Understanding the Functionality of T-Shaped Column Connectors: A Comprehensive Guide

Release Time:

2025-03-03

Source:

Understanding the Functionality of T-Shaped Column Connectors: A Comprehensive Guide

Table of Contents

- 1. Introduction to T-Shaped Column Connectors

- 2. Importance of T-Shaped Column Connectors in Construction

- 3. Design Considerations for T-Shaped Column Connectors

- 4. Materials Used in T-Shaped Column Connectors

- 5. Applications of T-Shaped Column Connectors

- 6. Benefits of Using T-Shaped Column Connectors

- 7. Installation Guidelines for T-Shaped Column Connectors

- 8. Maintenance and Inspection of T-Shaped Column Connectors

- 9. Conclusion

- 10. Frequently Asked Questions (FAQs)

1. Introduction to T-Shaped Column Connectors

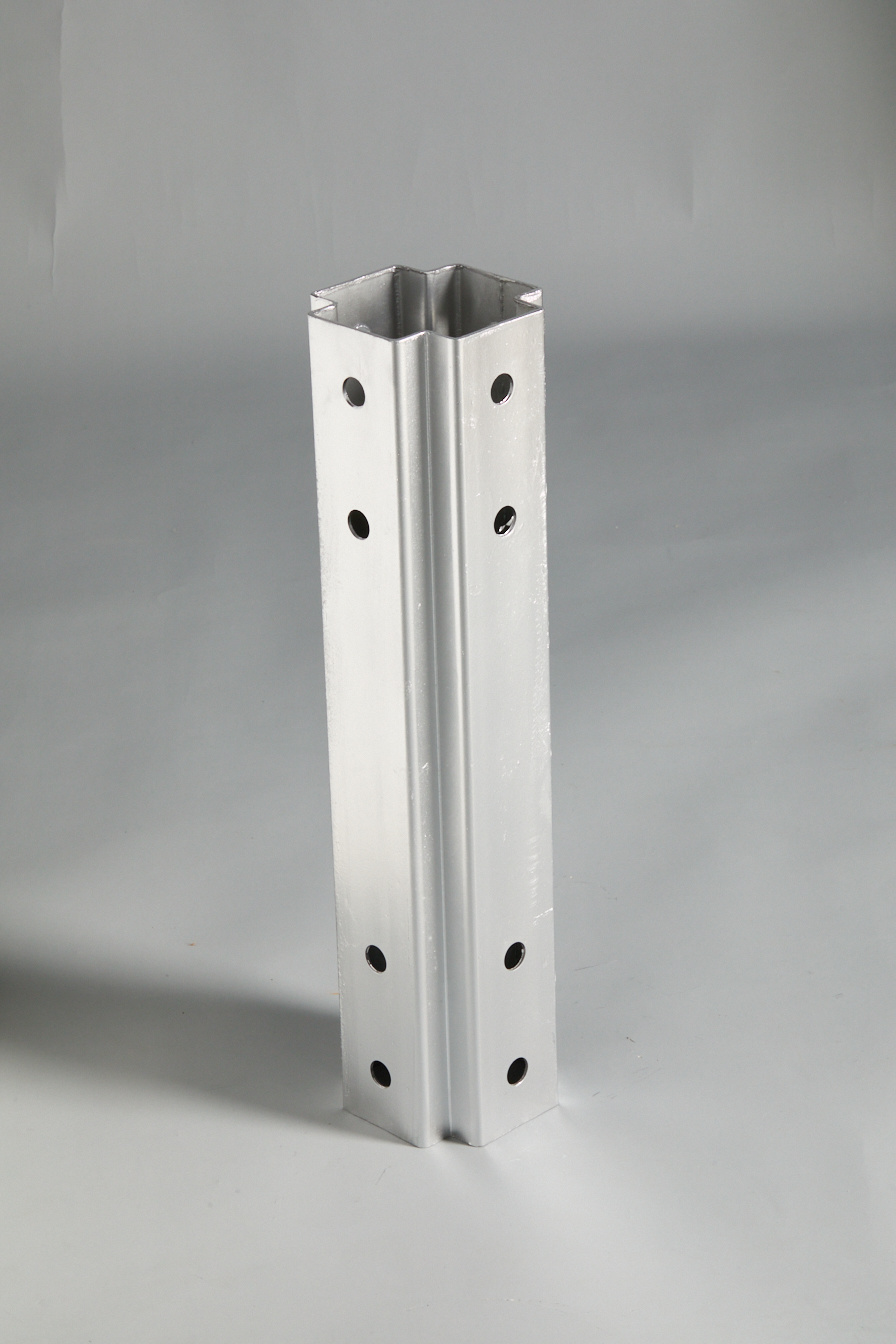

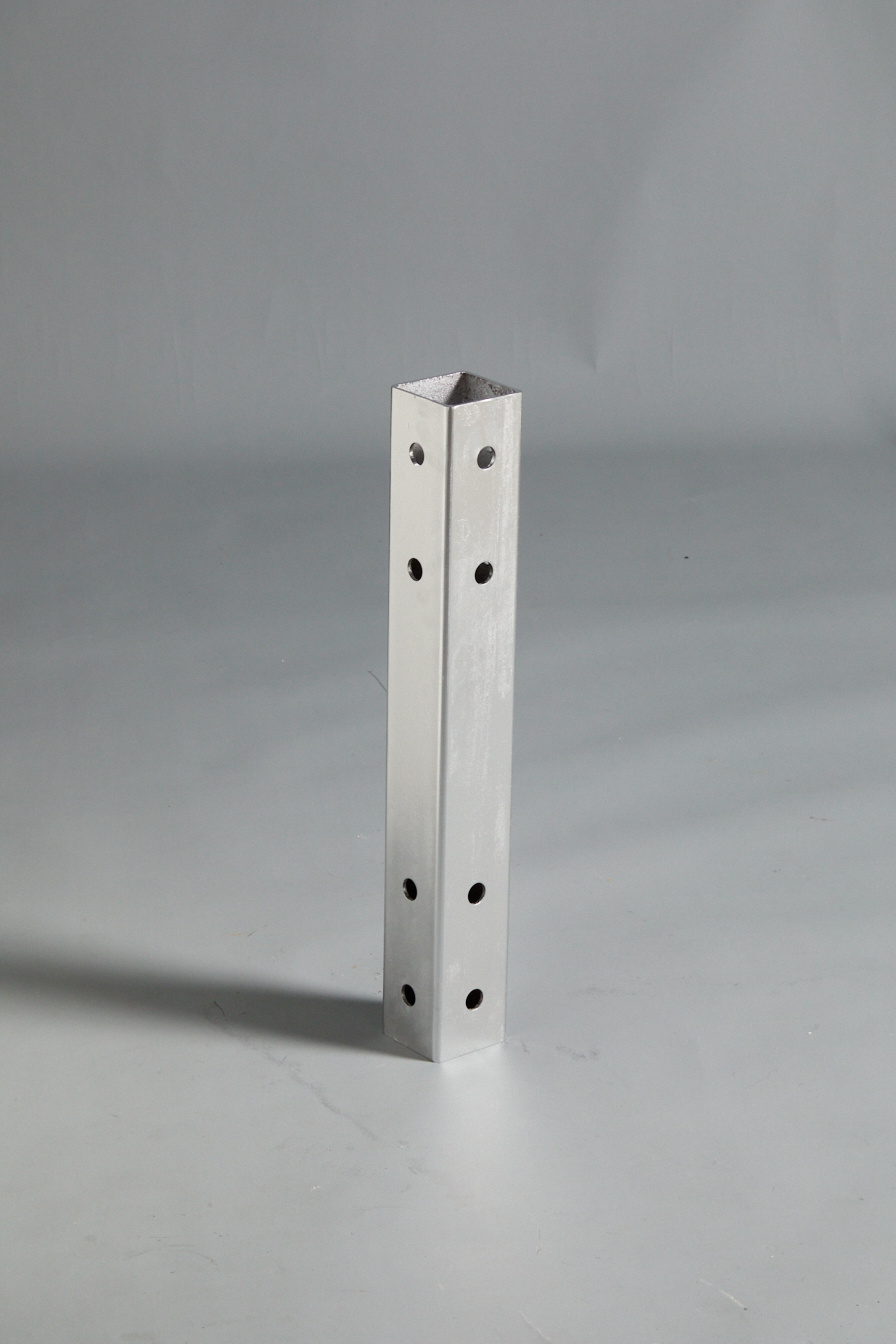

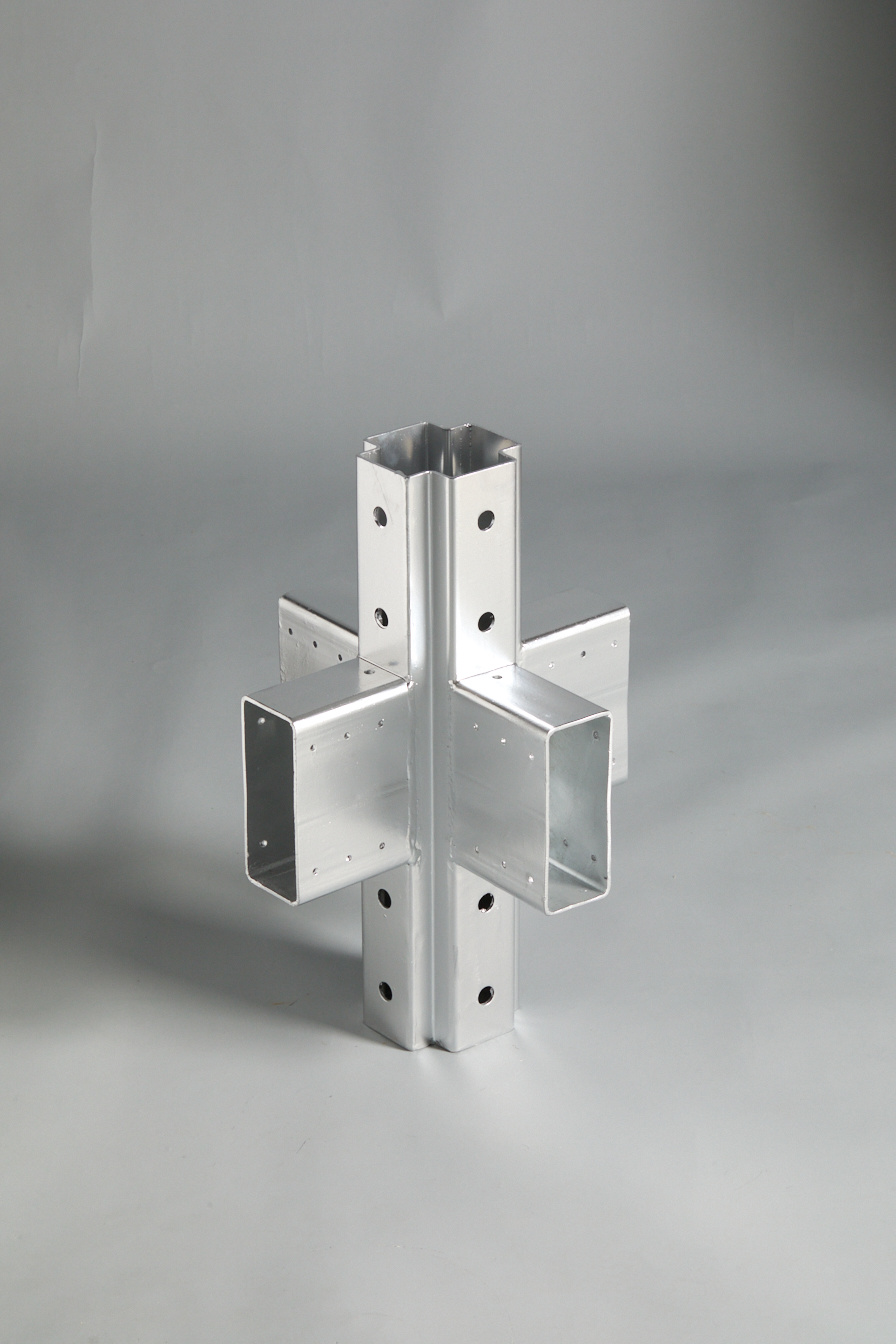

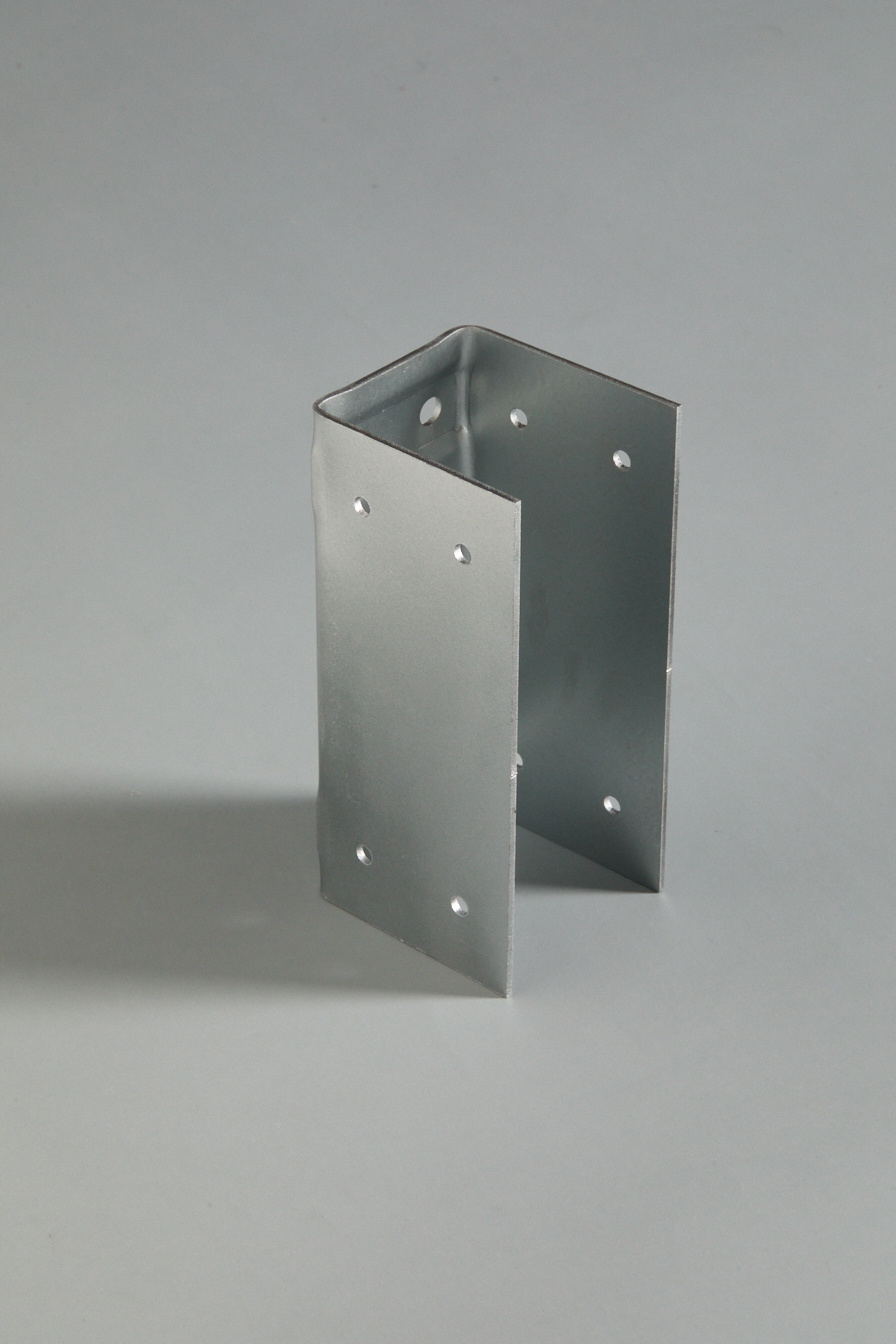

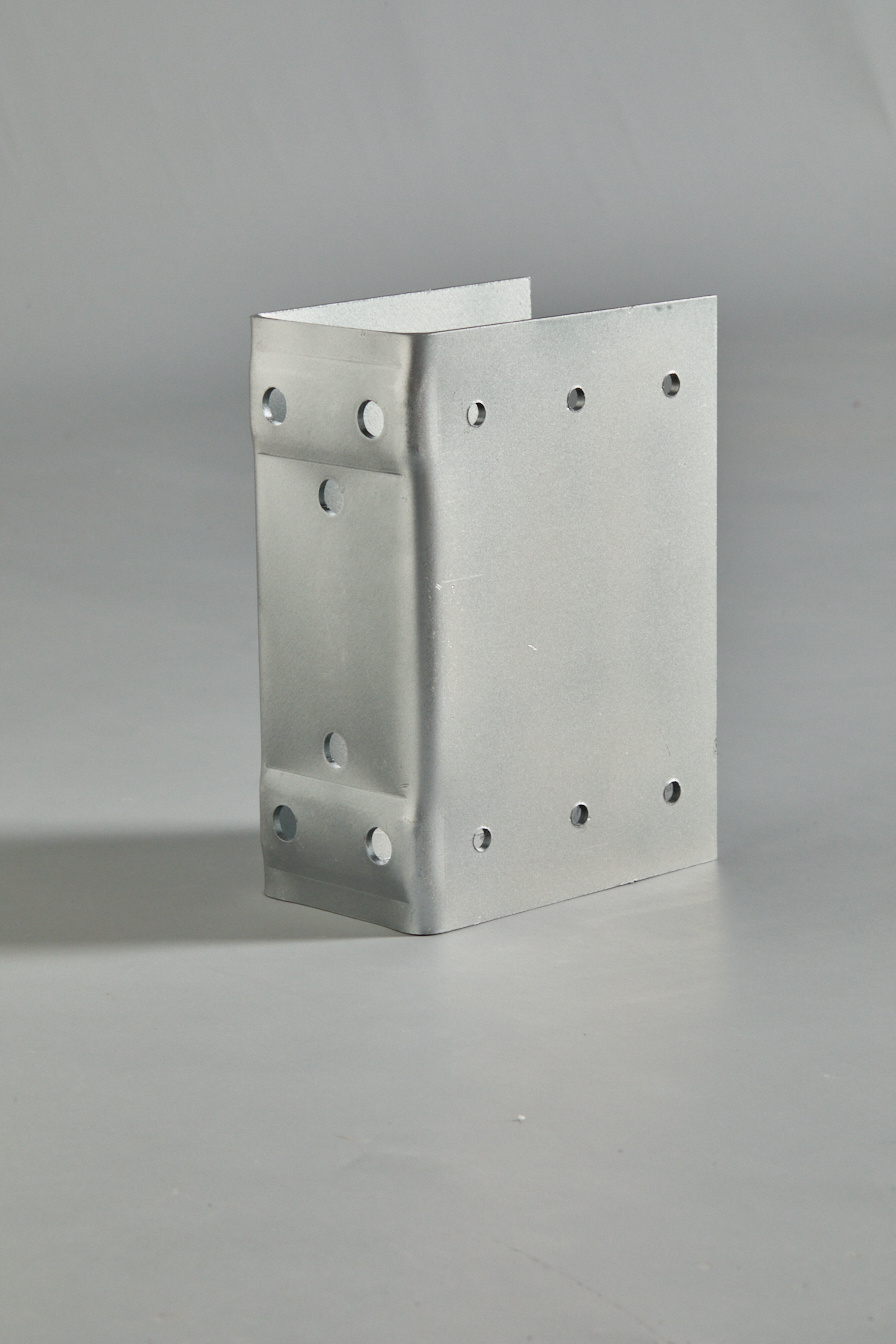

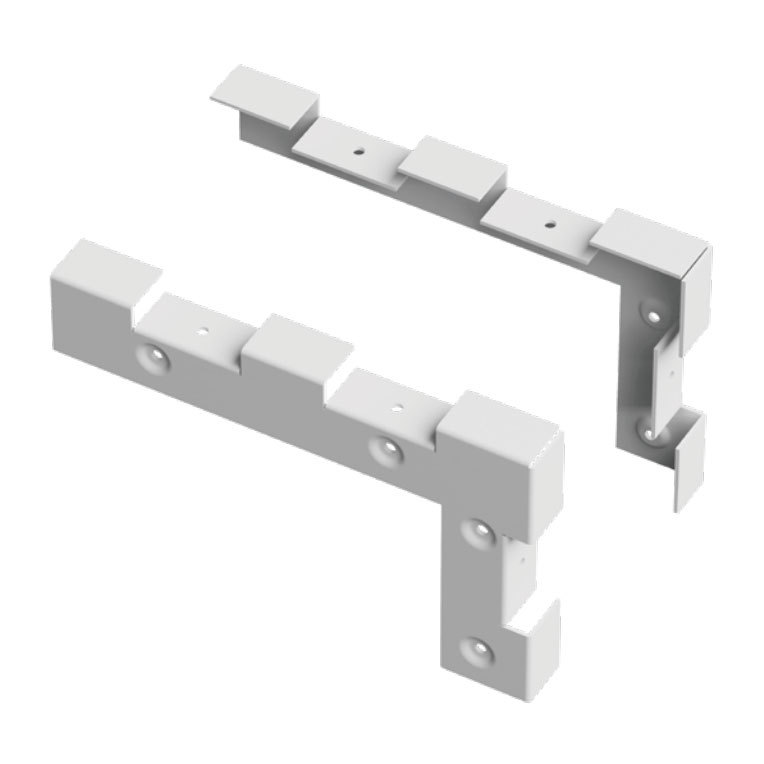

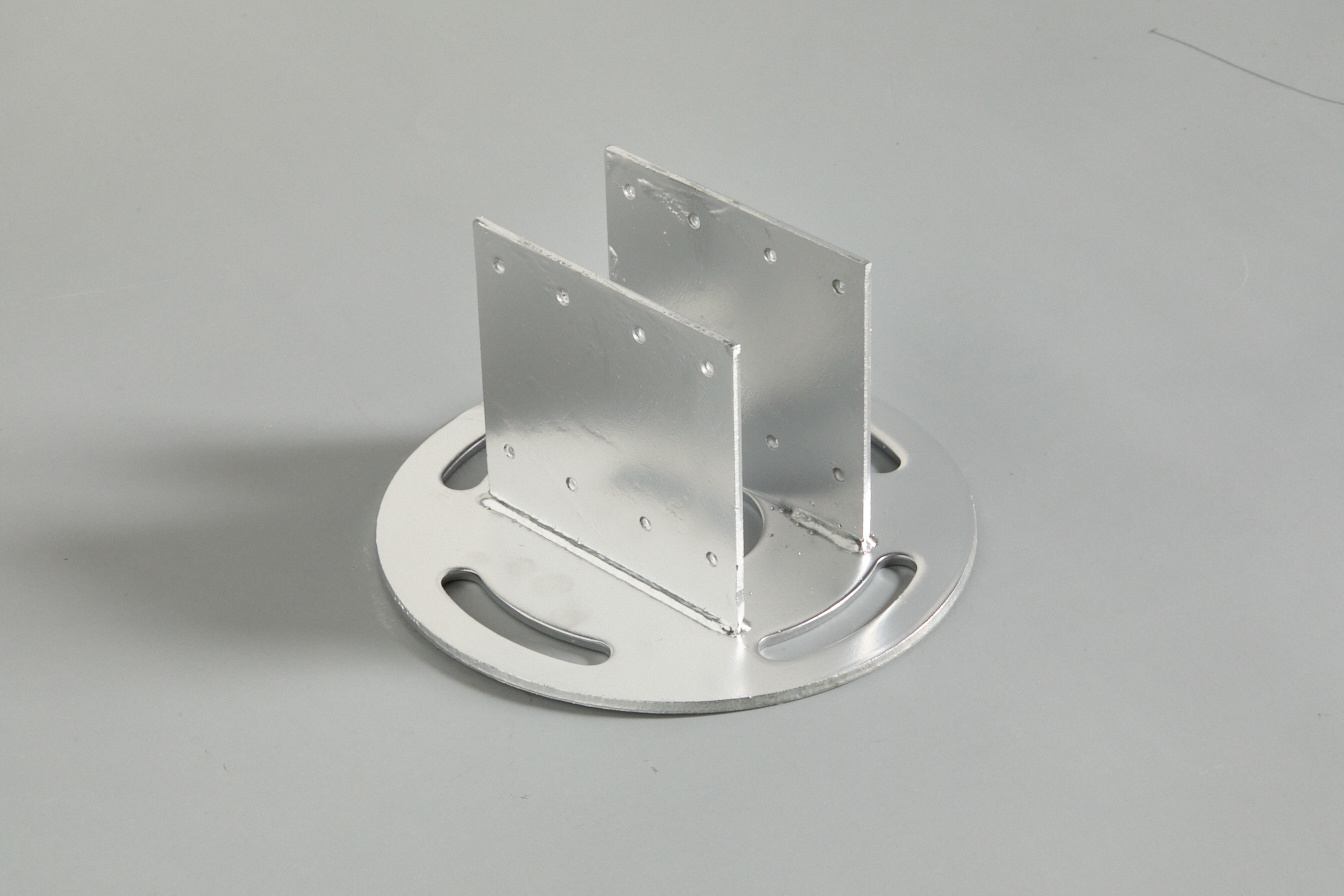

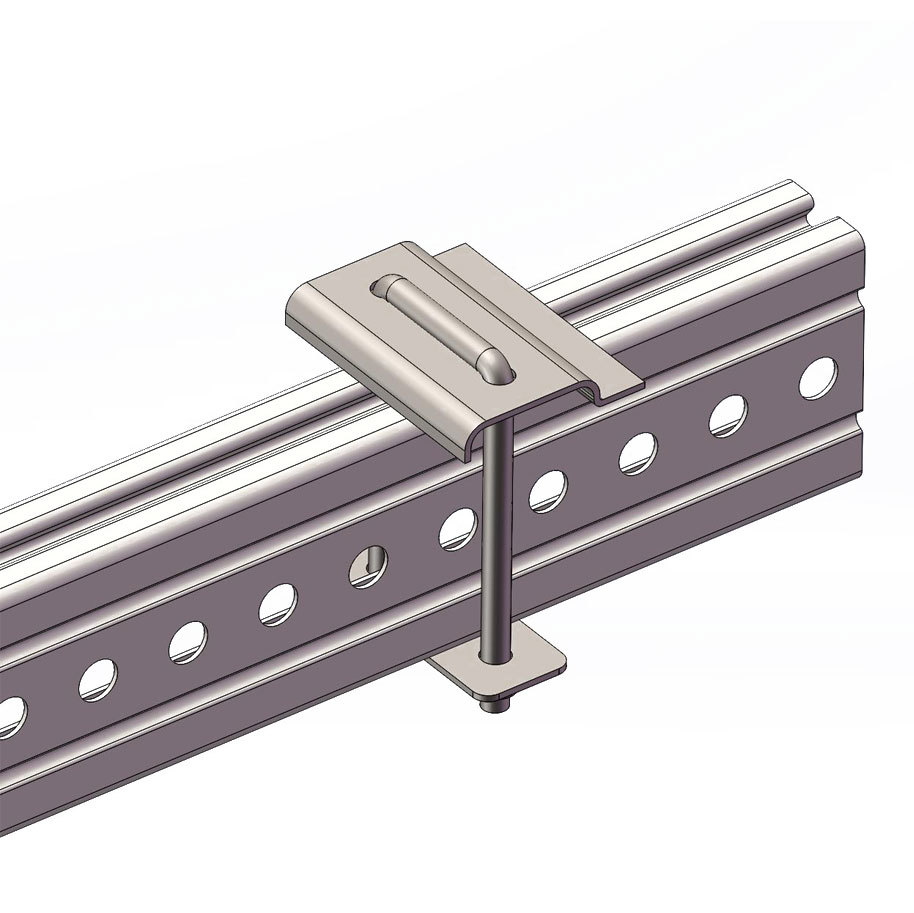

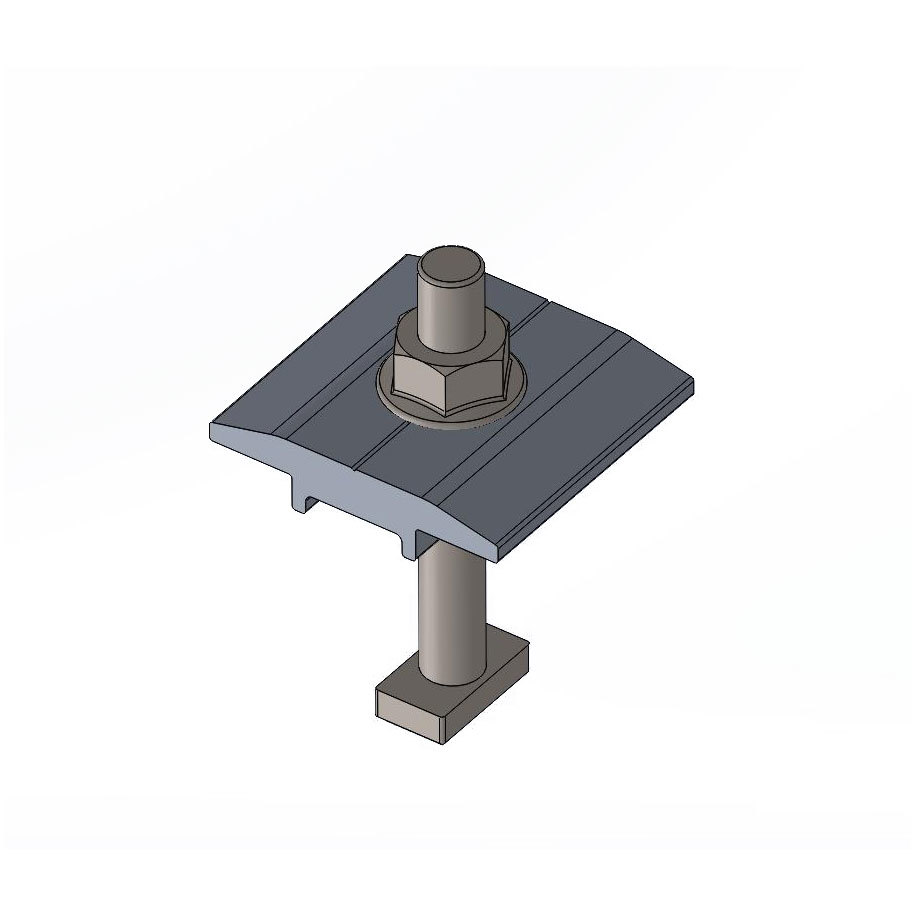

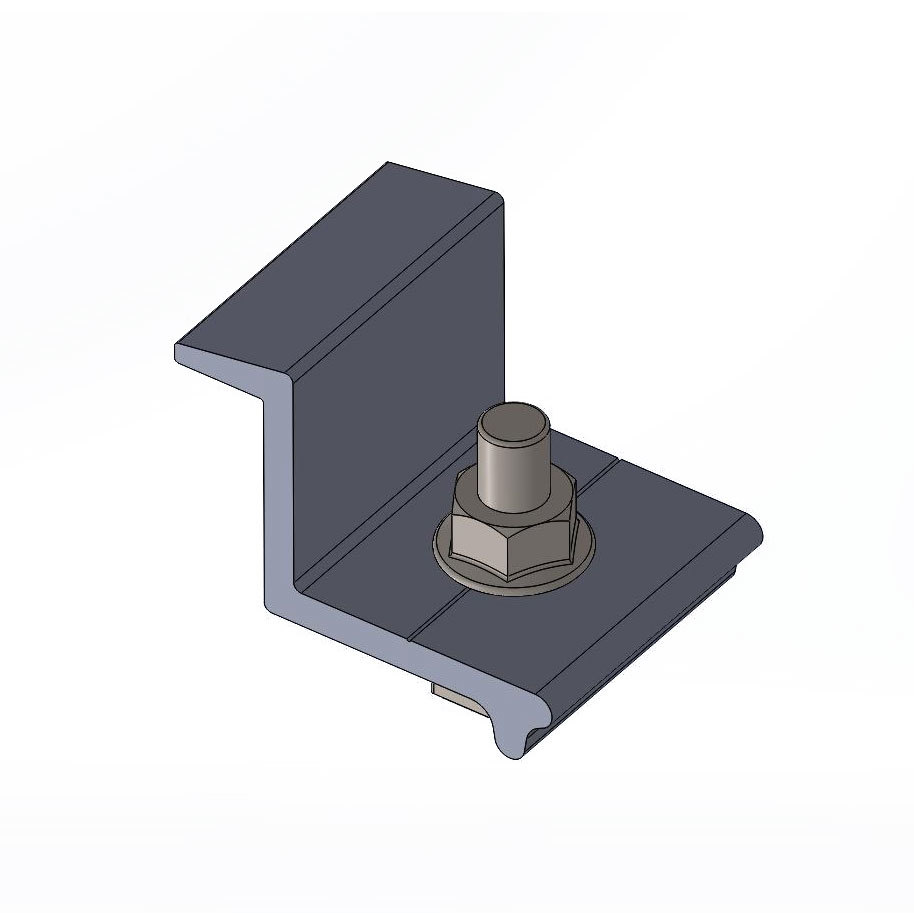

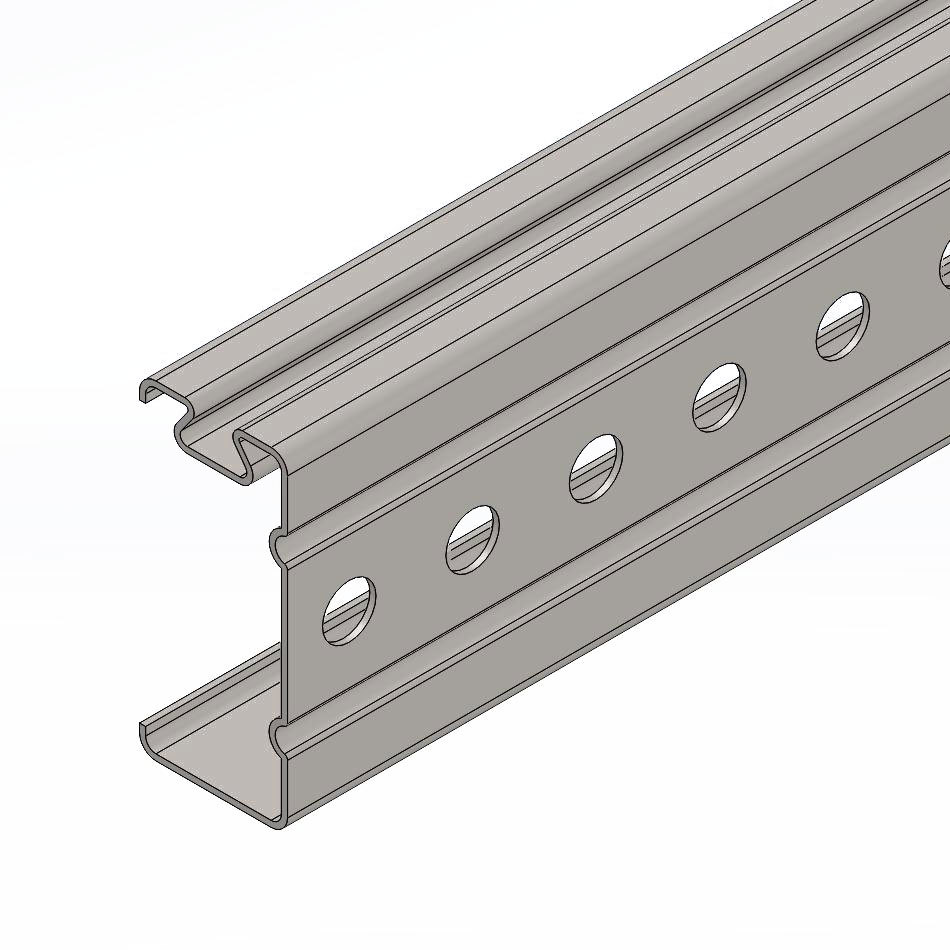

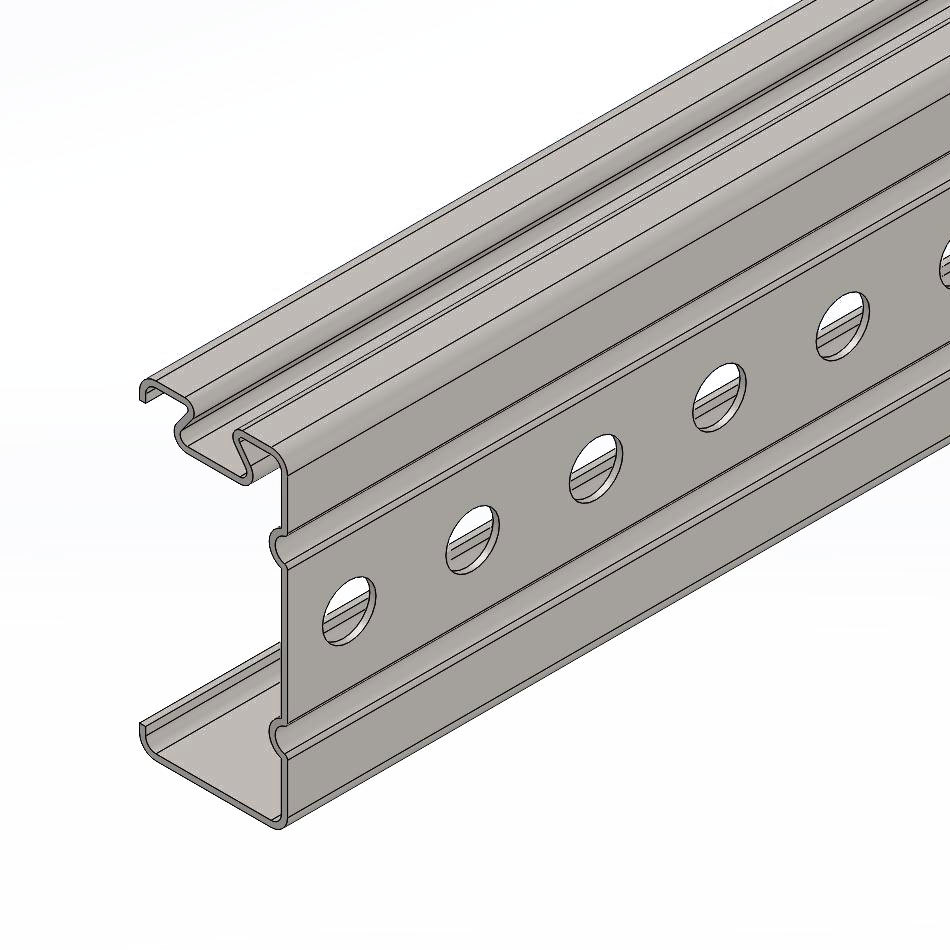

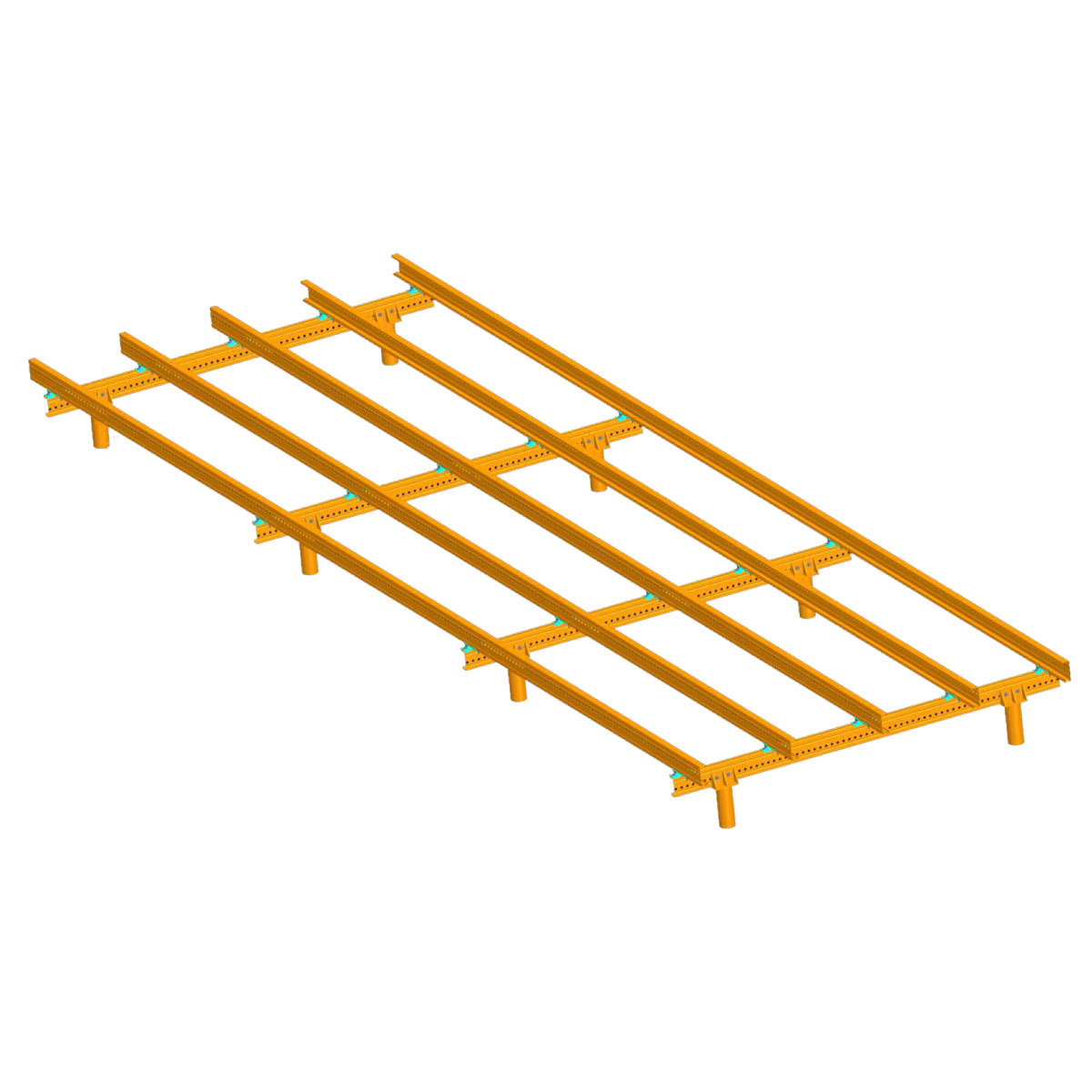

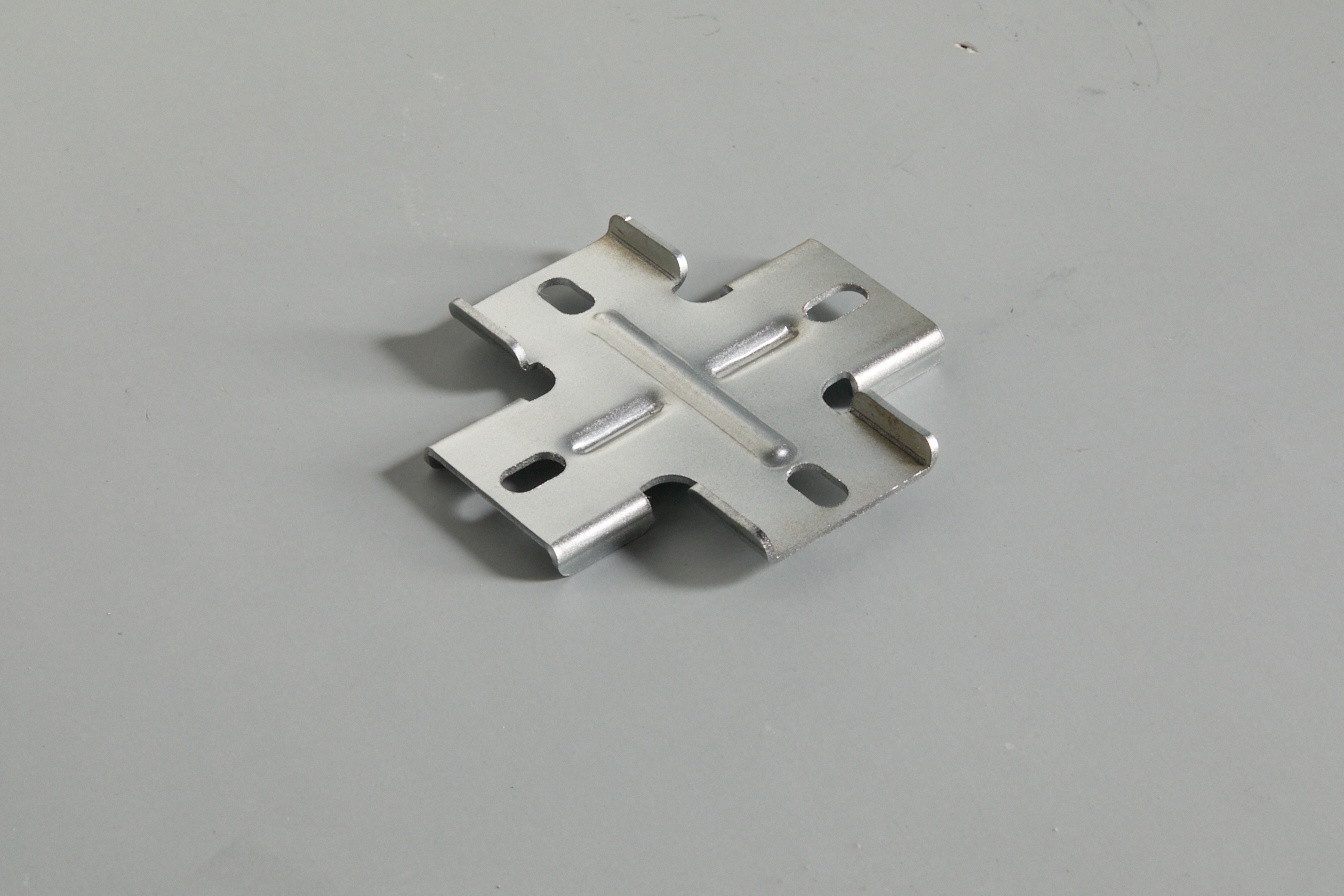

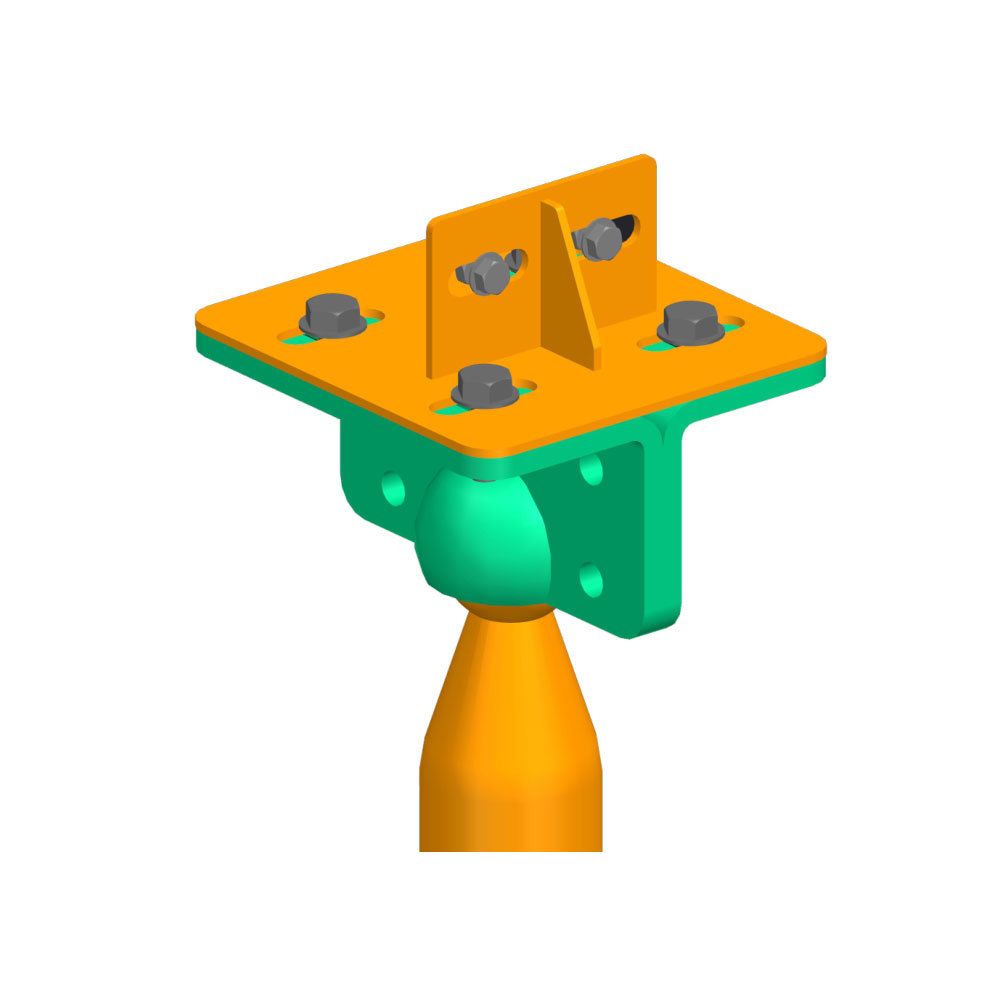

T-shaped column connectors are essential components in modern construction, facilitating the joining of vertical and horizontal structural elements. These connectors play a pivotal role in ensuring the stability and strength of buildings, bridges, and other architectural structures. By providing a robust connection between columns and beams, T-shaped connectors enhance load distribution and structural performance.

2. Importance of T-Shaped Column Connectors in Construction

Understanding the importance of T-shaped column connectors is crucial for architects and engineers. They not only provide mechanical strength and support but also help in the aesthetic integration of various building components. The functionality of these connectors can significantly impact the overall performance of a structure, ensuring safety and longevity.

2.1 Structural Integrity

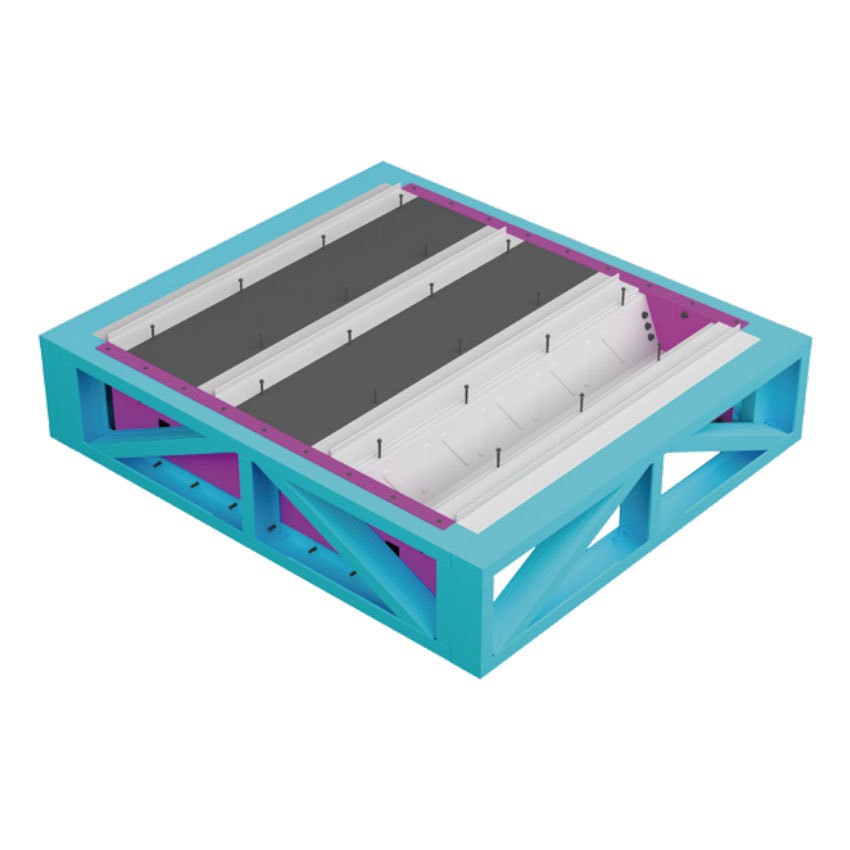

One of the primary advantages of using T-shaped column connectors is their contribution to structural integrity. They are designed to bear substantial loads, effectively transferring weight from beams to columns, thus reducing stress on individual components. This load distribution is critical, particularly in multi-story buildings where weight can accumulate significantly.

2.2 Aesthetic Appeal

T-shaped column connectors can also enhance the visual appeal of architectural designs. When employed thoughtfully, these connectors can contribute to a clean and streamlined look, integrating seamlessly with various architectural styles.

3. Design Considerations for T-Shaped Column Connectors

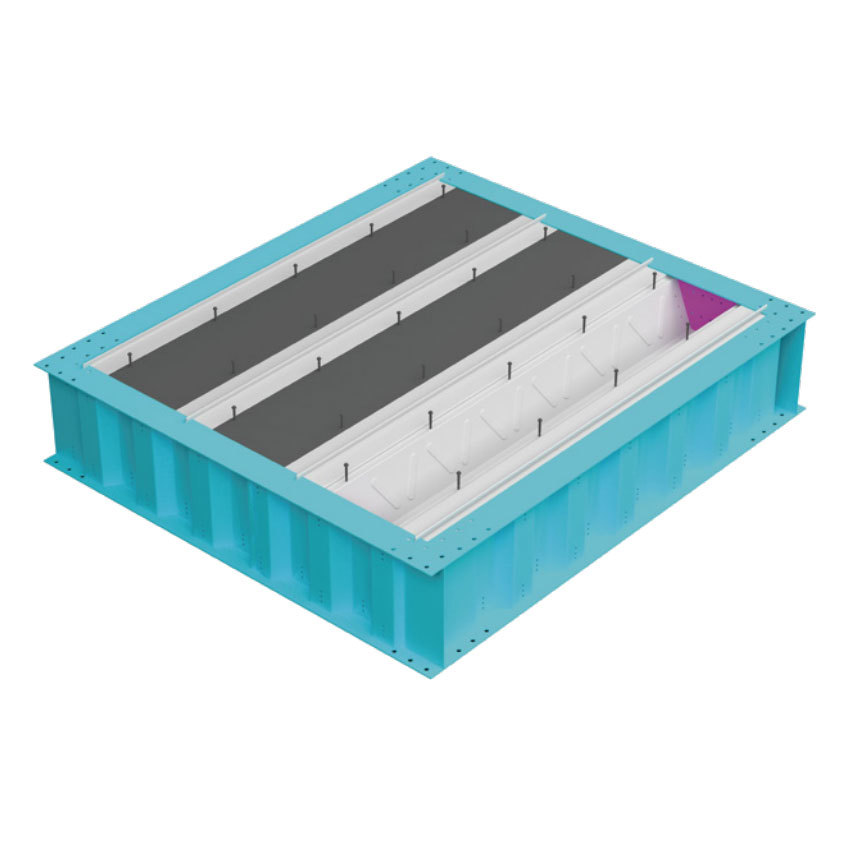

When designing T-shaped column connectors, several factors must be taken into account to ensure their effectiveness and suitability for specific applications.

3.1 Load-Bearing Capacity

The load-bearing capacity of a T-shaped column connector is a crucial design consideration. Engineers must calculate the expected loads and ensure that the connector can withstand both static and dynamic forces.

3.2 Material Selection

Choosing the right materials is fundamental to the performance of T-shaped column connectors. Different materials offer varying degrees of strength, durability, and corrosion resistance.

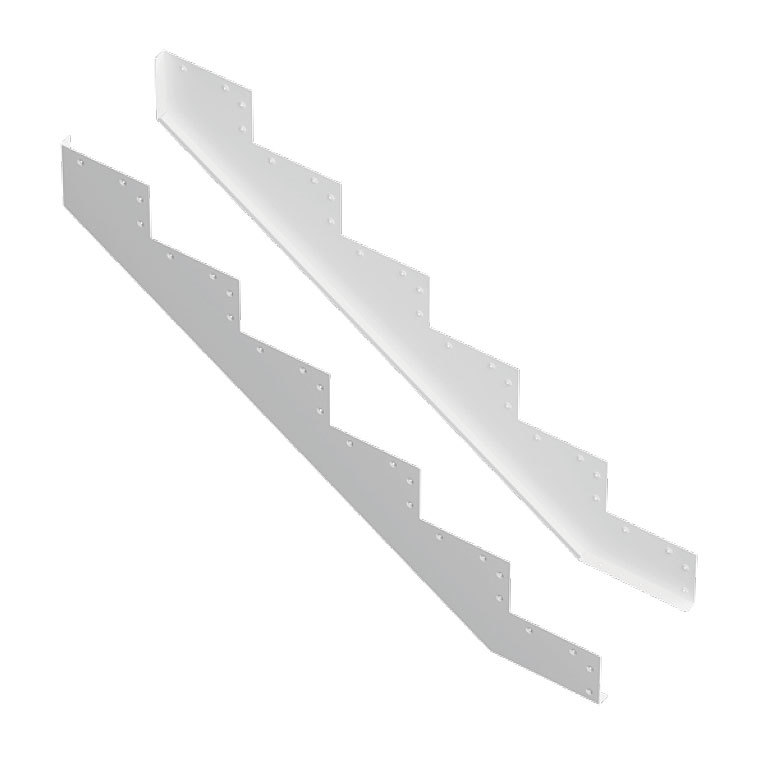

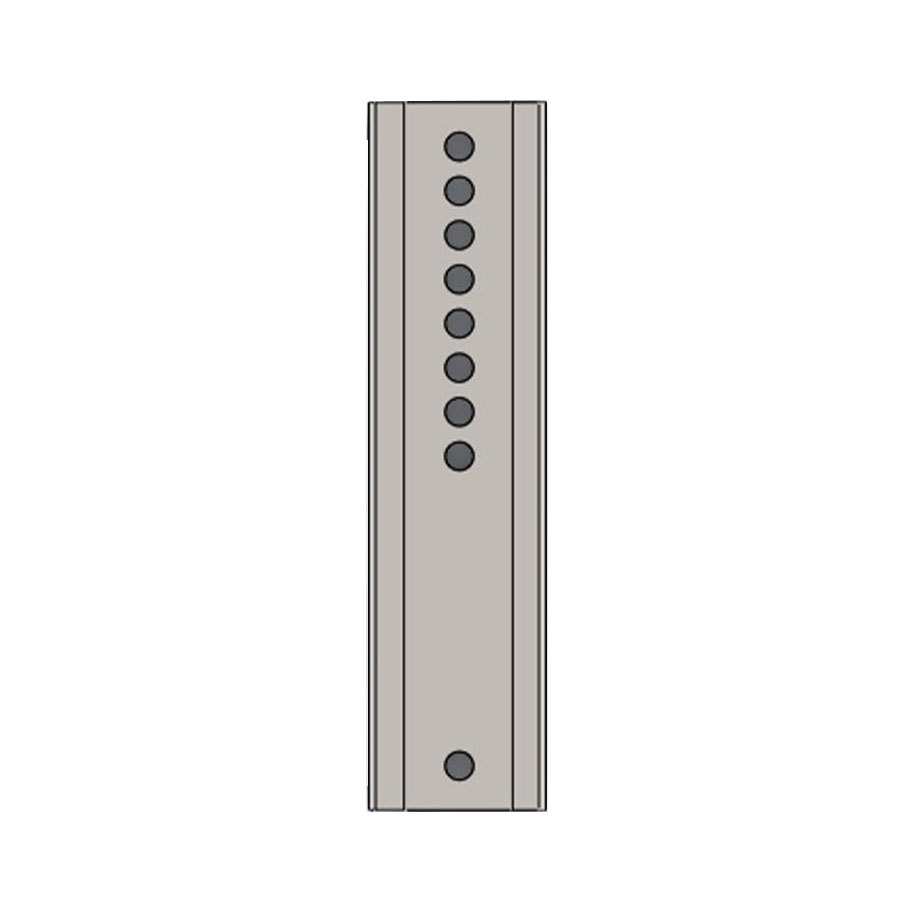

3.3 Dimensional Specifications

The dimensions of T-shaped column connectors must align with the overall design of the structure. Proper sizing ensures adequate support while maintaining the intended aesthetic.

4. Materials Used in T-Shaped Column Connectors

The materials selected for T-shaped column connectors greatly influence their functionality and longevity.

4.1 Steel

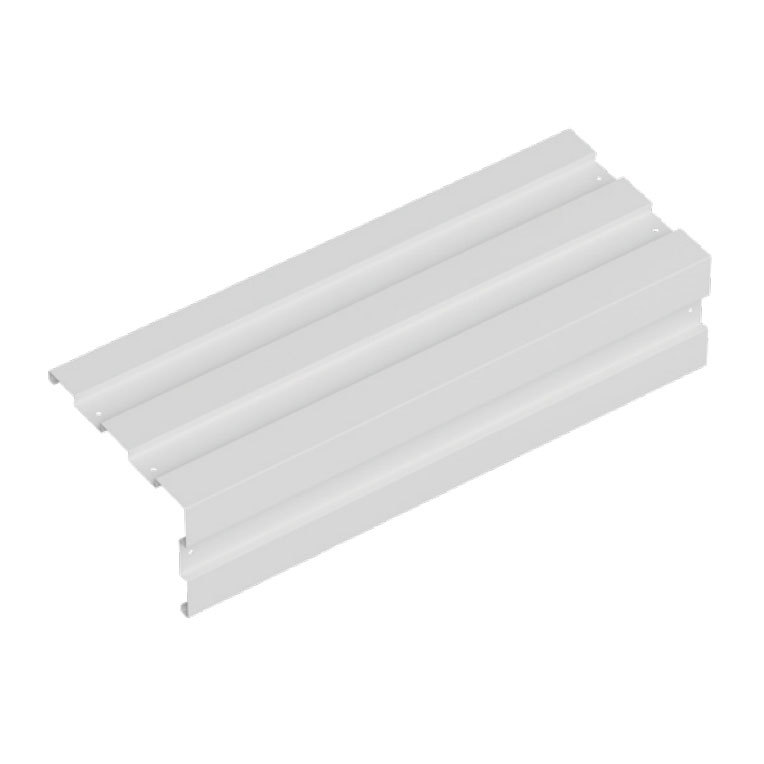

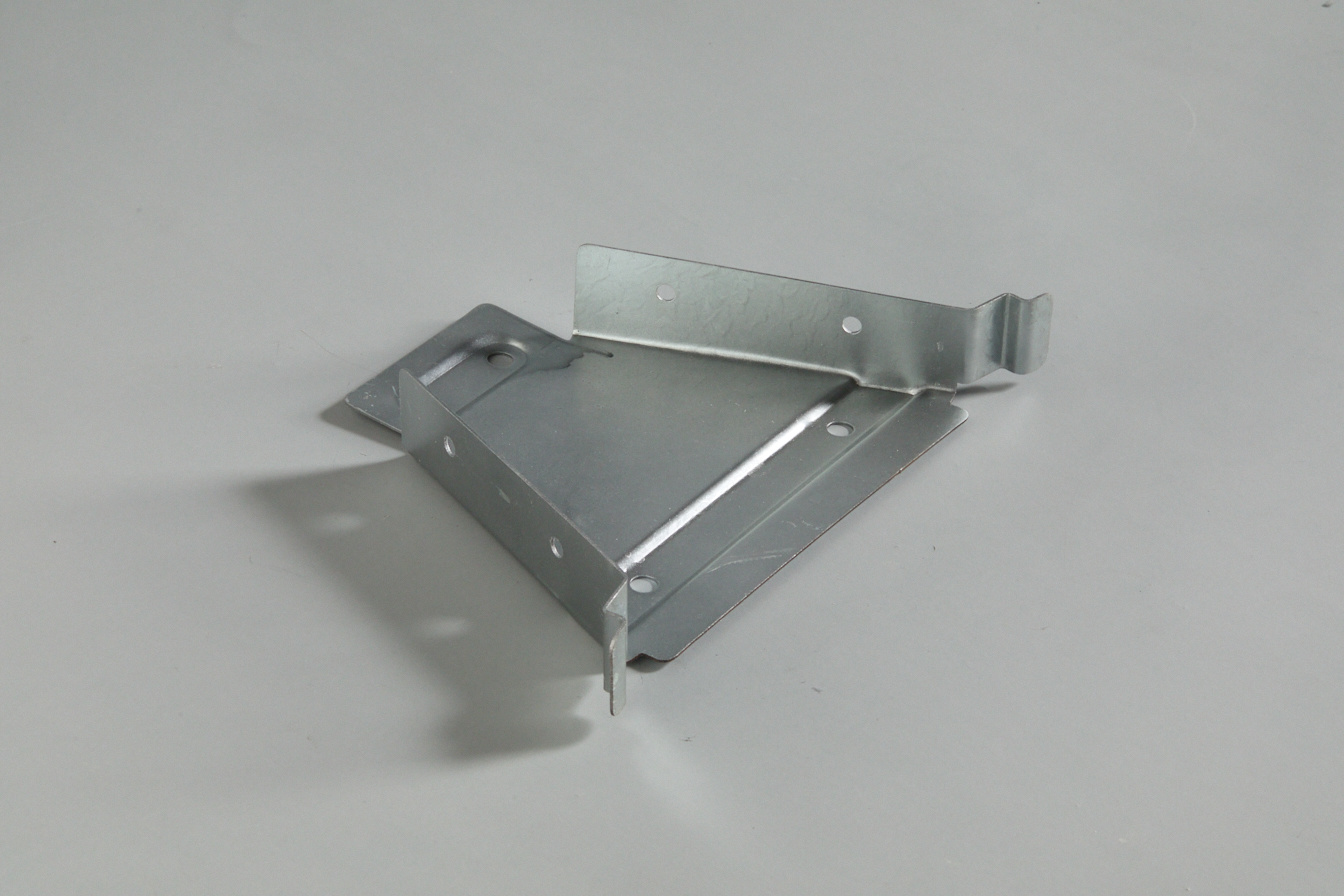

Steel is one of the most commonly used materials for T-shaped column connectors due to its high tensile strength and durability. It can withstand heavy loads and resist deformation, making it ideal for various structural applications.

4.2 Aluminum

Aluminum is gaining popularity for T-shaped column connectors, particularly in lighter construction projects. It offers excellent corrosion resistance and is easier to handle during installation.

4.3 Composite Materials

Composite materials, which combine the advantages of different substances, are also being used in T-shaped column connectors. These materials can provide enhanced strength while reducing overall weight.

5. Applications of T-Shaped Column Connectors

T-shaped column connectors find applications in various construction projects, reflecting their versatility and effectiveness.

5.1 Residential Buildings

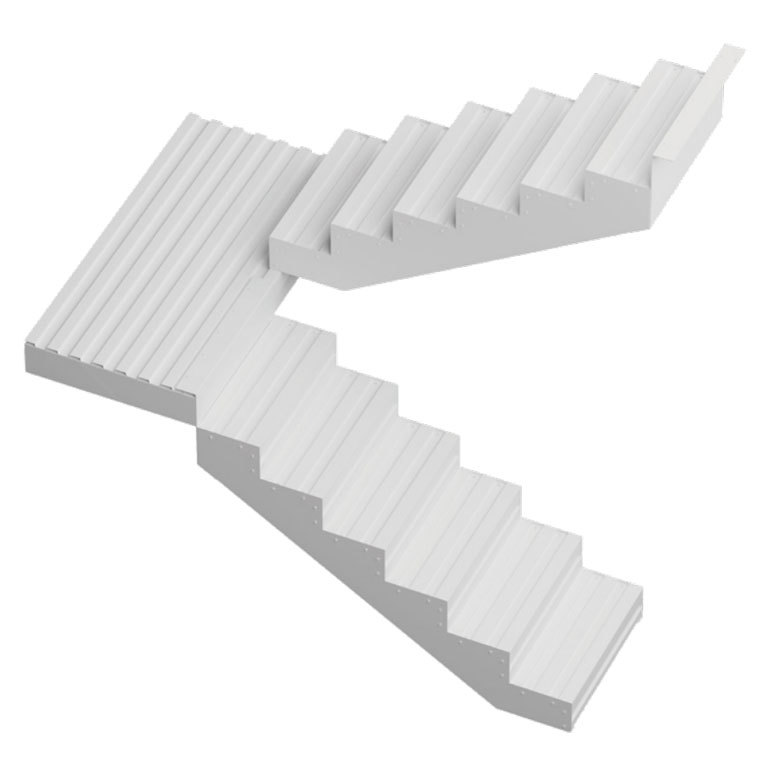

In residential construction, T-shaped column connectors are often used to support multi-story structures, ensuring stability and safety.

5.2 Commercial Structures

For commercial buildings, these connectors are essential in large open spaces, providing the necessary support for expansive ceilings and roofs.

5.3 Infrastructure Projects

T-shaped column connectors are widely utilized in the construction of bridges and overpasses, where they help carry the substantial loads associated with vehicular traffic.

6. Benefits of Using T-Shaped Column Connectors

Using T-shaped column connectors presents numerous benefits that enhance both construction efficiency and structural performance.

6.1 Enhanced Stability

These connectors significantly improve the overall stability of structures, particularly during seismic events or high winds, thereby increasing safety for occupants.

6.2 Flexible Design Options

T-shaped column connectors allow for greater design flexibility, enabling architects to create innovative and complex structures without compromising on safety.

6.3 Cost-Effectiveness

When used correctly, T-shaped column connectors can reduce material waste and labor costs, contributing to more economical construction processes.

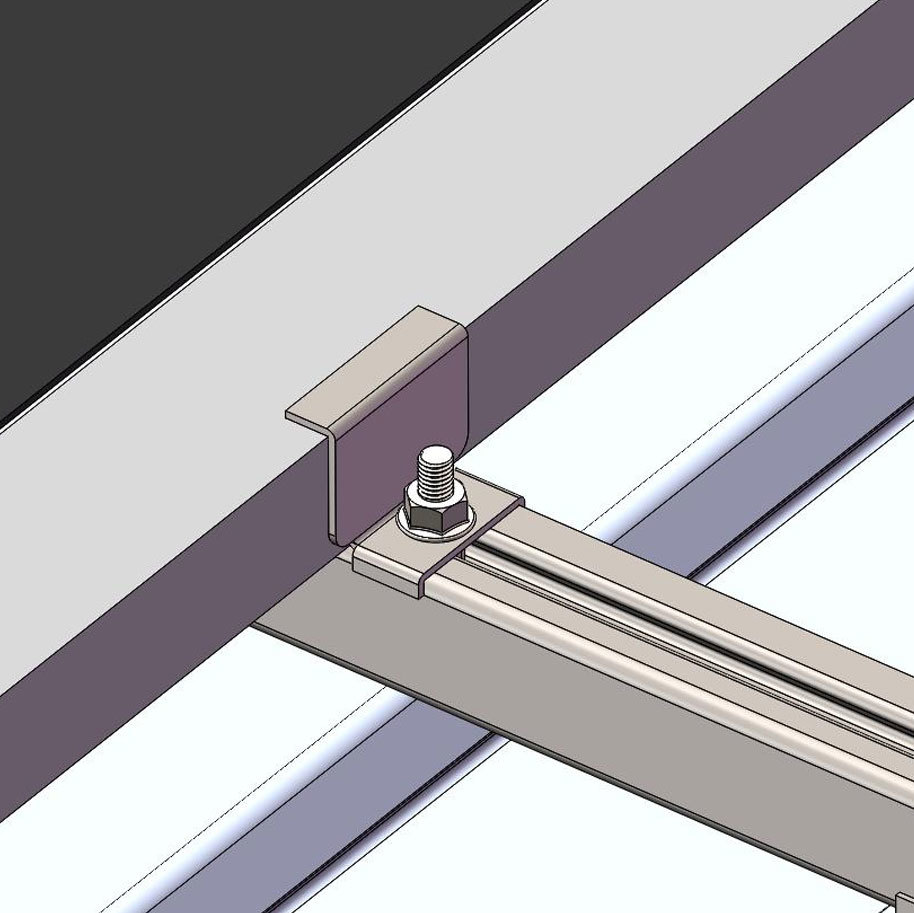

7. Installation Guidelines for T-Shaped Column Connectors

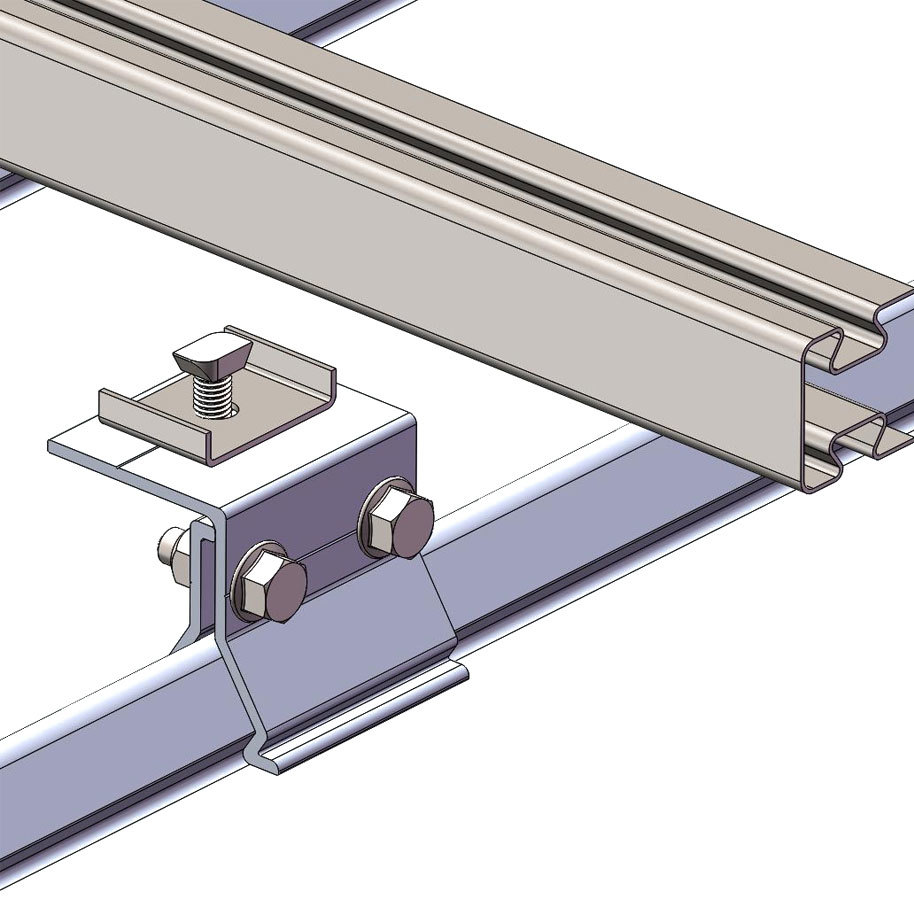

Proper installation of T-shaped column connectors is critical to their performance. Following industry standards and guidelines ensures a safe and effective connection.

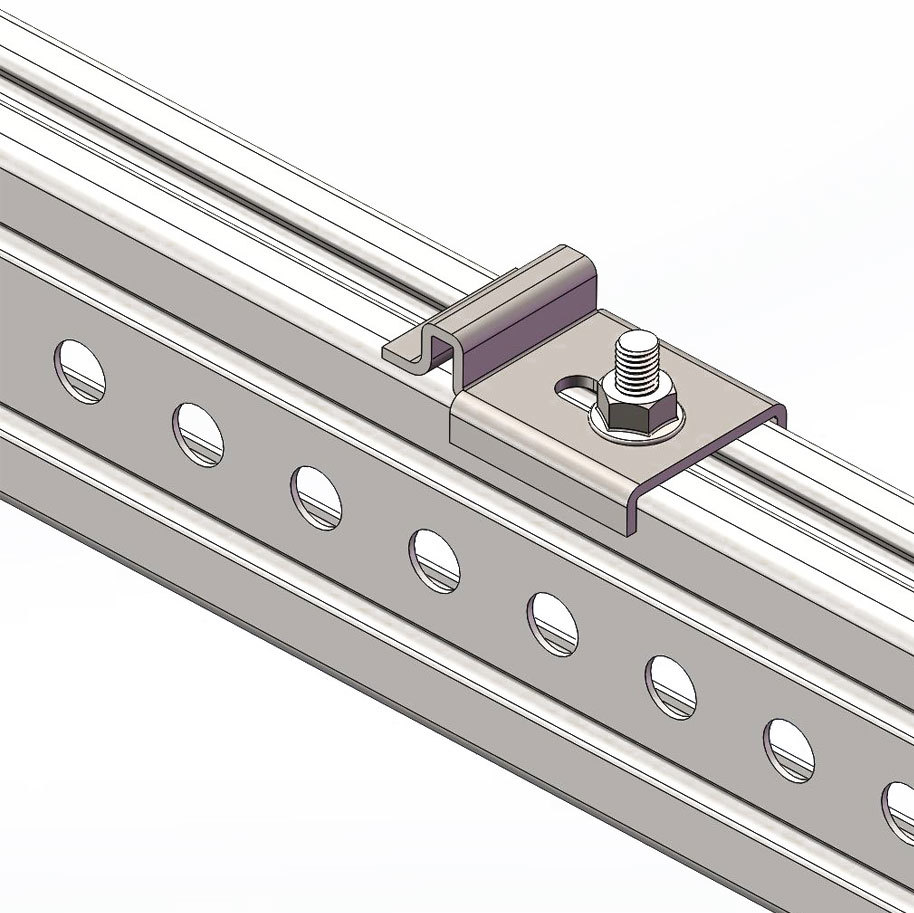

7.1 Pre-Installation Inspection

Before installation, it's essential to inspect all components for defects, ensuring that the connectors meet quality standards.

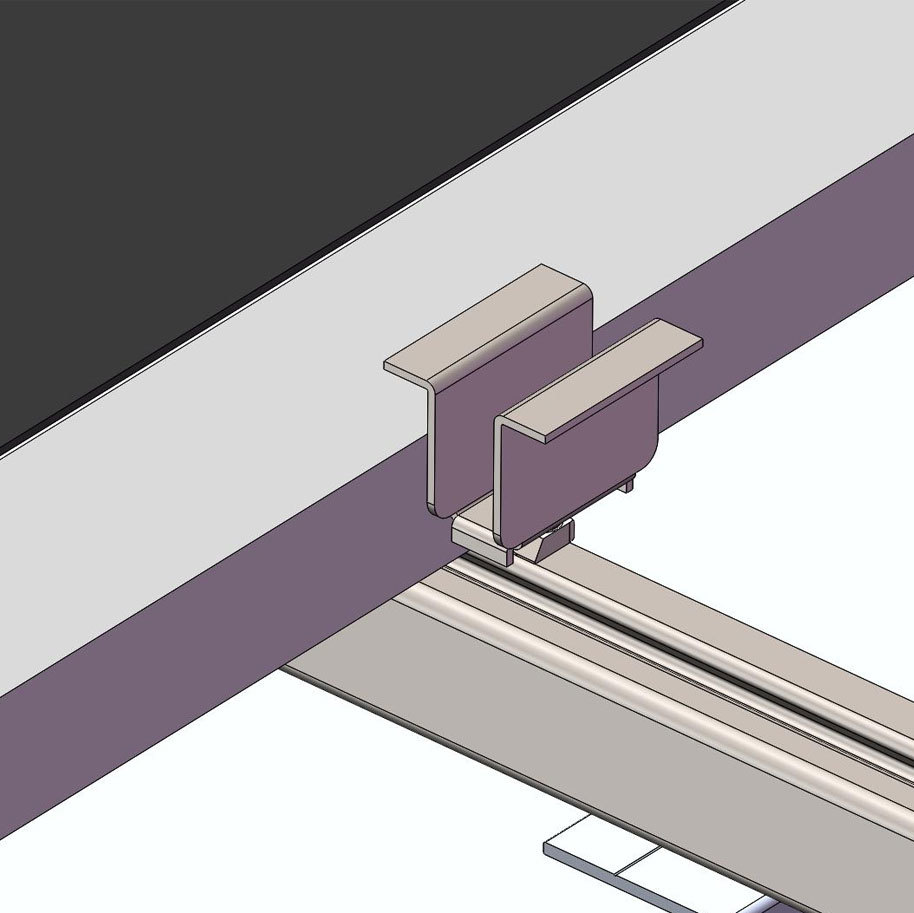

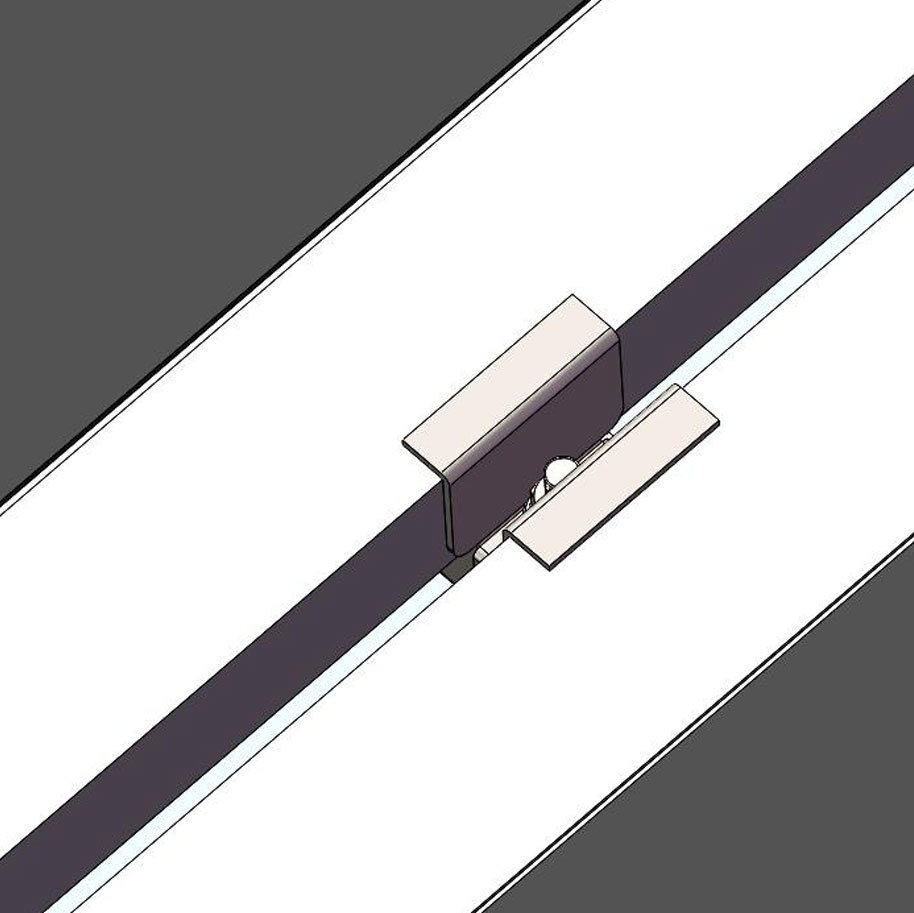

7.2 Alignment and Positioning

Accurate alignment and positioning are vital during installation. Misalignment can lead to structural weaknesses and potential failure.

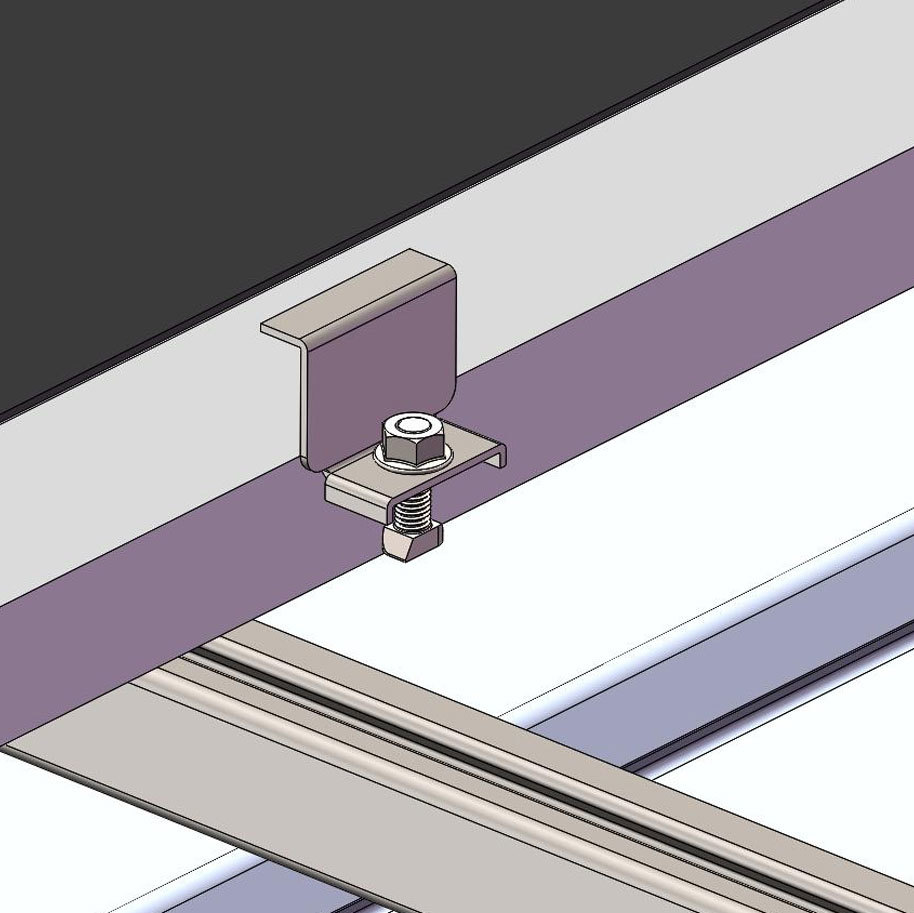

7.3 Secure Fastening Techniques

Using appropriate fastening methods is crucial for ensuring the durability of T-shaped column connectors. This may include welding, bolting, or using adhesive materials, depending on the connector's design and material.

8. Maintenance and Inspection of T-Shaped Column Connectors

Regular maintenance and inspection of T-shaped column connectors are essential for ensuring their longevity and performance.

8.1 Routine Inspections

Conducting routine inspections can help identify any signs of wear or damage early, allowing for timely repairs or replacements.

8.2 Environmental Considerations

Assessing environmental factors, such as exposure to moisture or chemicals, is crucial for maintaining T-shaped connectors, especially those made from steel or aluminum.

8.3 Documentation of Maintenance Activities

Keeping detailed records of maintenance activities aids in tracking the performance of T-shaped column connectors and planning future upkeep.

9. Conclusion

T-shaped column connectors are indispensable in modern construction, offering a perfect combination of strength, stability, and design flexibility. Through a comprehensive understanding of their functionality, applications, and maintenance, professionals in the construction industry can leverage these connectors to enhance the integrity and safety of their projects. As construction techniques evolve, the role of T-shaped column connectors will remain pivotal in achieving innovative and sustainable architectural designs.

10. Frequently Asked Questions (FAQs)

1. What are T-shaped column connectors made from?

T-shaped column connectors are commonly made from materials like steel, aluminum, and composite materials, each offering unique advantages in strength and durability.

2. How do T-shaped column connectors improve structural stability?

They enhance stability by effectively transferring loads between beams and columns, reducing stress on individual components, especially in multi-story buildings.

3. Can T-shaped column connectors be used in seismic zones?

Yes, T-shaped column connectors can provide enhanced stability and support in seismic zones, making them suitable for use in earthquake-resistant structures.

4. What maintenance is required for T-shaped column connectors?

Routine inspections for wear or damage, along with environmental assessments, are crucial for maintaining the effectiveness of T-shaped column connectors.

5. Are there design limitations for T-shaped column connectors?

While they offer significant design flexibility, it is essential to consider load-bearing capacities and material properties to ensure optimal performance in specific applications.

Previous Page

Related Information

HaoHeng Group

Address: Room 1808, Block A, Vanke Cloud City, Jiemei District, Xiamen City, Fujian Province

Business cooperation:

Business License

Copyright © HaoHeng (FuJian) Building Materials Technology Co, Ltd. All rights reserved