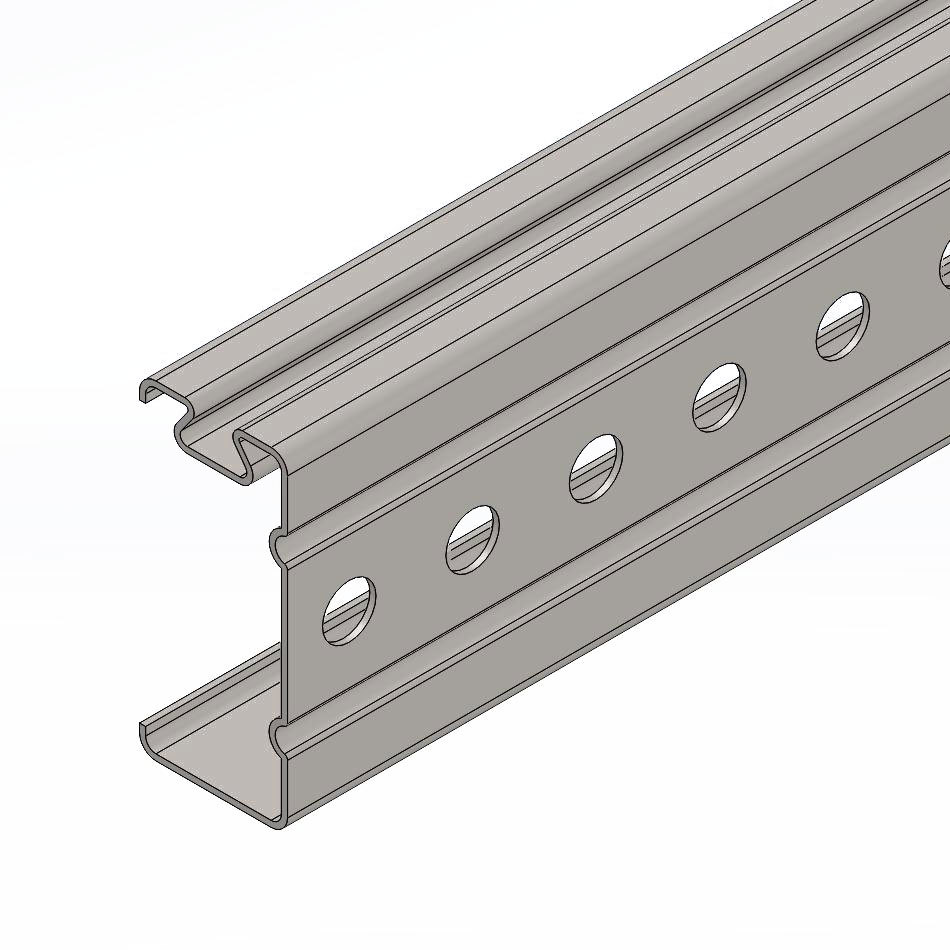

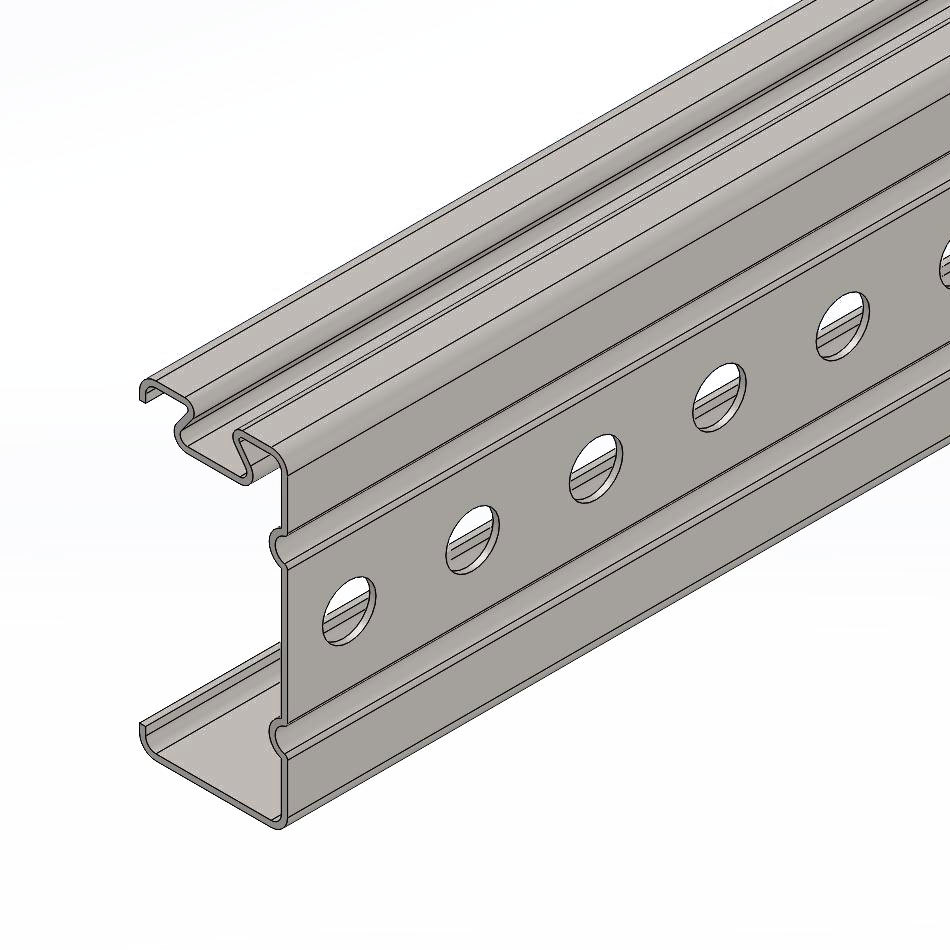

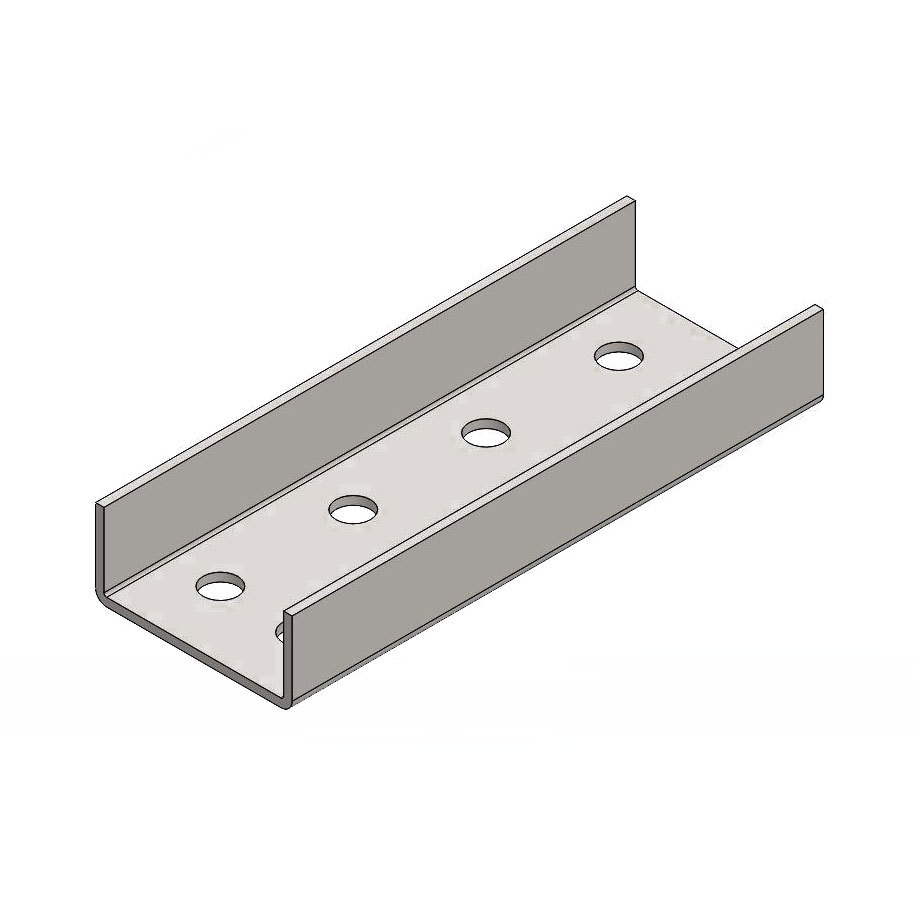

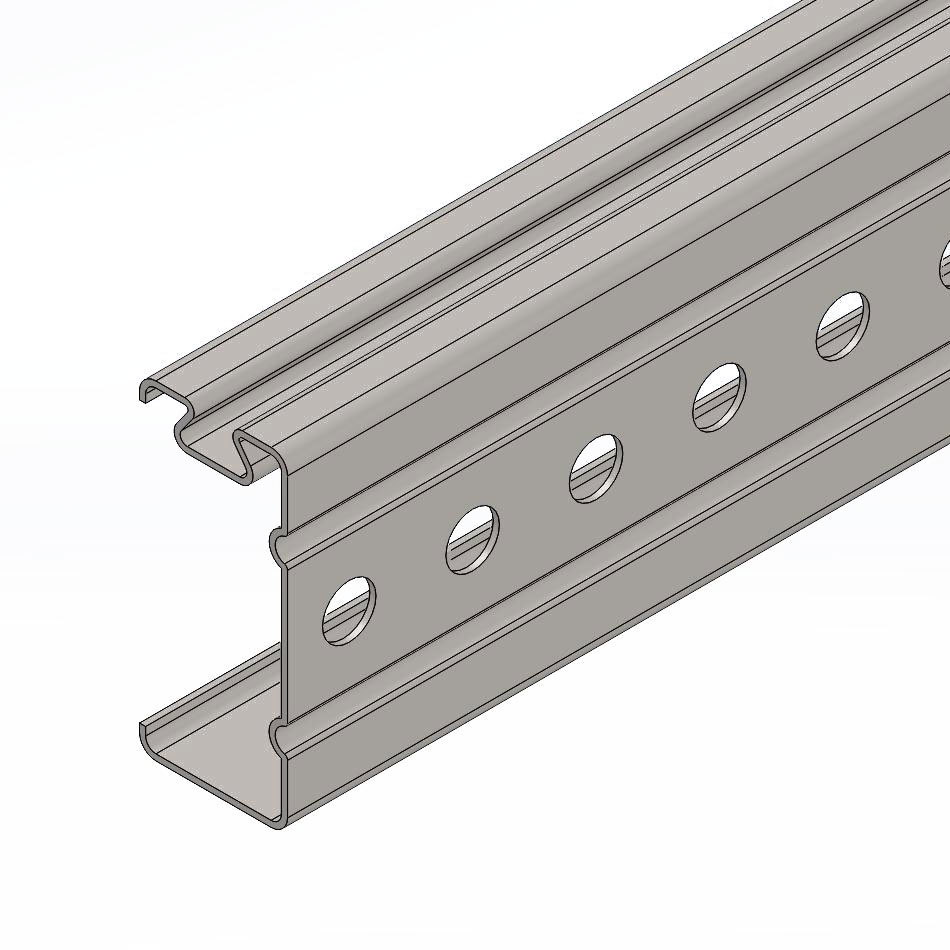

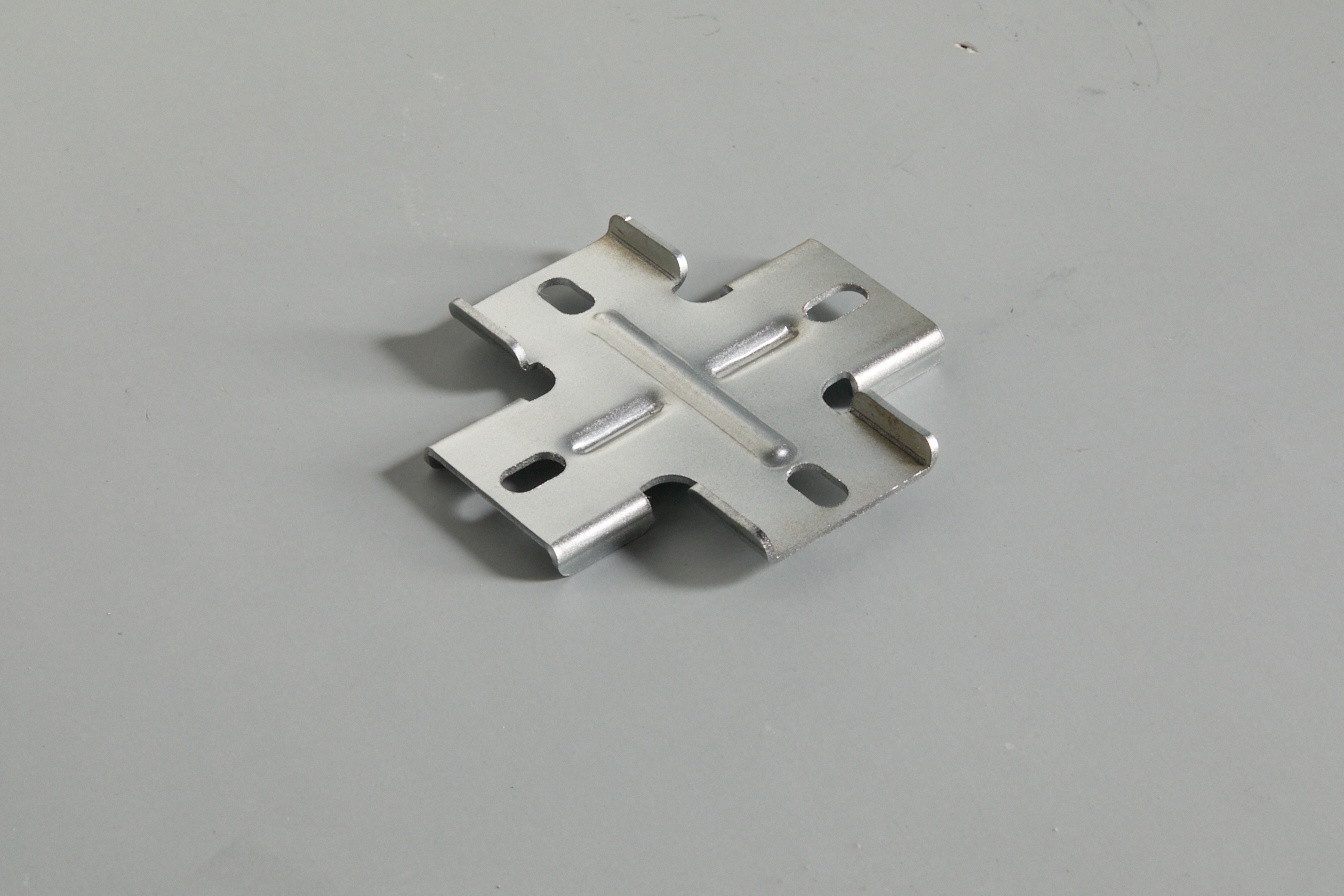

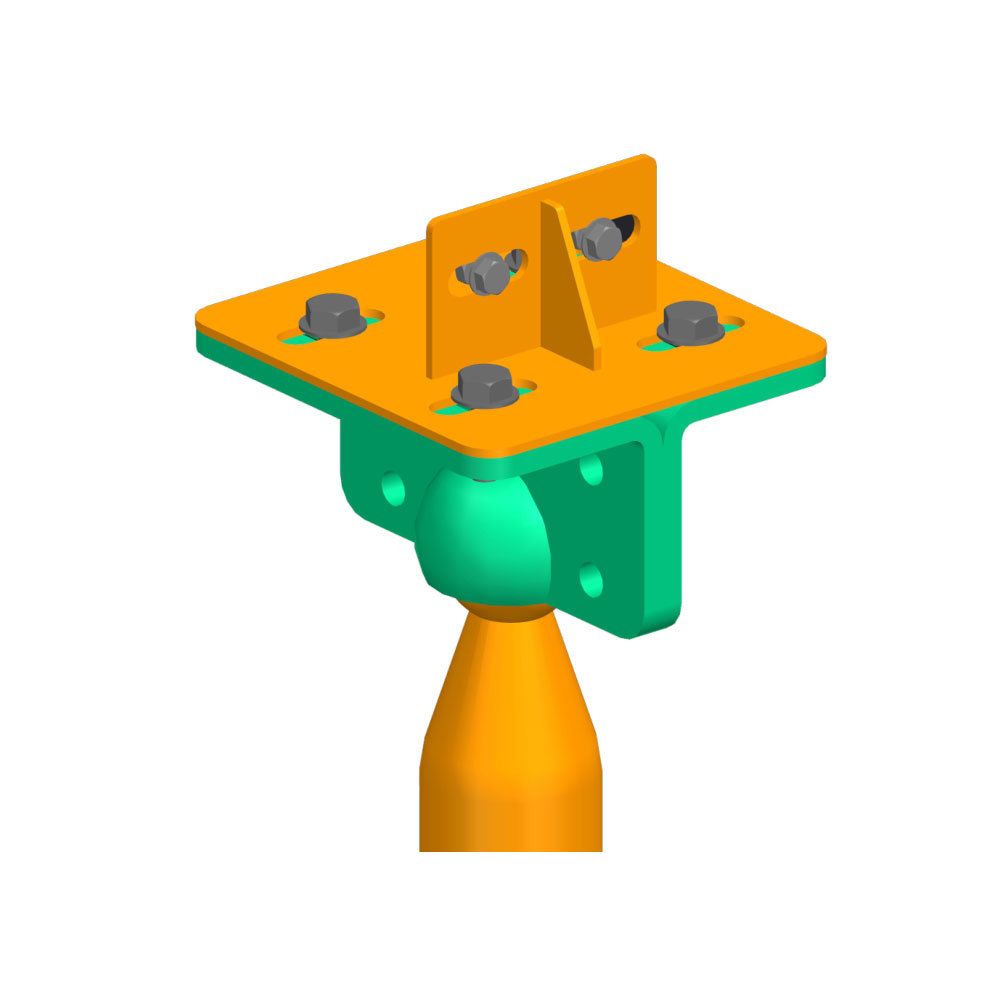

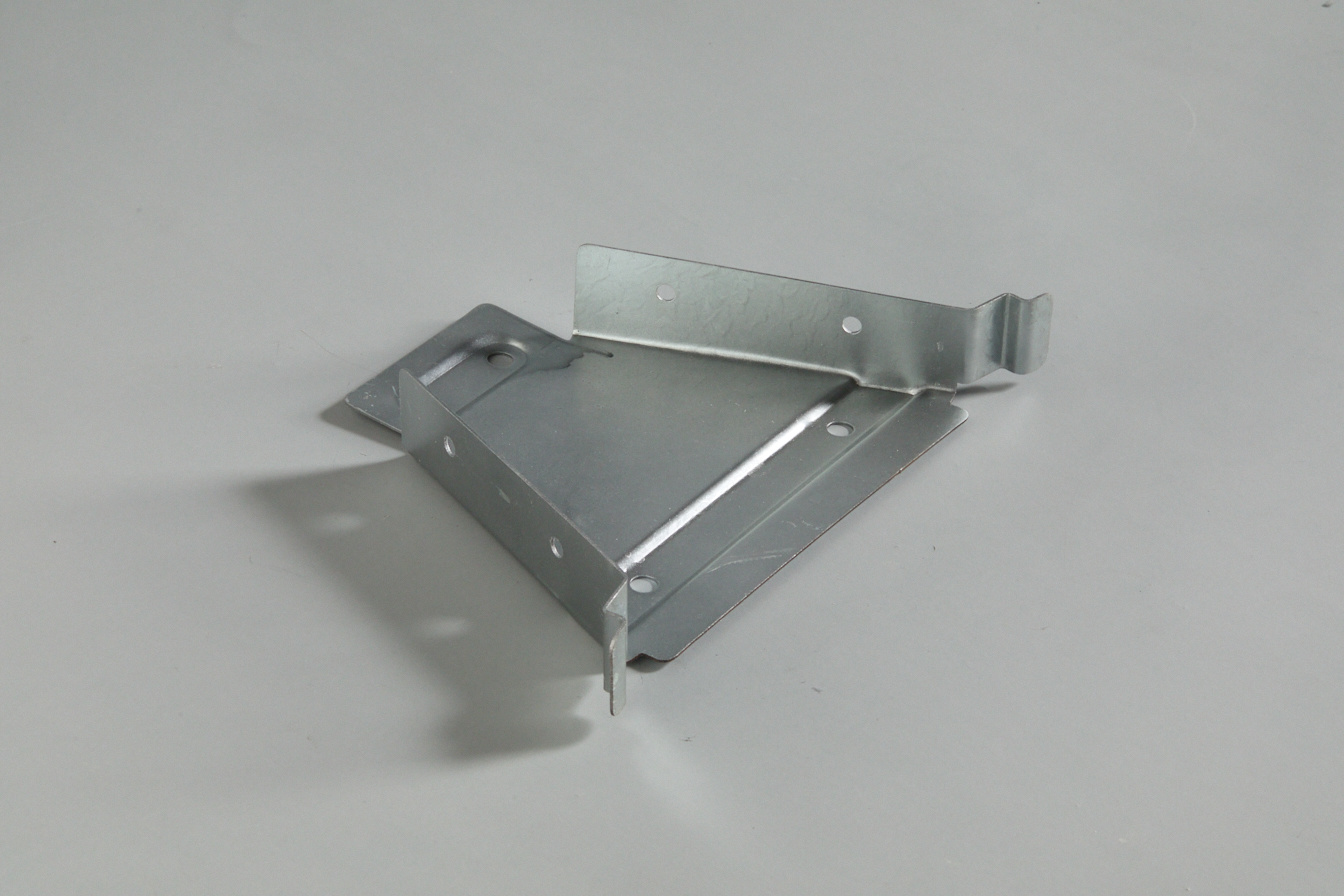

The quality 153 inner flipped edge refers to a specialized forming process where the inner edge of a component is precisely flipped or bent inward to enhance overall structural stability. This feature not only improves mechanical resistance but also reduces risks of cracks, deformation, or failure under high stress. For industries where safety and reliability are critical, this advancement is a significant breakthrough.

Key Highlights for Industry Clients:

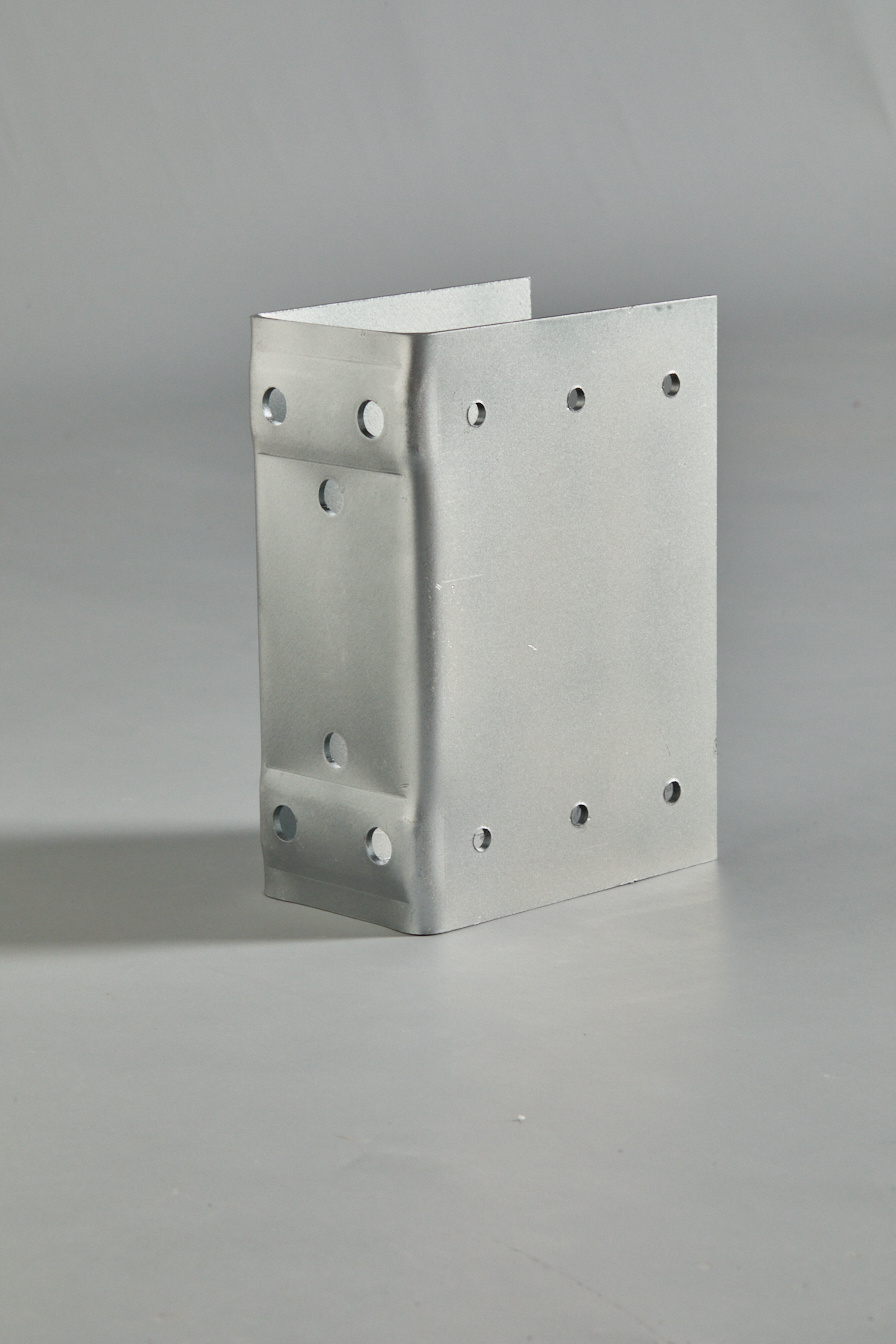

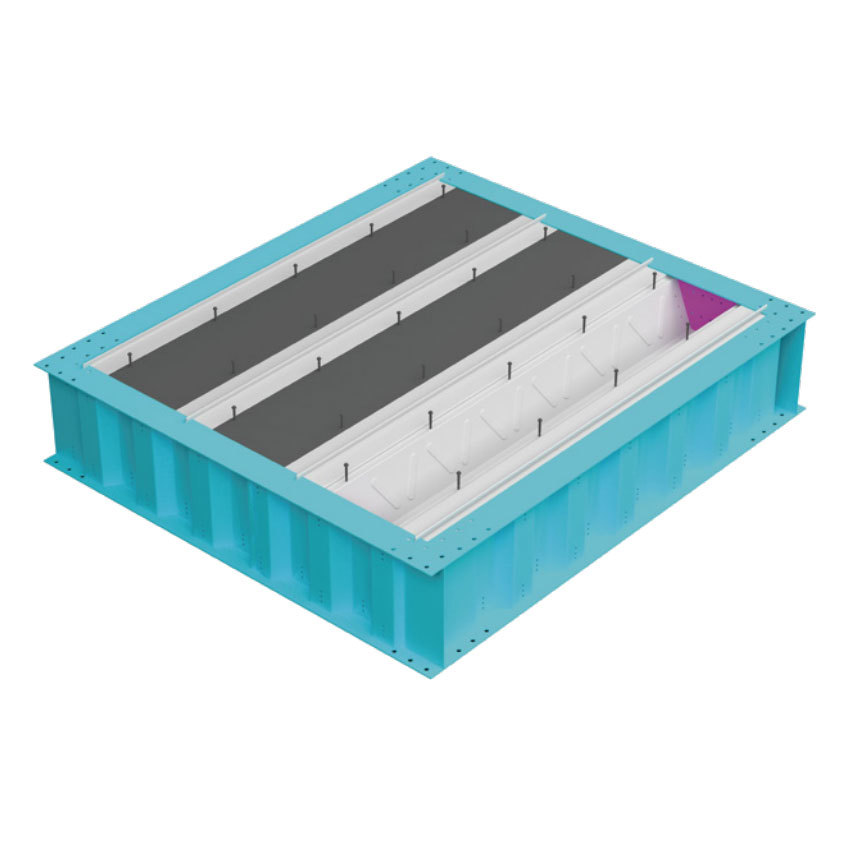

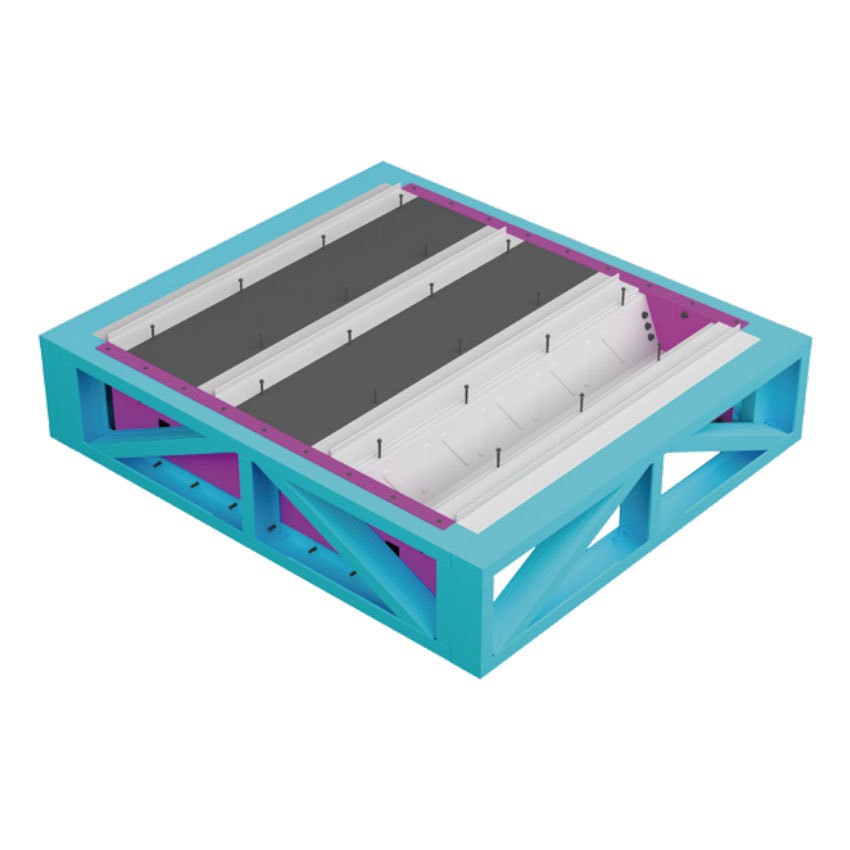

Enhanced Strength & Safety: The inner flipped edge reinforces critical parts, ensuring excellent load-bearing capacity, ideal for automotive body frames, aerospace panels, and rail transit components.

Precision Manufacturing: The “quality 153” standard emphasizes high dimensional accuracy, minimizing defects during assembly and guaranteeing compatibility across large-scale production lines.

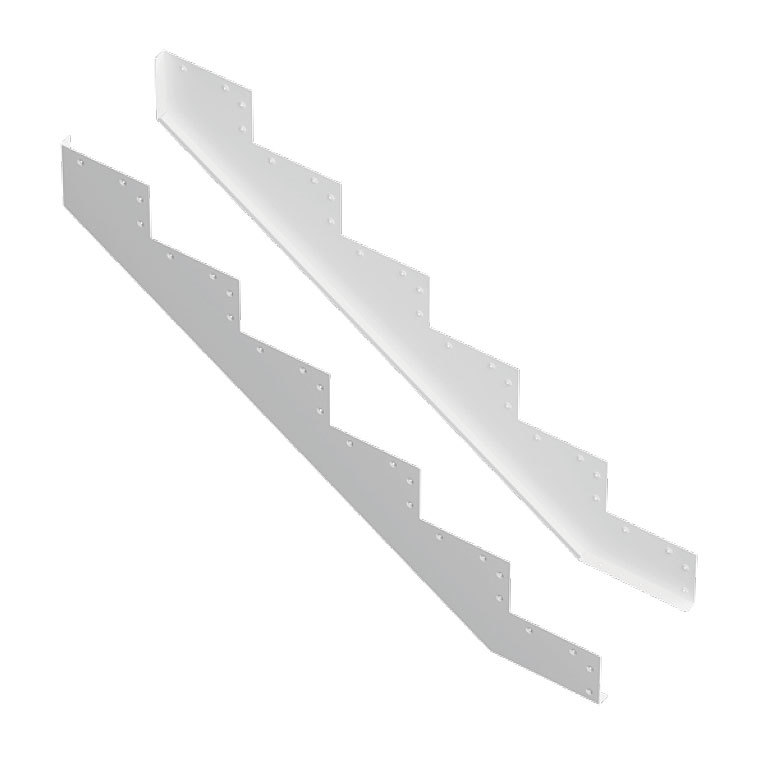

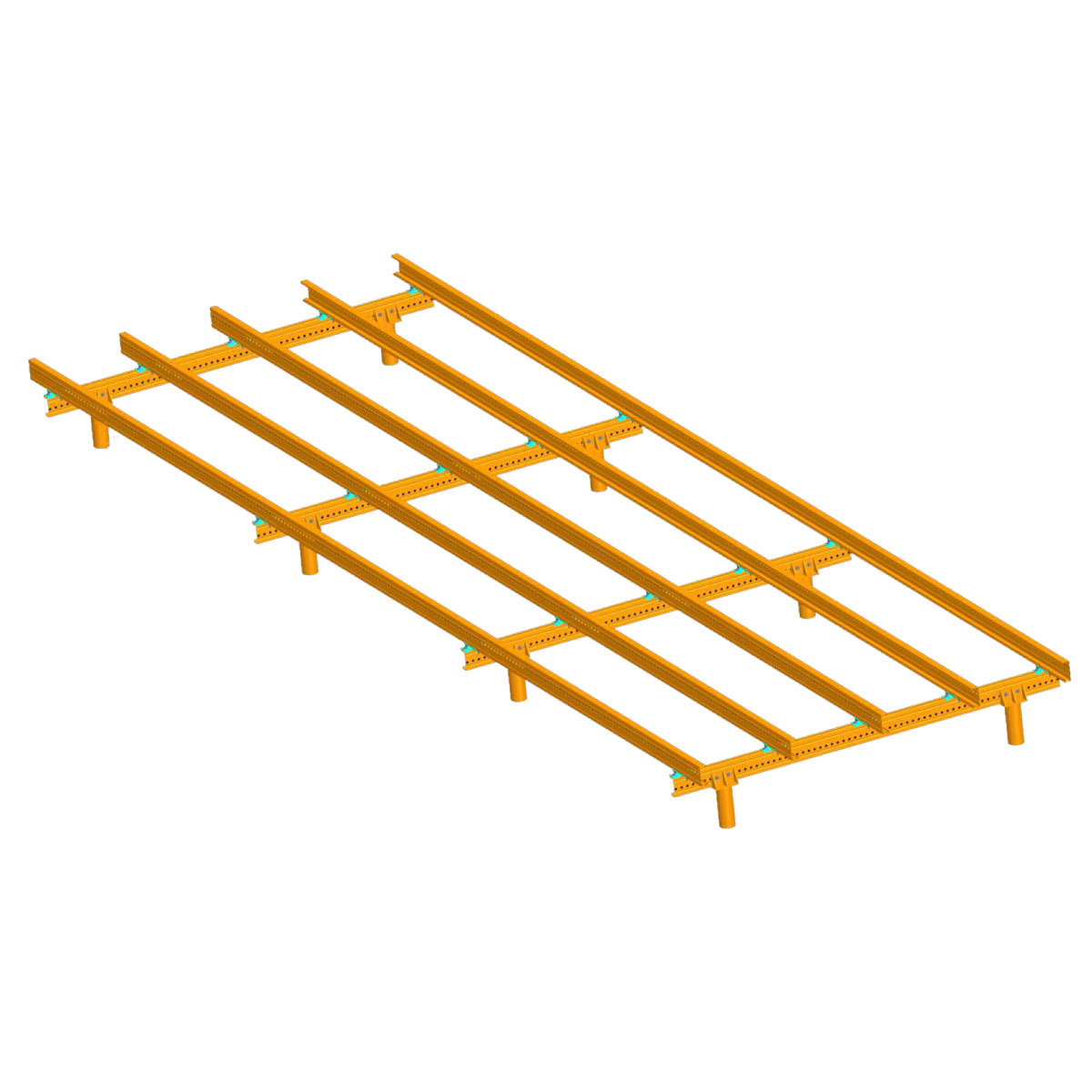

Cost-Efficiency in Production: By reducing the need for secondary reinforcement, this technology lowers material waste and shortens processing time—directly benefiting manufacturers seeking lean production.

Extended Service Life: Components designed with the inner flipped edge show superior fatigue resistance, making them highly reliable for high-vibration or high-temperature applications.

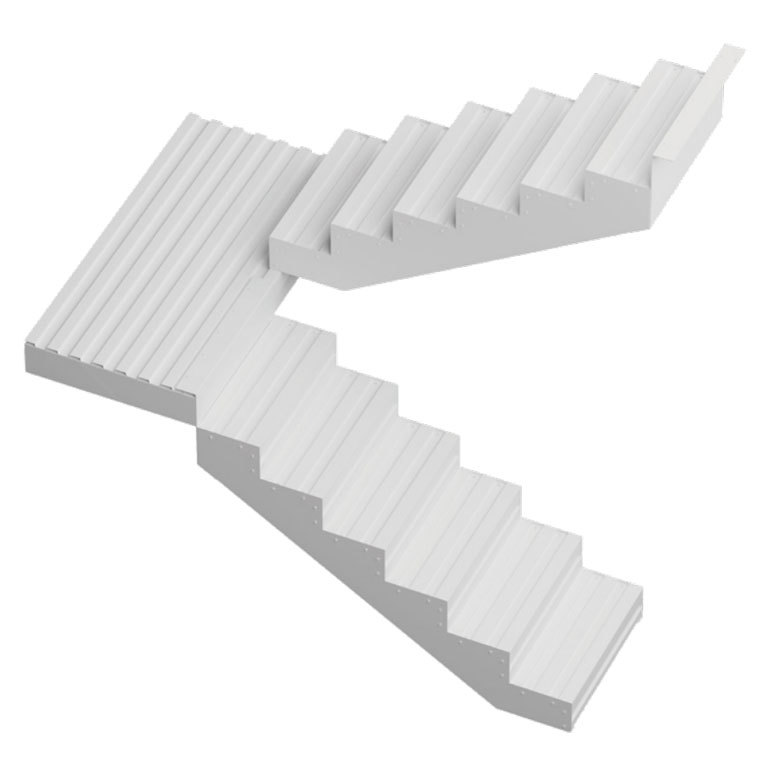

Industry experts point out that quality 153 inner flipped edge products are increasingly in demand for lightweight design solutions, particularly in the automotive and aerospace sectors, where balancing strength and reduced weight is essential for fuel efficiency and carbon reduction goals. Manufacturers adopting this technology are not only enhancing product durability but also responding to global sustainability trends.

Companies at the forefront of this innovation are already integrating quality 153 inner flipped edge designs into customized solutions for OEMs, offering clients greater flexibility in meeting stringent international standards. For clients in automotive stamping, aerospace fabrication, and industrial equipment manufacturing, the adoption of this edge design is no longer an option but a necessity to stay competitive.

As the market evolves, the quality 153 inner flipped edge is expected to become a widely recognized benchmark in high-precision engineering, ensuring that manufacturers achieve optimal balance between safety, efficiency, and cost-effectiveness.

Related Information

HaoHeng Group

Address: Room 1808, Block A, Vanke Cloud City, Jiemei District, Xiamen City, Fujian Province

Business cooperation:

Copyright © HaoHeng (FuJian) Building Materials Technology Co, Ltd. All rights reserved